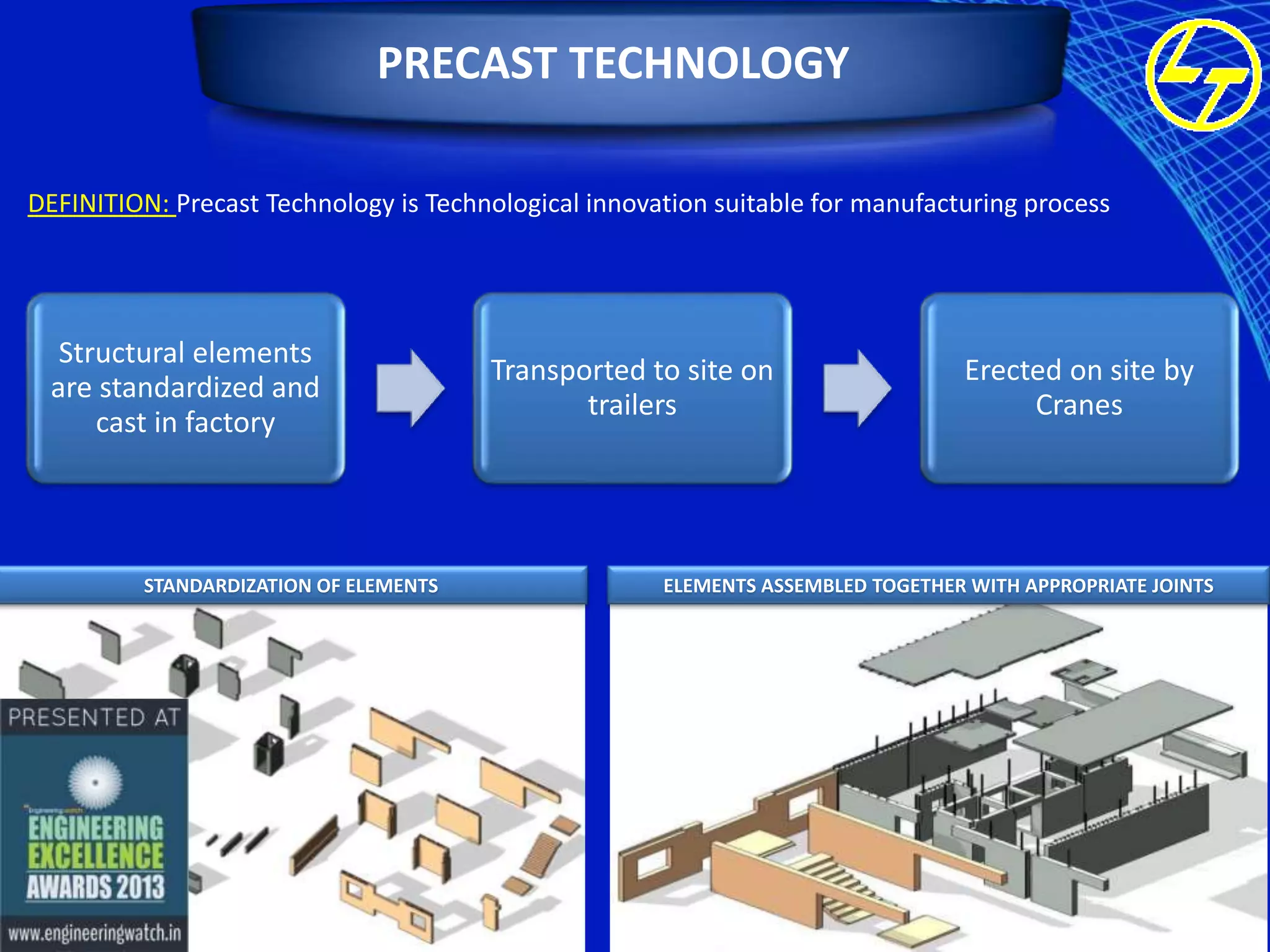

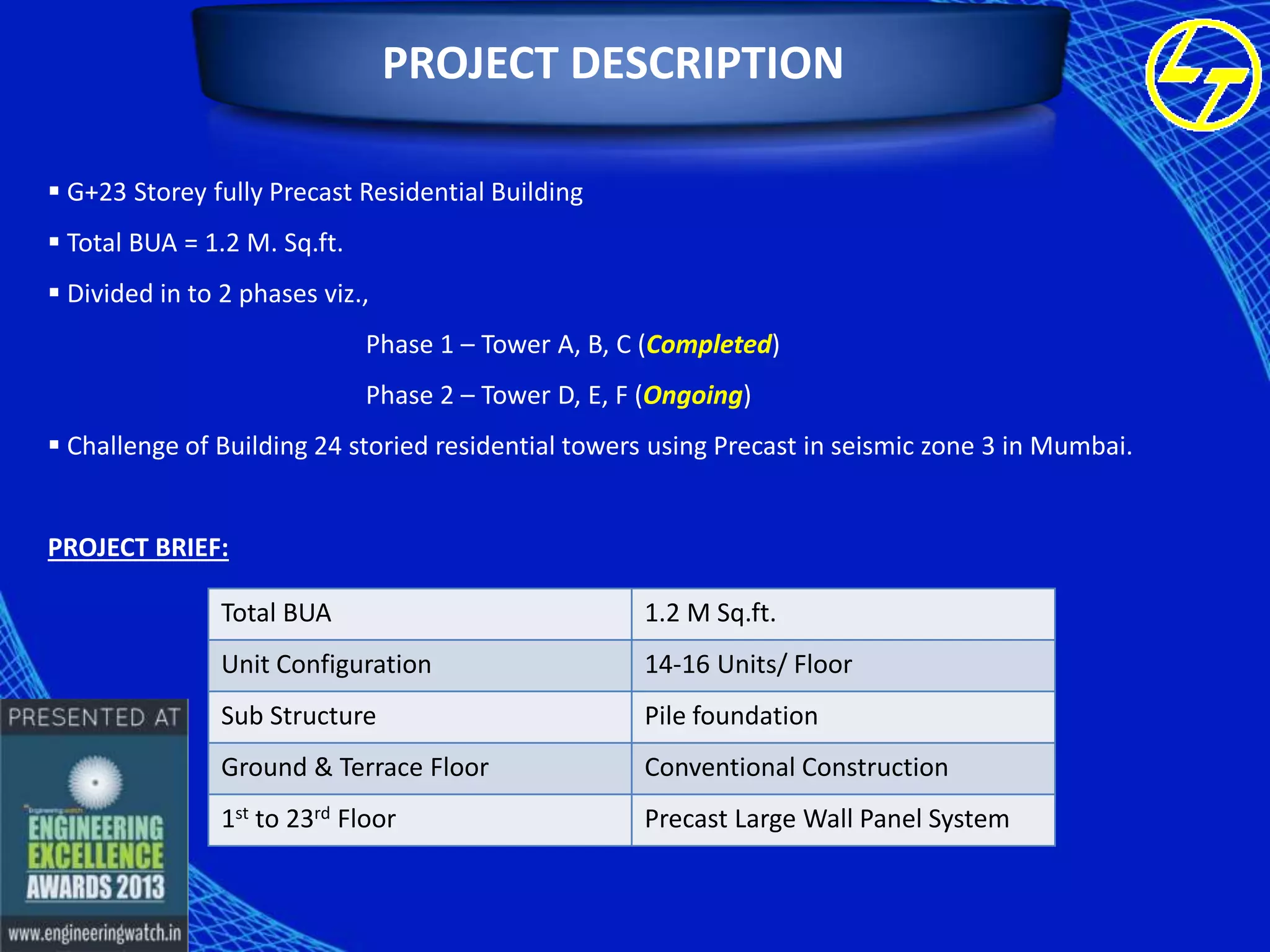

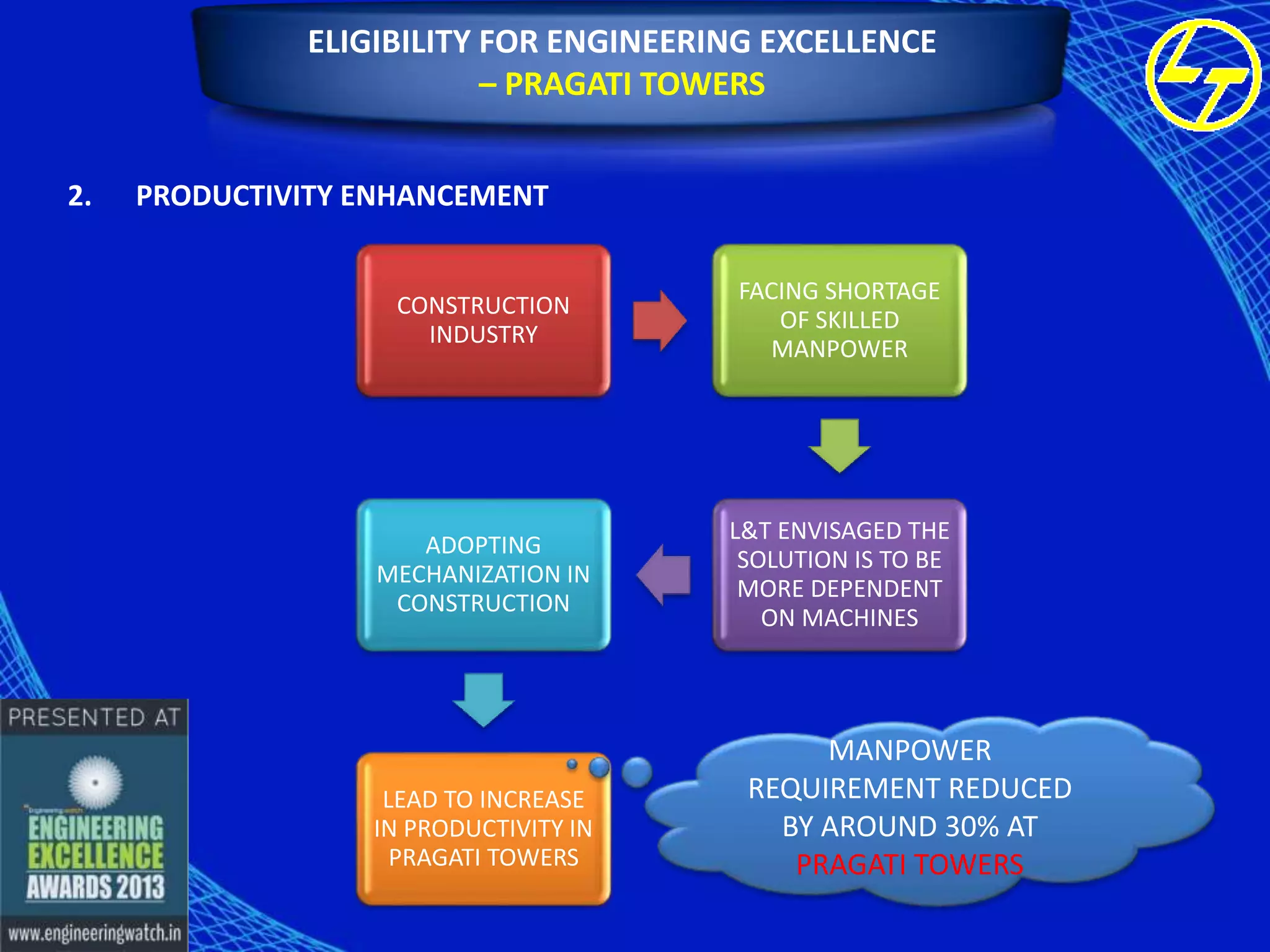

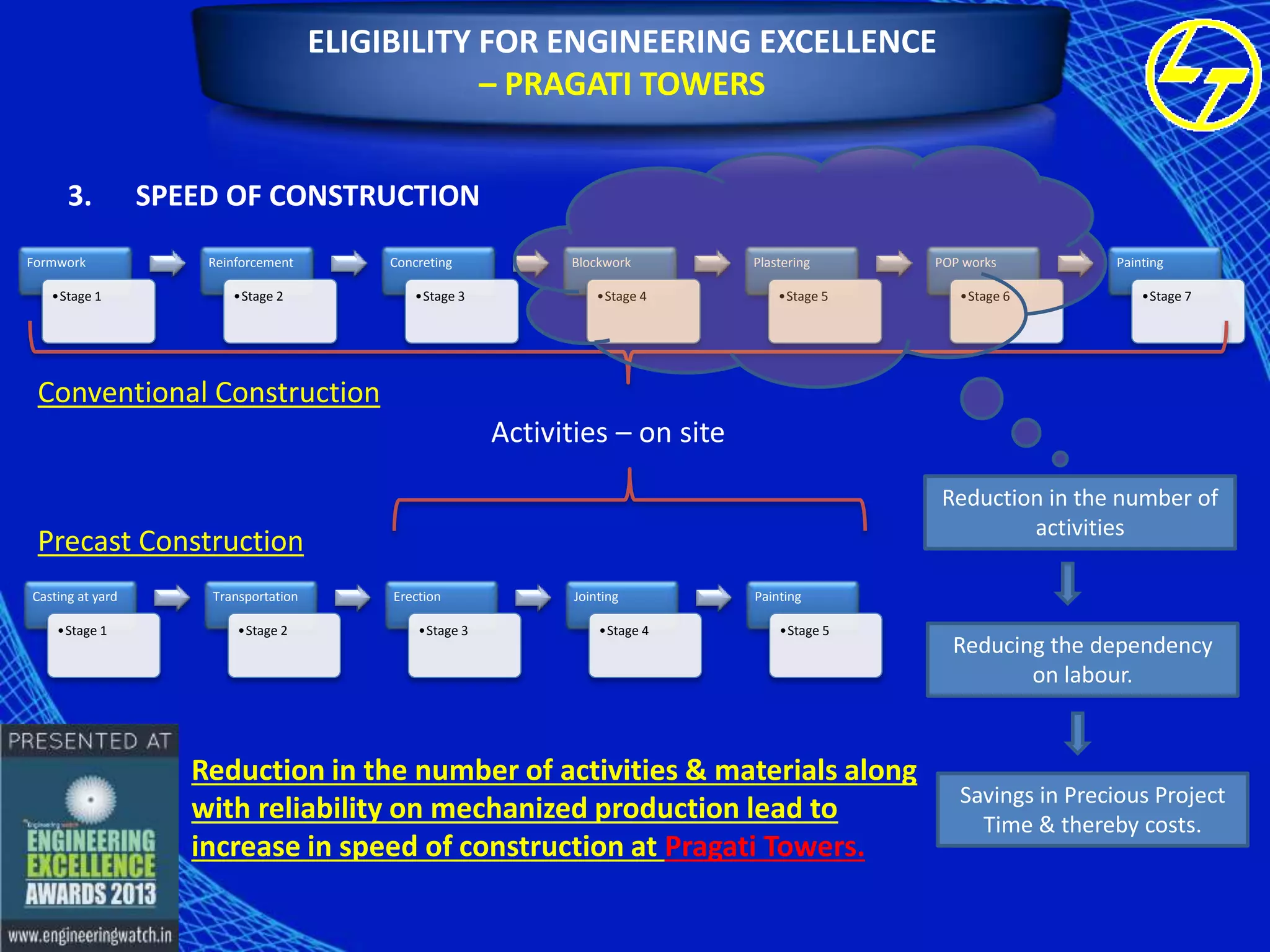

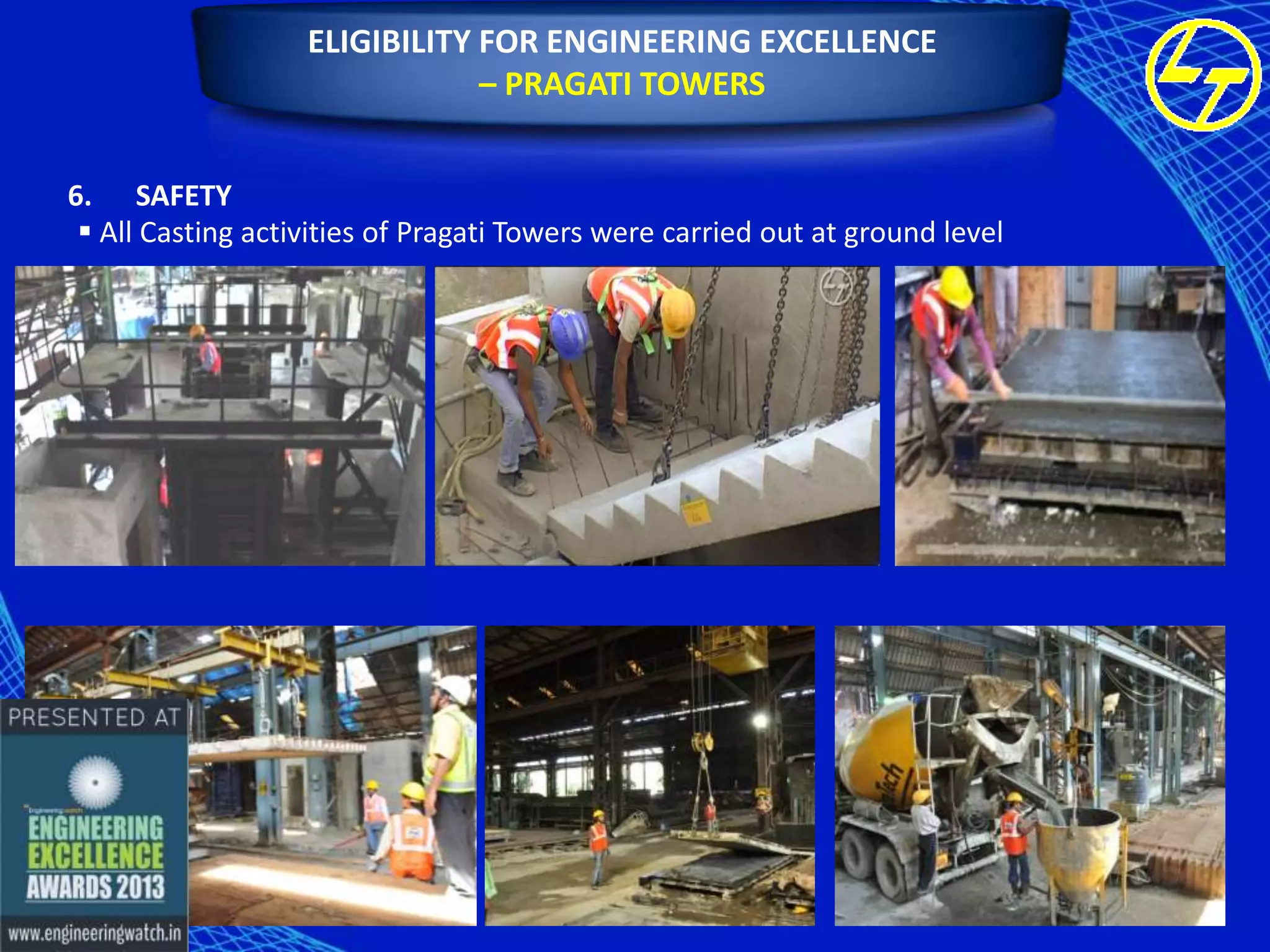

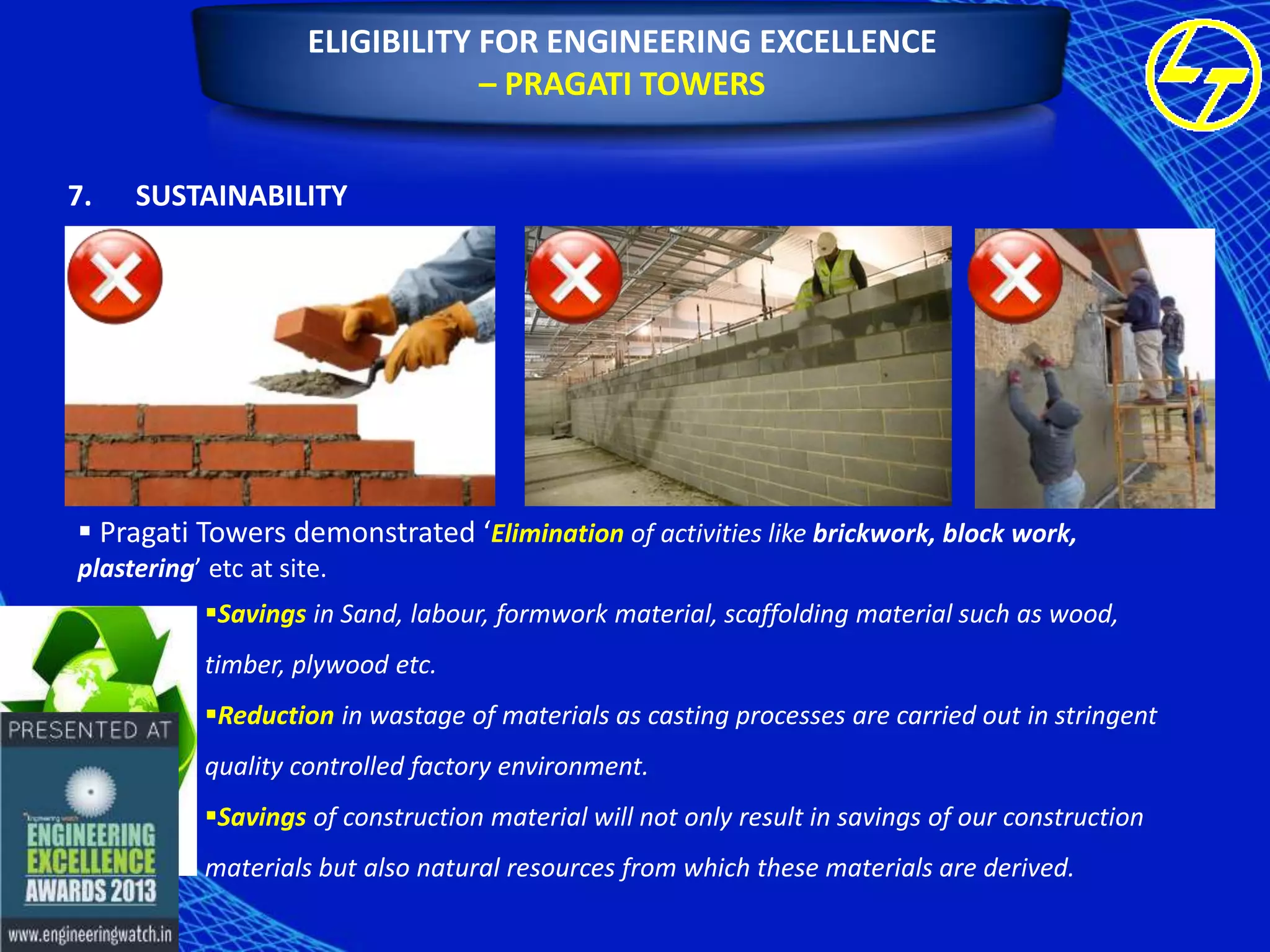

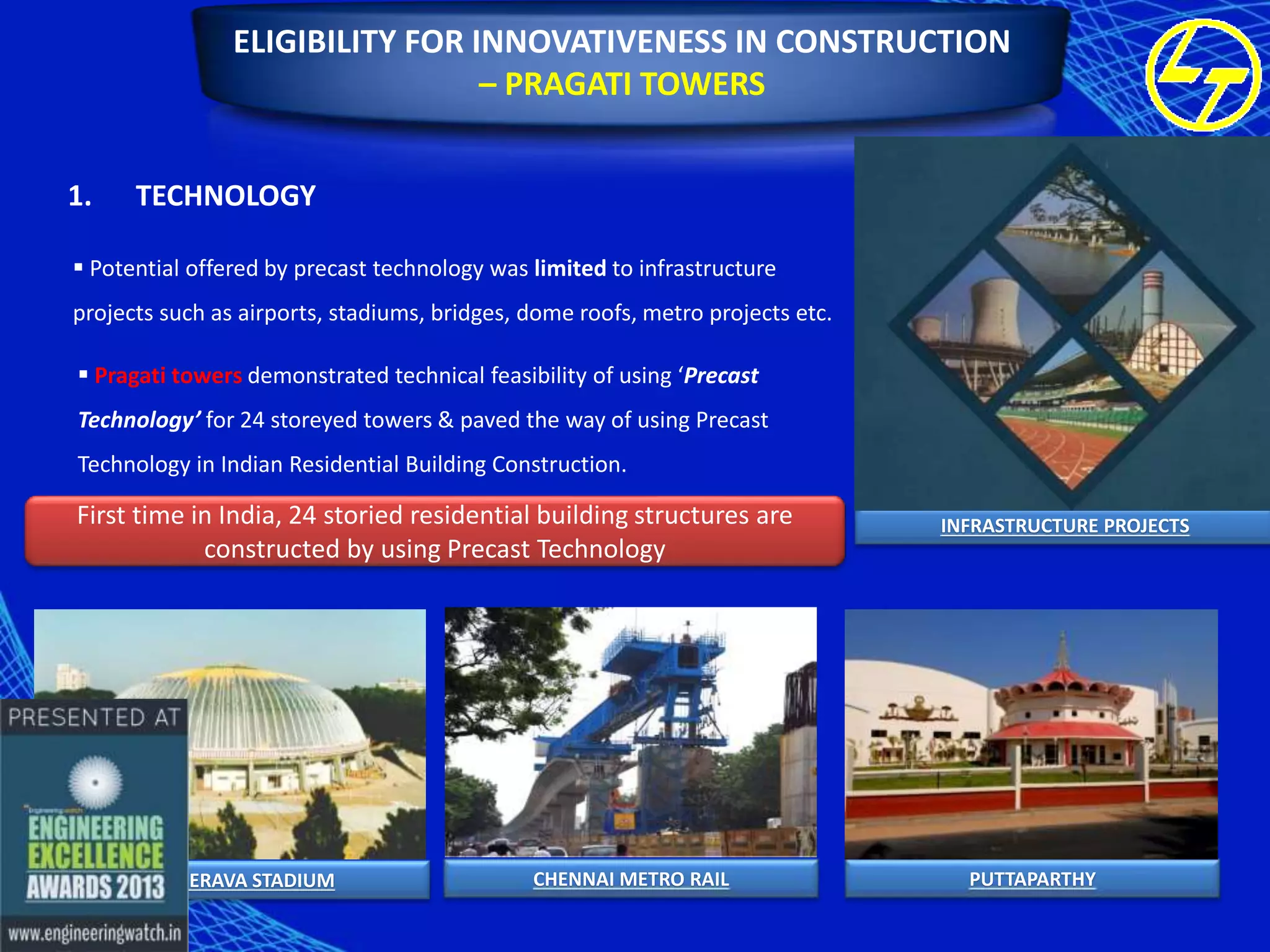

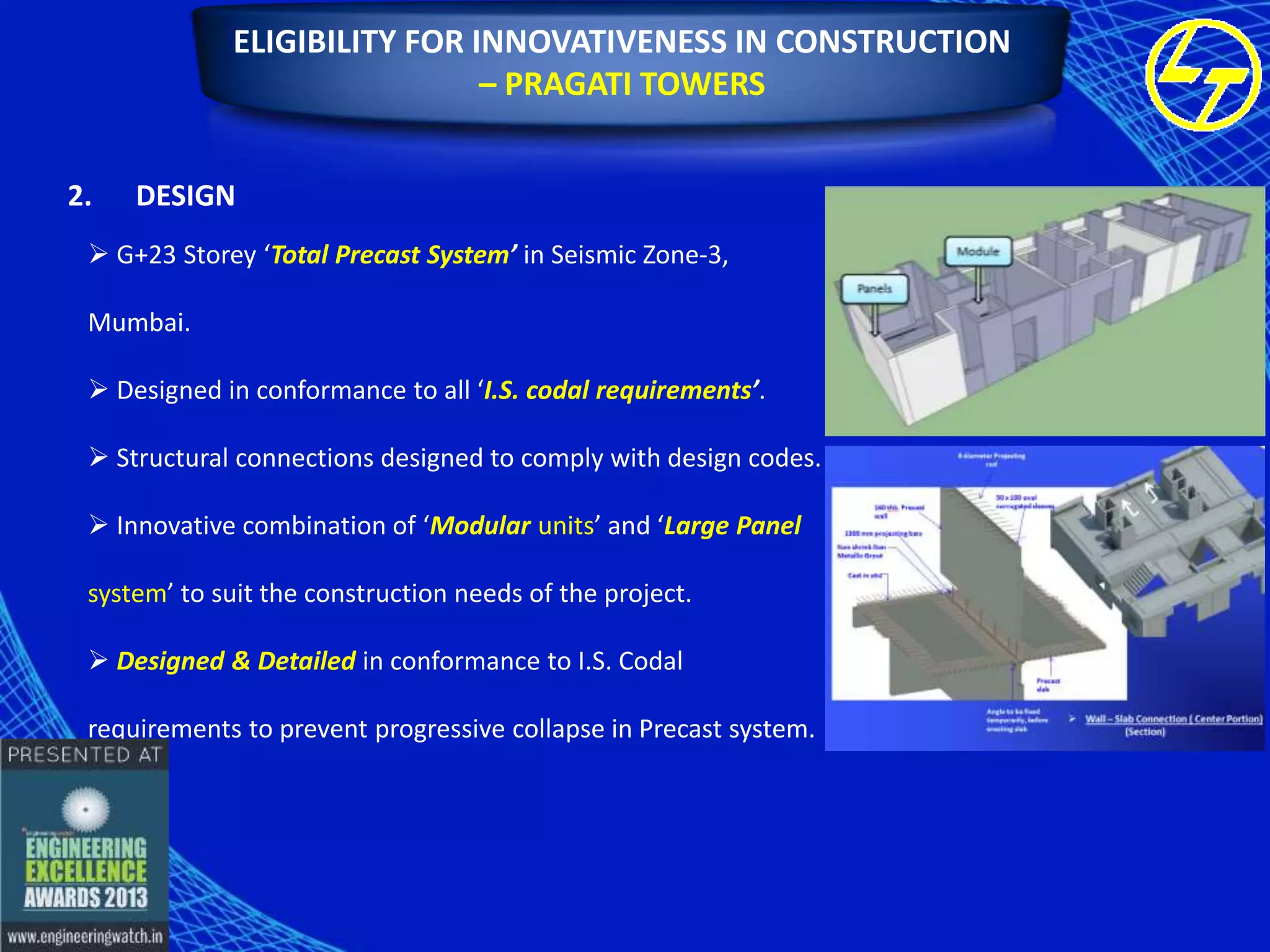

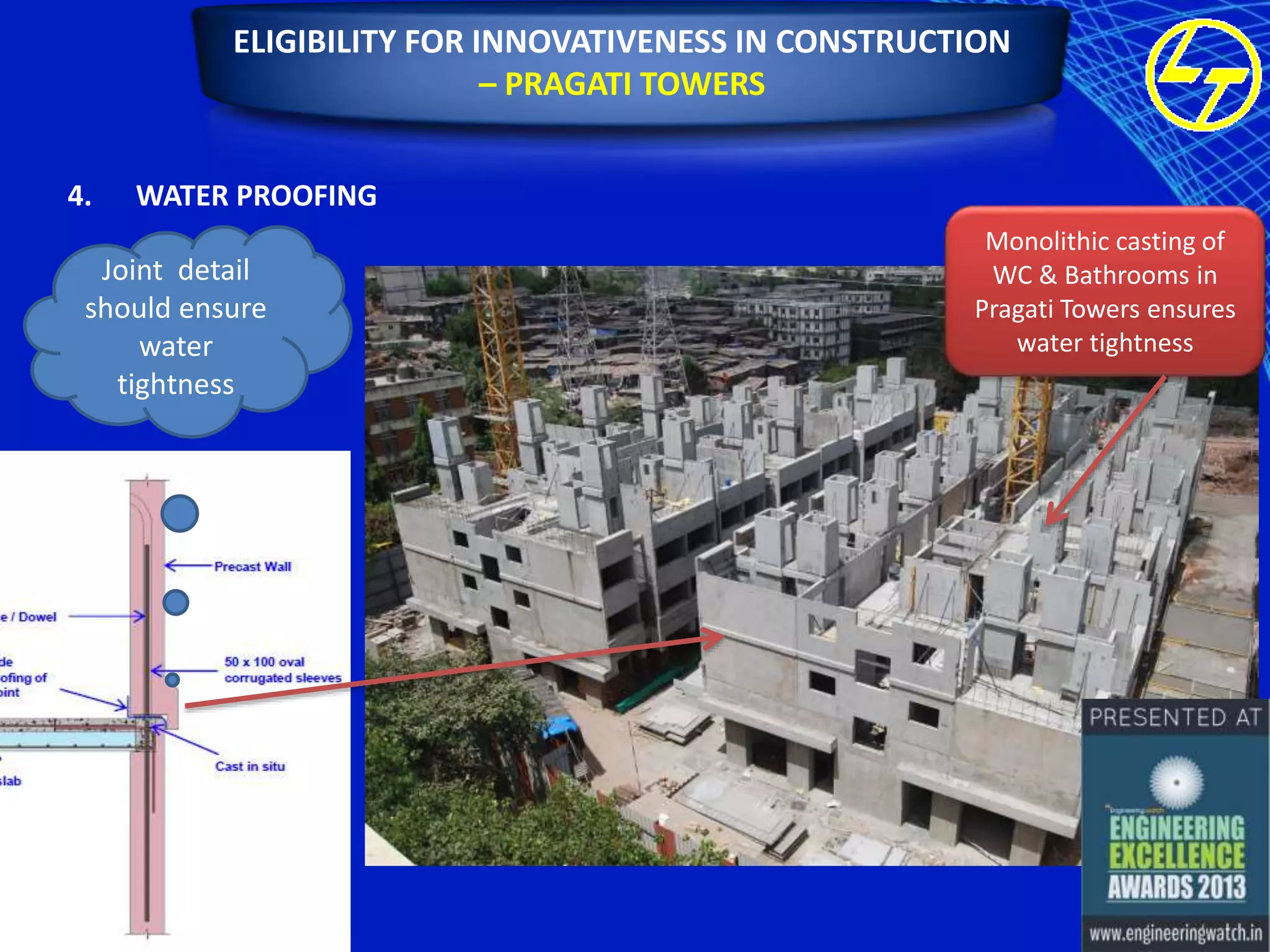

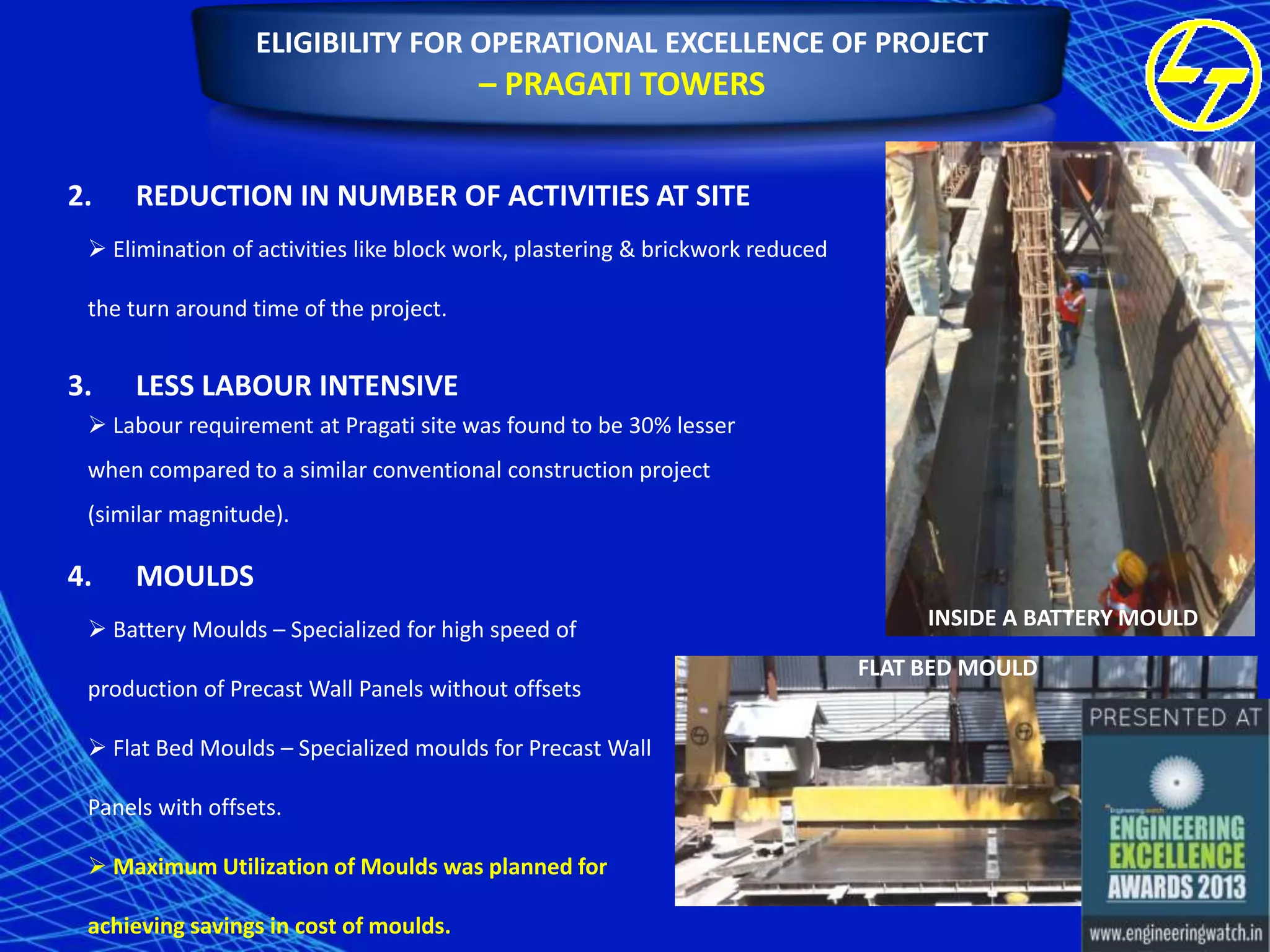

Precast technology was used to construct a 24-story residential building in Mumbai's seismic zone 3 in record time. Standardized precast concrete elements like walls, slabs, and stairs were cast in a factory and assembled on site with joints. The use of precast construction led to increased productivity, speed of construction, quality control, worker safety, and reduced environmental impact compared to traditional construction. This project demonstrated the technical and economic feasibility of using precast technology for high-rise construction in India.