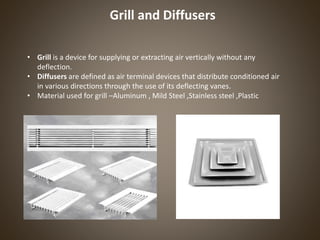

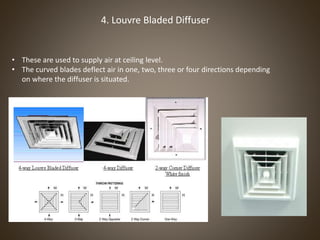

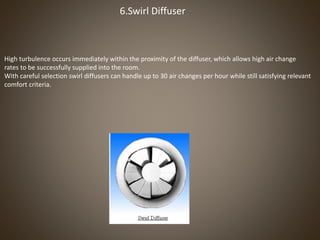

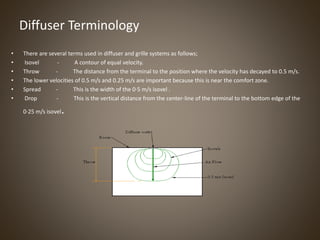

The document discusses the components and design of air distribution systems in HVAC. It describes the different types of ducts based on shape, pressure, velocity, and materials used. Rectangular, round, and oval ducts are common shapes. Ducts can be high, medium, or low pressure and high or low velocity. Common duct materials include galvanized steel, aluminum, pre-insulated, and fabric. Duct joints include slip joints, drive slips, and flange joints. The document also discusses outlet types like grilles and diffusers, as well as air filters used to remove particles from the air flow. Proper sizing and design of ducts, outlets, and filters are important for effective