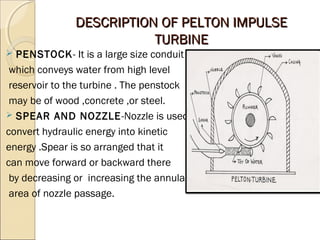

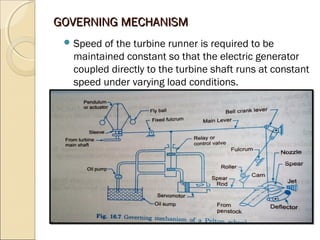

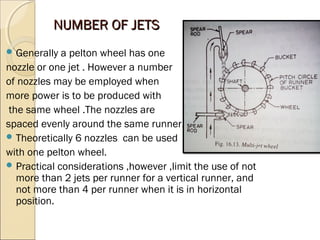

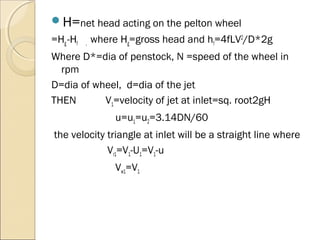

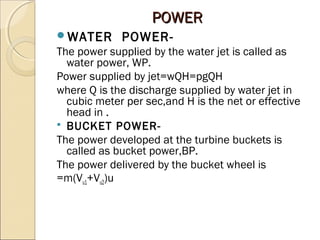

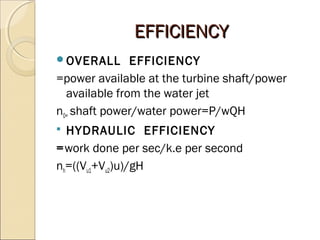

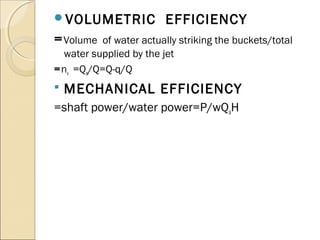

The document discusses the impulse turbine and Pelton wheel turbine. The impulse turbine converts hydraulic energy to kinetic energy using efficient nozzles that direct high velocity jets at buckets on a runner. This changes the jet's direction without pressure change and sets the runner into rotation. A Pelton wheel is a type of impulse turbine that uses free jets and is efficient for heads over 450m. It has a runner with cup-shaped buckets that the high velocity jets from nozzles strike to rotate the shaft and generate power. Key components include the penstock, spear and nozzle, casing, runner and buckets, and governing mechanism.

Human: Thank you, that is a concise 3 sentence summary that captures the key points about impulse turbines and