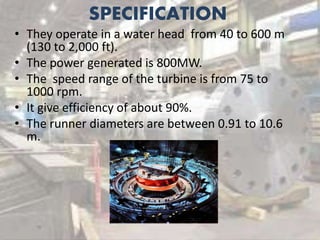

The document provides an overview of hydraulic turbines, including definitions, classifications, and types such as Pelton, Kaplan, and Francis turbines. It details their specifications, working principles, and main components, highlighting differences among the three types in terms of power generation, speed, and efficiency. The Pelton turbine is an impulse type for high heads, Kaplan is a propeller type for low heads, and Francis is an inward-flow reaction turbine suitable for varying head applications.

![CONTENT

1] DEFINATION OF HYDRAULIC TURBINE

2] CLASIFICATION

3] TYPES

3.1] Pelton turbine

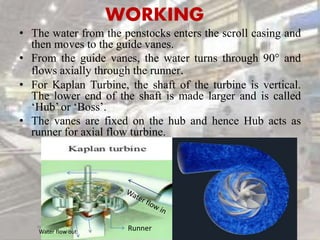

3.2] Kaplan turbine

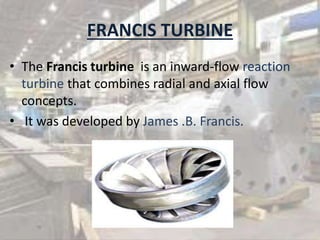

3.3] Francis turbine

4] DIFFERENCE BETWEEN PELTON , KAPLAN ,

FRANCIS TURBINES.](https://image.slidesharecdn.com/hydraulicturbines-170212043632/85/Hydraulic-turbines-2-320.jpg)

![MAIN COMPONENTS

1] Nozzle and spear

2] Runner and bucket

3] Casing

4] Breaking jet

1] Nozzle :- It controls the amount of water striking

the vanes of runner.

2] Casing :- It is used to prevent splashing of

water.](https://image.slidesharecdn.com/hydraulicturbines-170212043632/85/Hydraulic-turbines-8-320.jpg)

![3] Runner and Bucket :- It is circular disc on the

periphery on which evenly spaced bucket are

fixed.

4] Breaking jet :- Its function is to stop the

runner in a short time period.](https://image.slidesharecdn.com/hydraulicturbines-170212043632/85/Hydraulic-turbines-9-320.jpg)

![SR NO. STATION POWER

GENERATED[MW]

1 AMBALA CANTT[INDIA] 800

2 BIEUDRON[SWISS] 1269

3 CASTAIC [US] 1500](https://image.slidesharecdn.com/hydraulicturbines-170212043632/85/Hydraulic-turbines-13-320.jpg)

![THE MAIN COMPONENTS ARE :-

1] Scroll casing

2] Guide vanes

3] Draft tube

4] Runner

5] Hub

1] Scroll casing: It is the casing which guides the

water and control the water passage.

2] Guide vanes : It is the vanes which guide the

water and perform same function that by scroll.](https://image.slidesharecdn.com/hydraulicturbines-170212043632/85/Hydraulic-turbines-16-320.jpg)

![3] Draft tube:- It discharges the water to trail

race through gradually expanding tube.

4] Runner :- It is connected to shaft of the

generator.

5] Hub:- It part on which runner is mounted](https://image.slidesharecdn.com/hydraulicturbines-170212043632/85/Hydraulic-turbines-17-320.jpg)

![APLLICATIONS

• The kaplan turbine is used in Indian.

SR

NO.

STATION POWER

GENERATED

[MW]

1. LPH 55

2. KADRA 150

3. KODASSALLI 120

4. ALMATTI 275](https://image.slidesharecdn.com/hydraulicturbines-170212043632/85/Hydraulic-turbines-20-320.jpg)

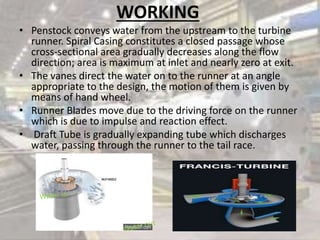

![THE MAIN PARTS ARE :-

1] Spiral casing

2] Guide vanes

3] Runners

4] Draft tube

1] Spiral casing :- It guides the water to the guide

vanes and also control the flow.

2] Guide vanes :- They guide the water to runner

and get closed on increase in flow.](https://image.slidesharecdn.com/hydraulicturbines-170212043632/85/Hydraulic-turbines-23-320.jpg)

![3] Runner :- They are heart of the turbine and

rotate on the impact of flow.

4] Draft tube :- It is place from where the water

is discharged from the turbine](https://image.slidesharecdn.com/hydraulicturbines-170212043632/85/Hydraulic-turbines-24-320.jpg)

![The Francis turbine are used in places

like:-

SR NO . PLACES POWER GENERATION

[MW]

1 Koyna IV (India) 250

2 Turkwell (Kenya) 53

3 Karun (Iran) 250

4 Three Gorges (China) 765](https://image.slidesharecdn.com/hydraulicturbines-170212043632/85/Hydraulic-turbines-27-320.jpg)

![DIFFERENCE BETWEEN

PELTON,KAPLAN,FRANCIS

PARAMETERS PELTON TURBINE KAPLAN TURBINE FRANCIS TURBINE

TYPE OF TURBINE IMPULSE TYPE PROPELLER TYPPE INWARD FLOW

REACTION TYPE

POWER GENRATION

[MW]

400 200 800

SPEED RATE[rpm] 65 - 800 70-429 75 -1000

EFFICIENCY[%] 85 80 90](https://image.slidesharecdn.com/hydraulicturbines-170212043632/85/Hydraulic-turbines-28-320.jpg)