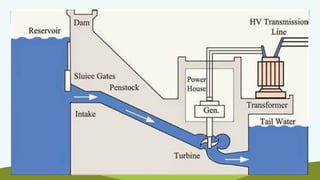

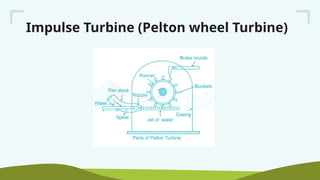

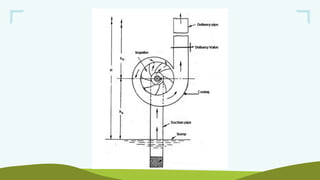

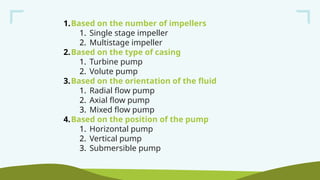

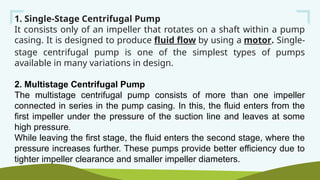

The document provides a comprehensive overview of hydraulic turbines, particularly highlighting their function of converting hydraulic energy to mechanical and subsequently electrical energy in hydroelectric power plants. It details various components, types of hydraulic turbines (including impulse and reaction types), and specifically explains the construction and operation of Pelton and Francis turbines. Additionally, it discusses centrifugal pumps, their components, types, advantages, disadvantages, and applications across different industries.