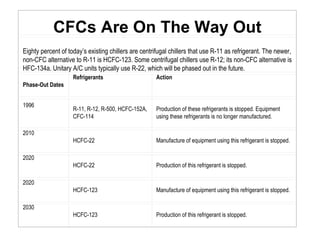

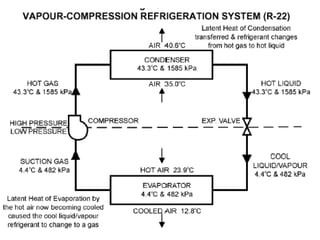

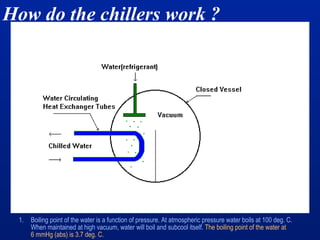

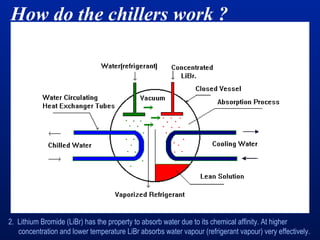

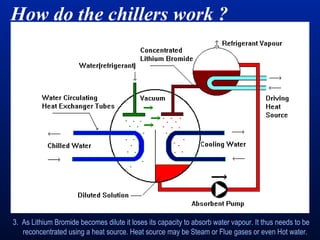

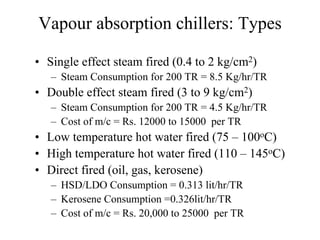

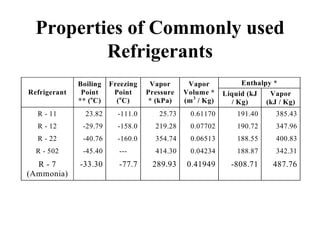

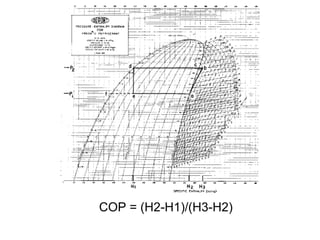

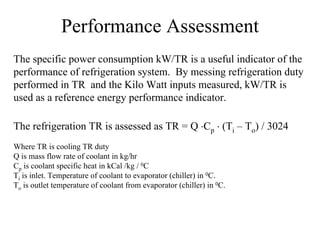

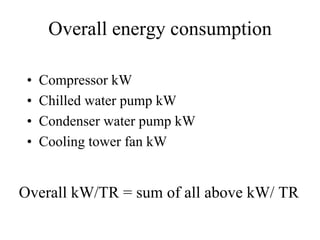

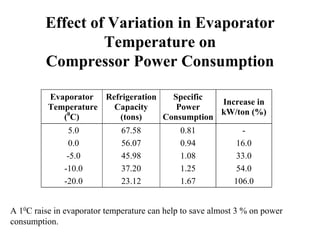

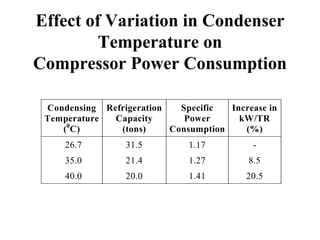

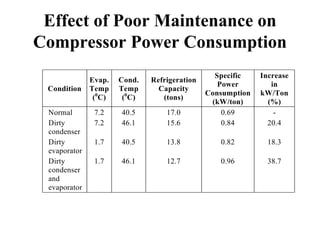

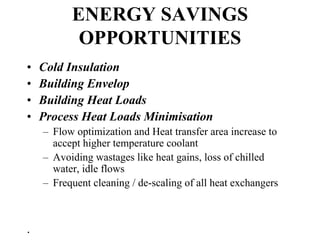

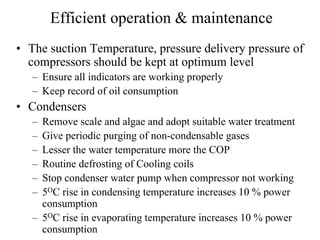

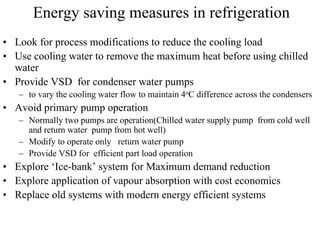

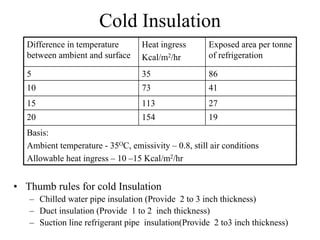

This document discusses HVAC and refrigeration systems. It provides information on types of refrigerants used in centrifugal chillers and unitary AC units. It notes that R-11, R-12 and R-22 are being phased out due to being CFCs and lists phase-out dates for various refrigerants. It also discusses vapor compression systems, properties of commonly used refrigerants, and ways to improve system performance and reduce energy consumption through maintenance and optimization of operating parameters.