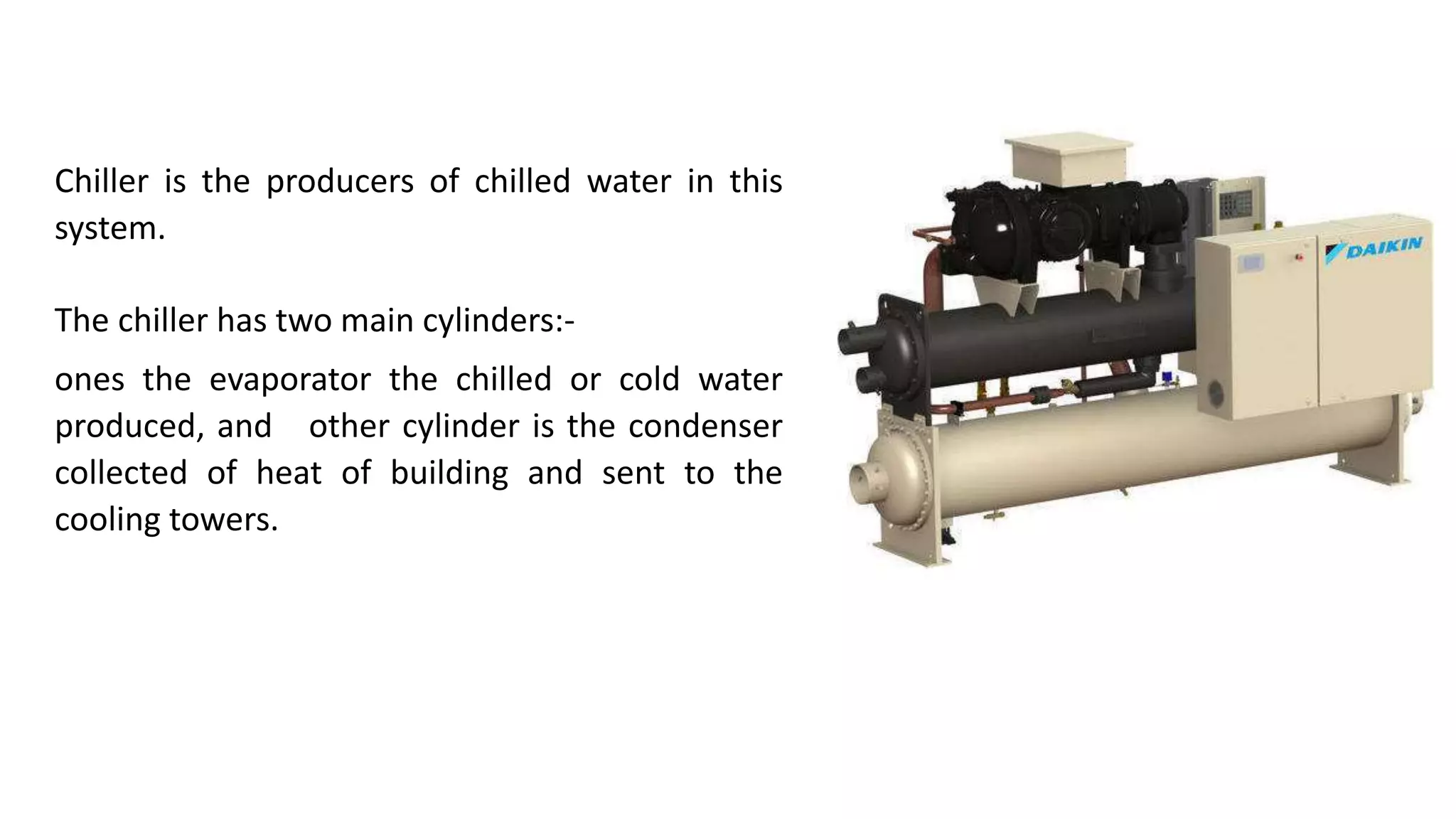

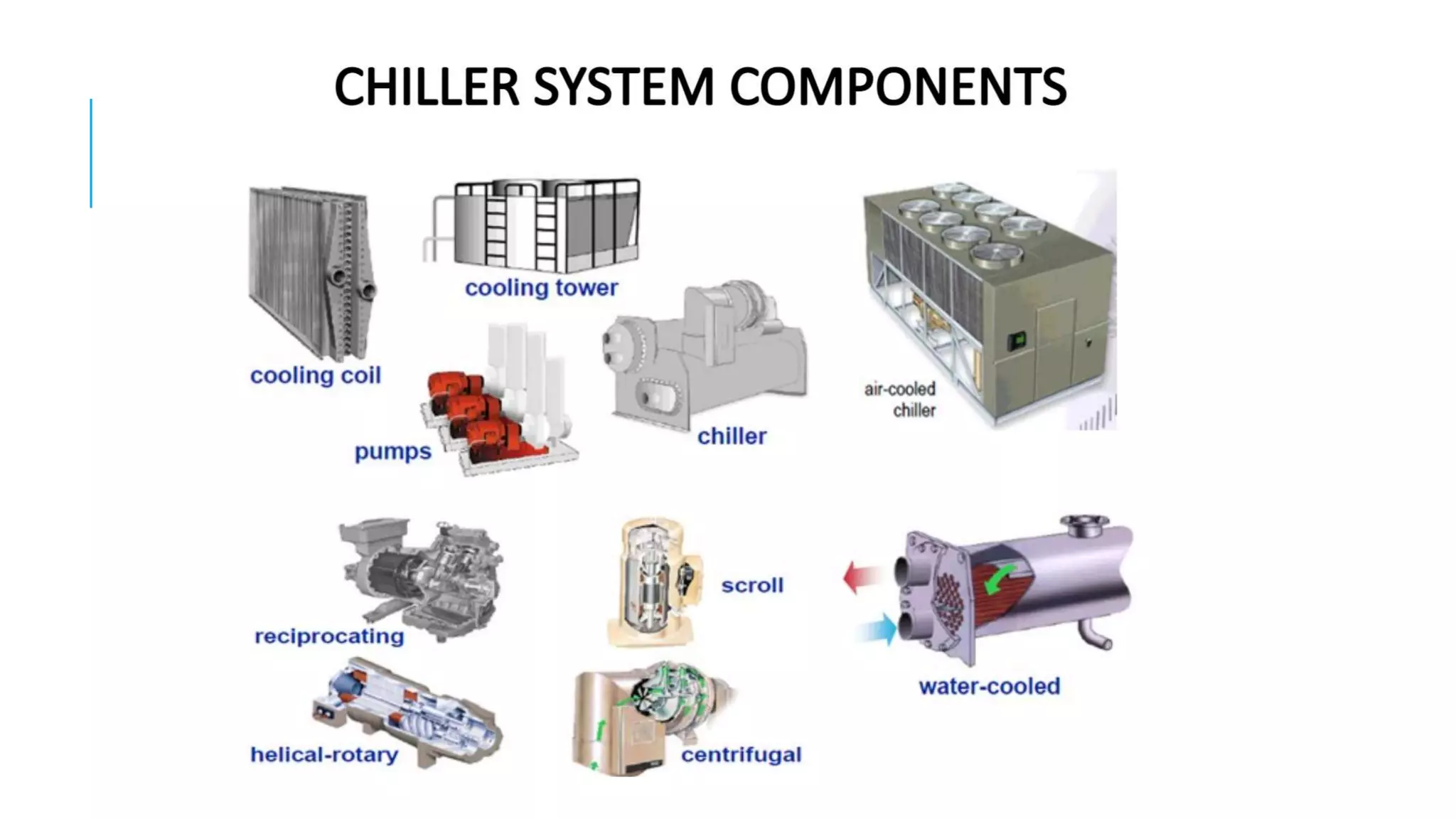

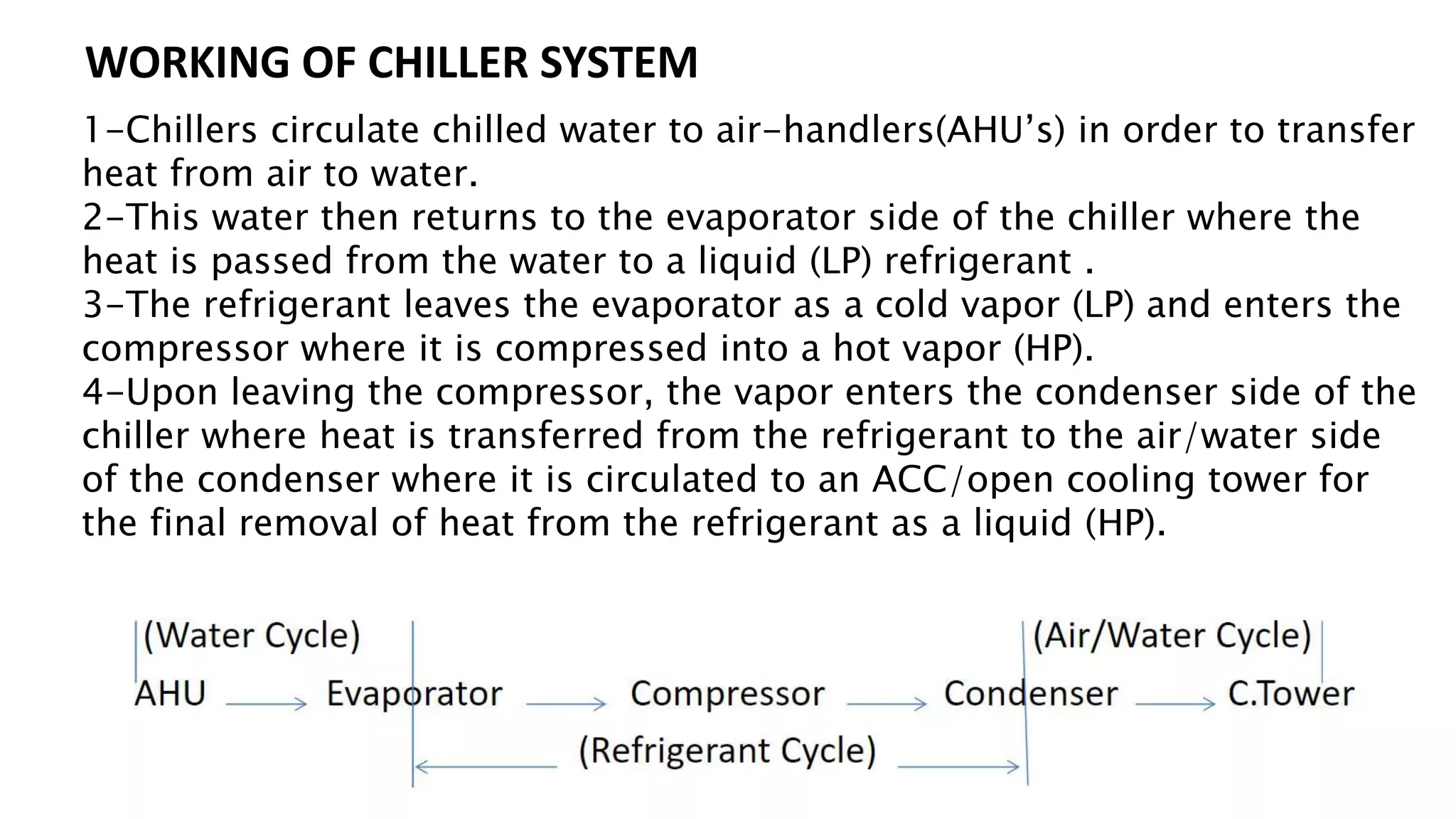

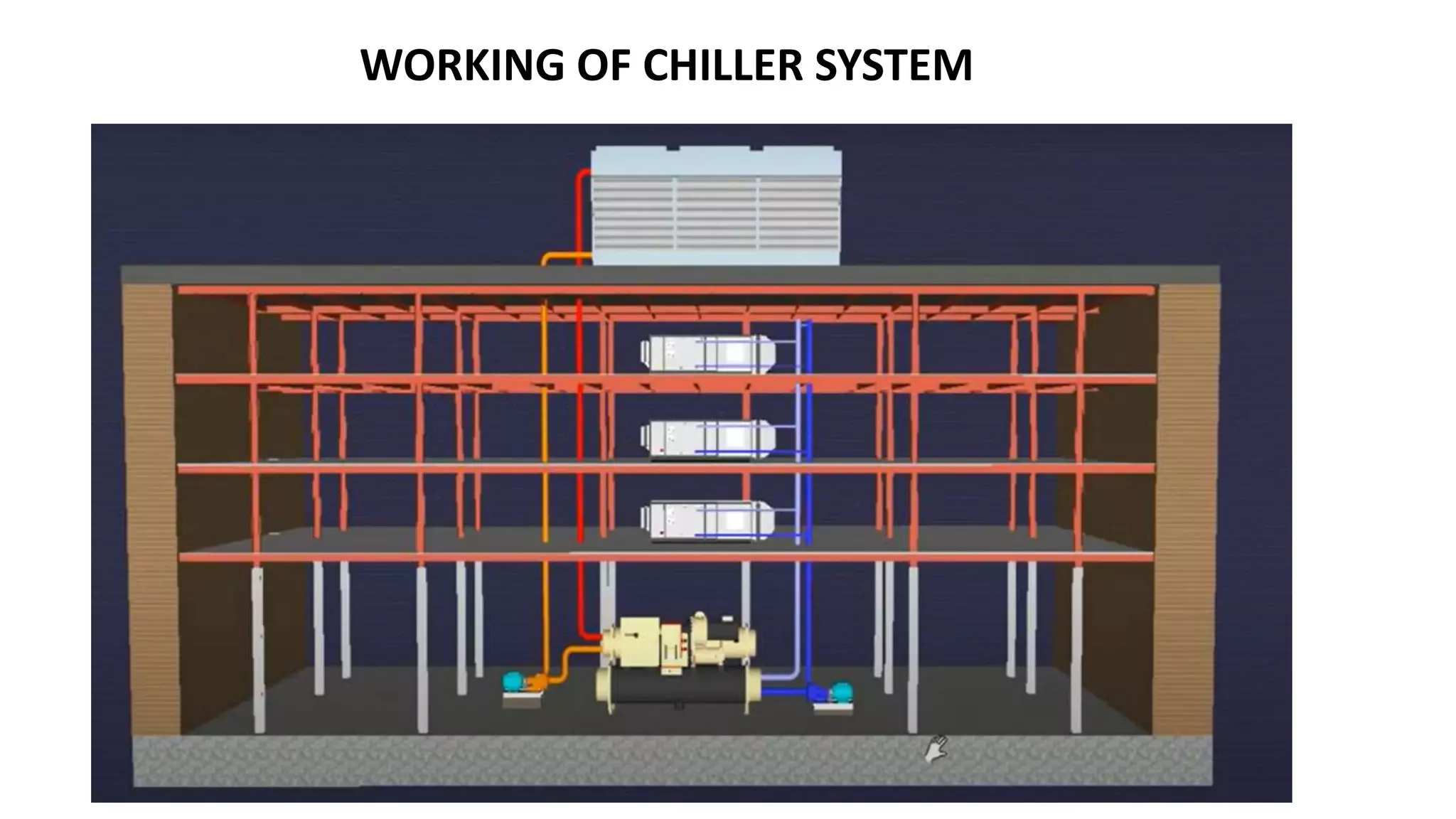

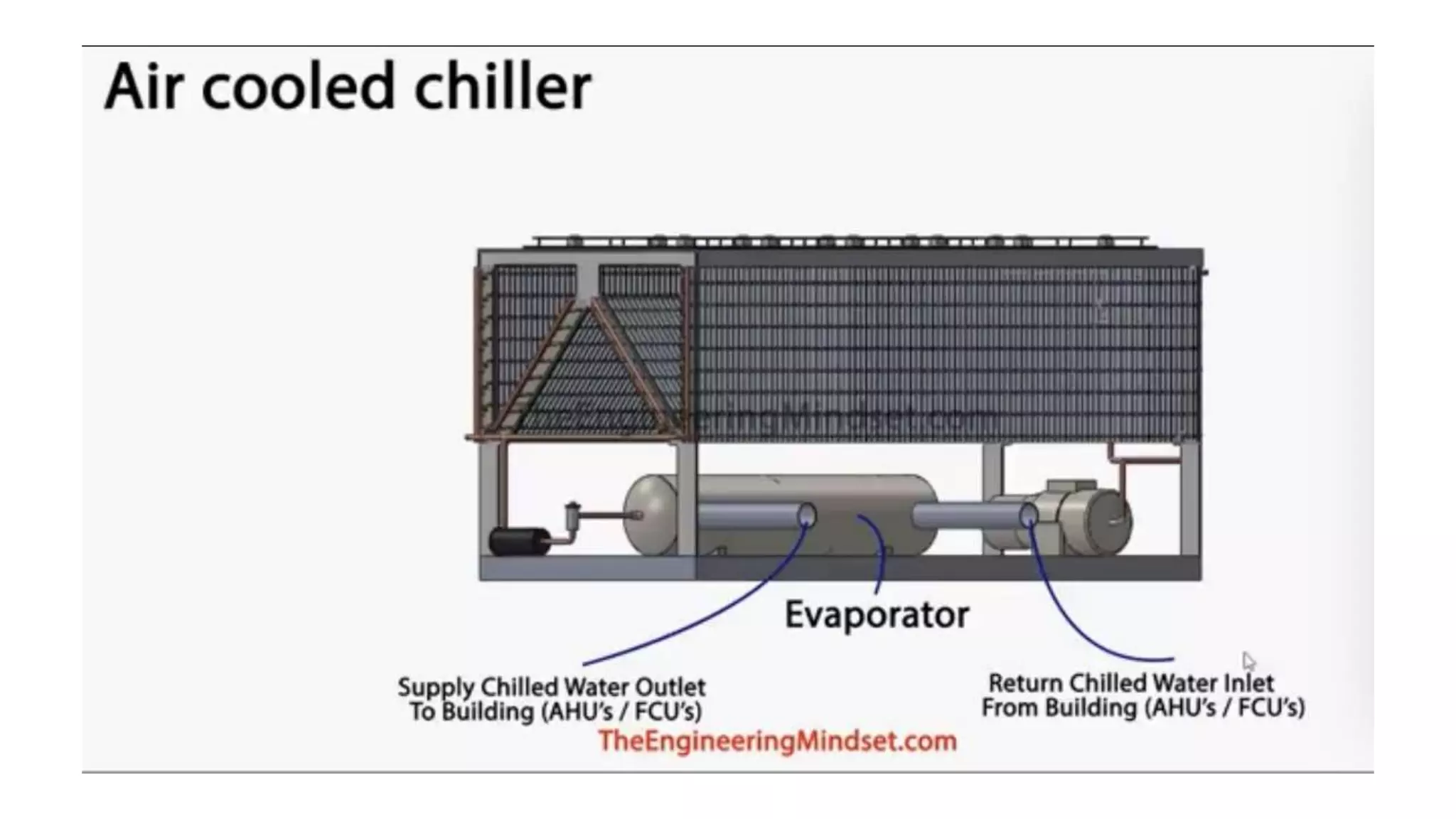

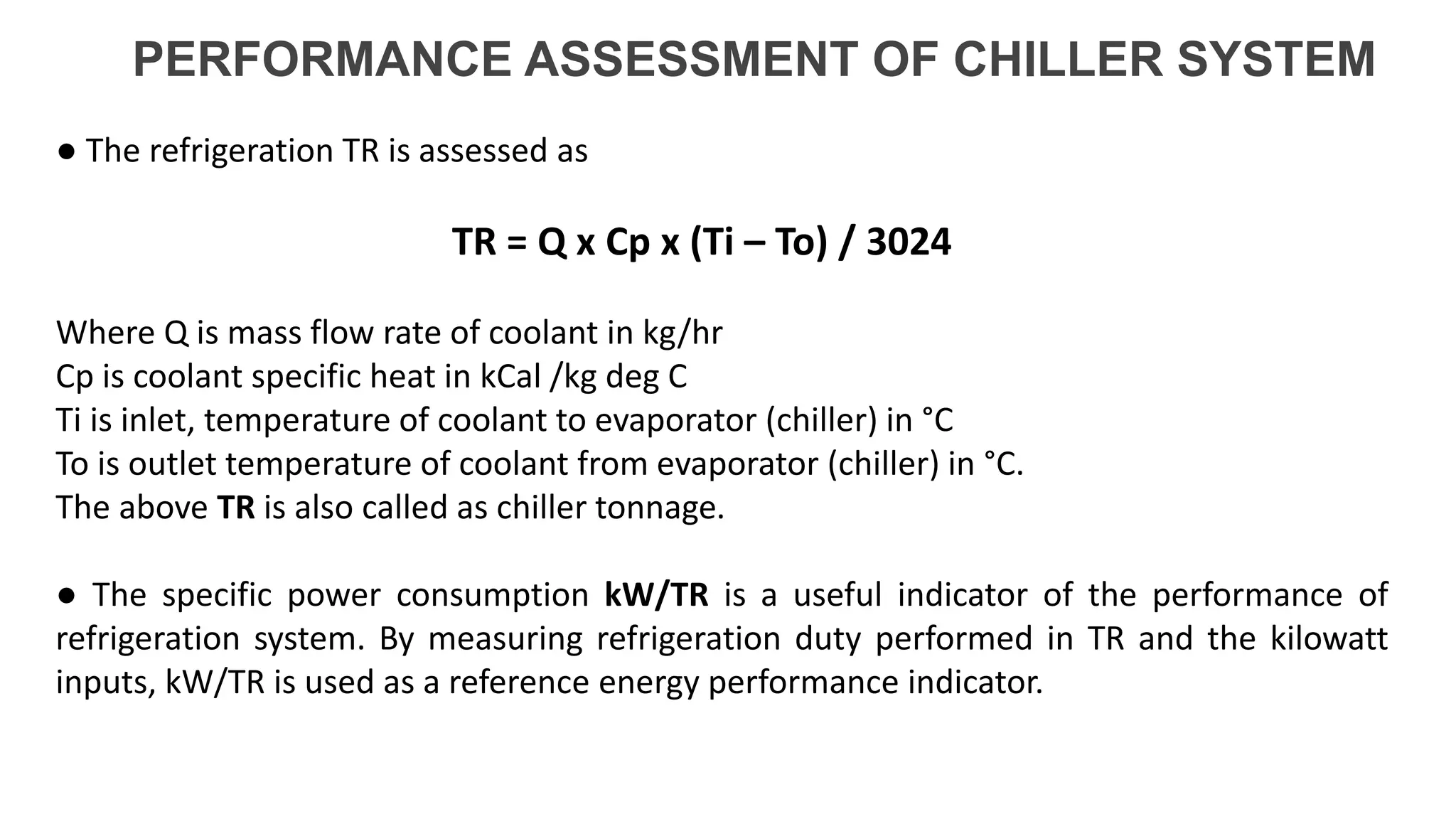

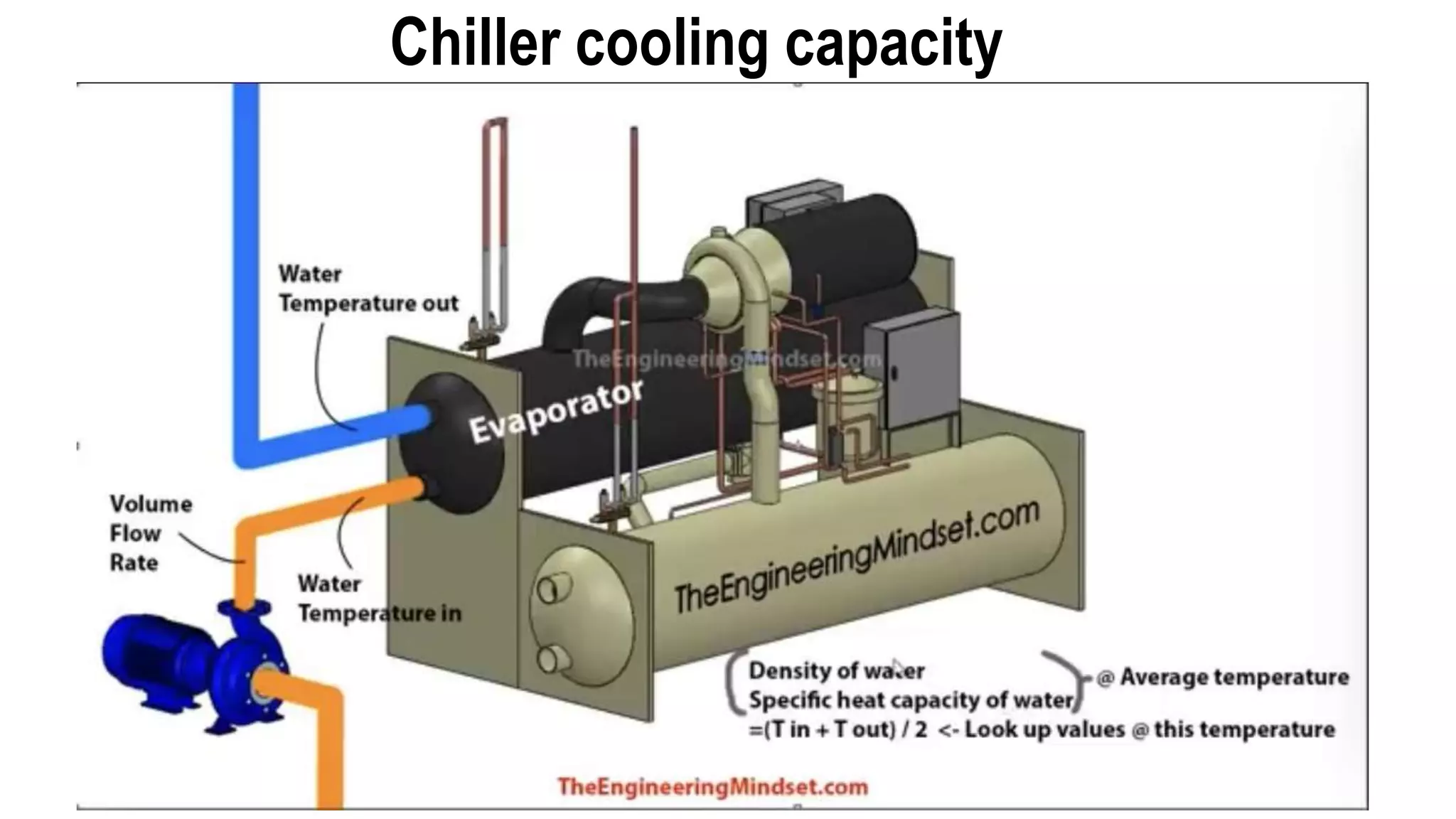

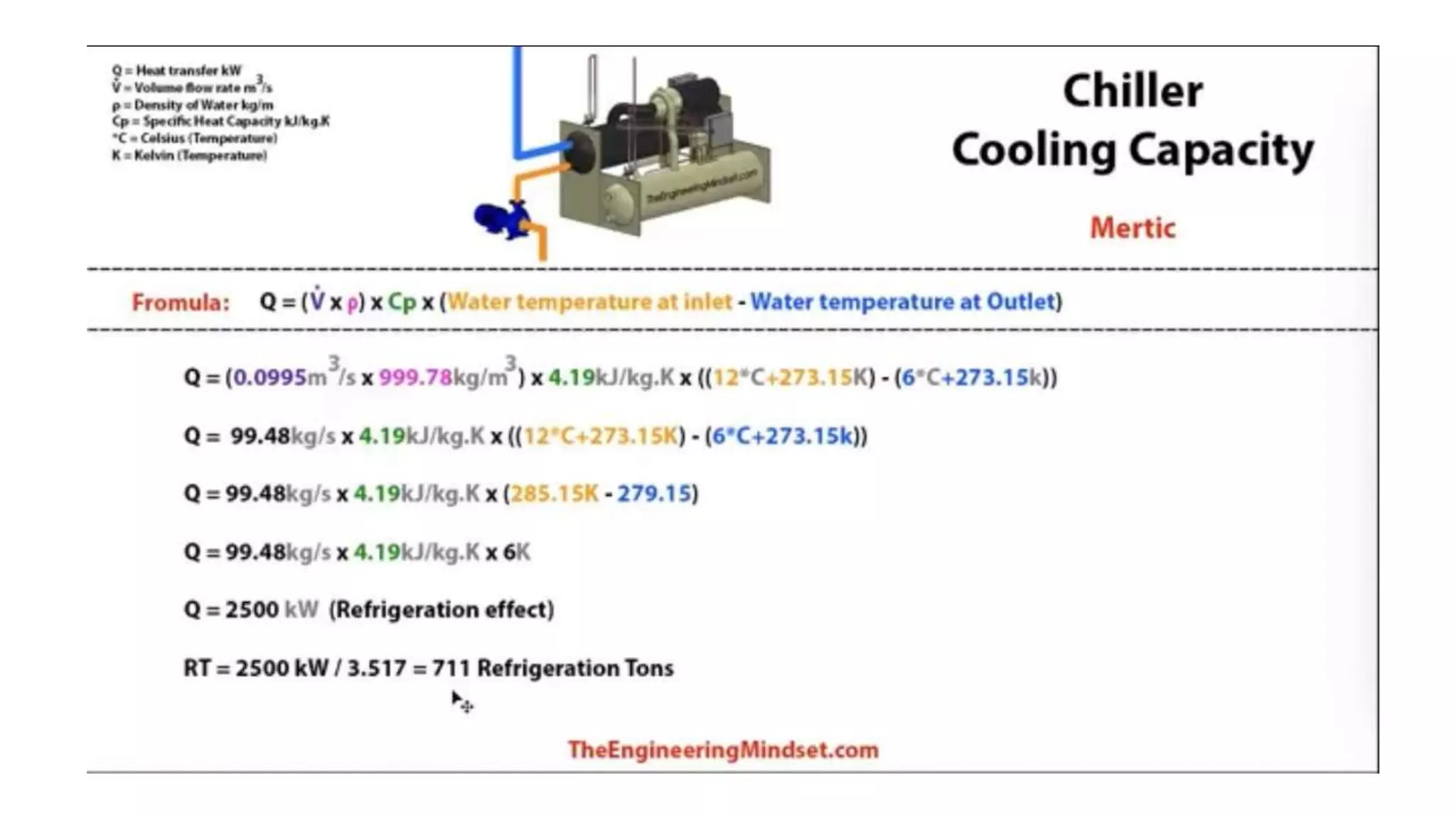

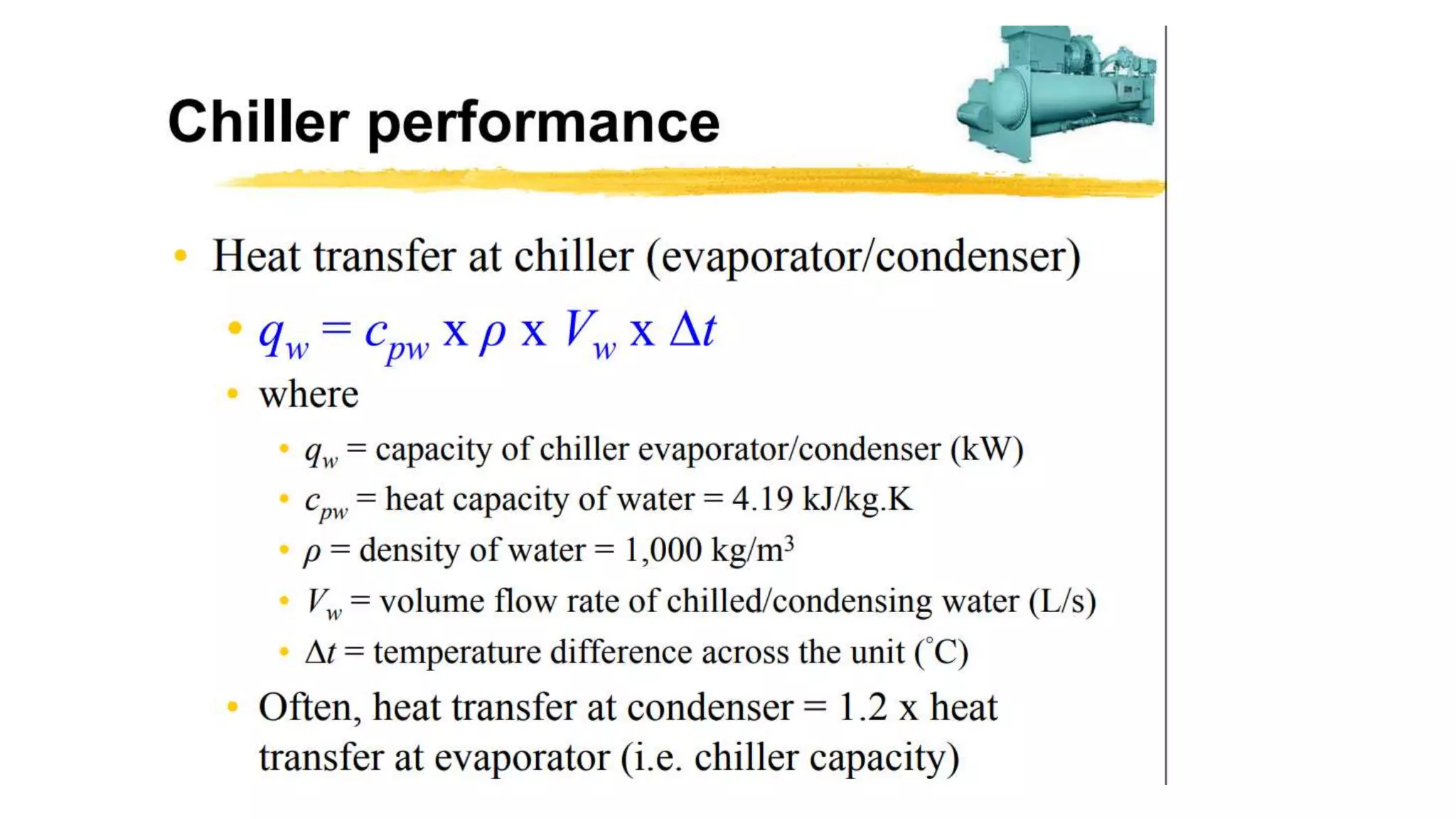

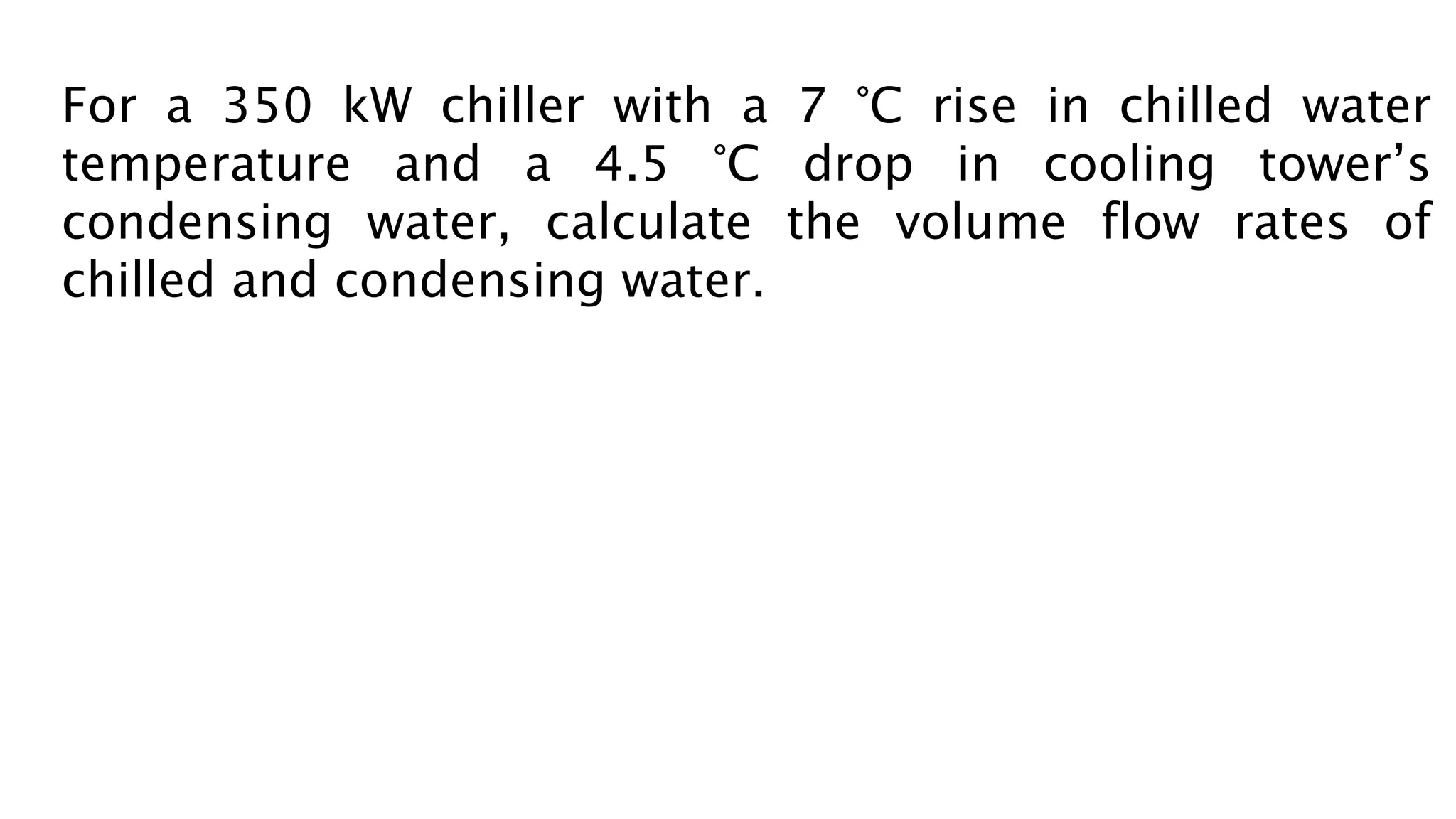

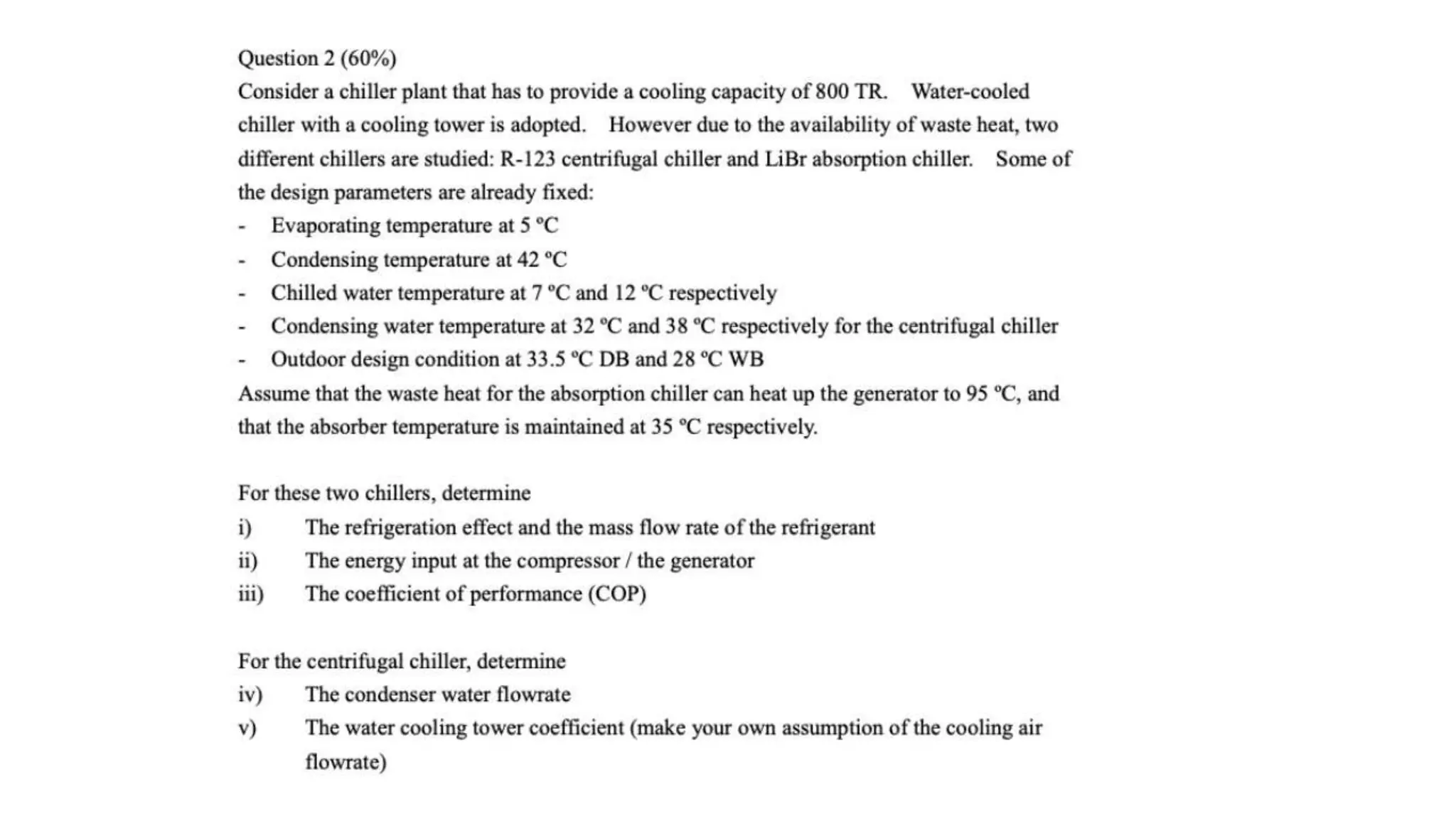

A chiller is a machine that produces chilled water for air conditioning. There are two main types based on refrigeration cycle: vapor compression and absorption. There are also two types based on condensation process: air-cooled and water-cooled. The key components of a chiller system include the chiller (with evaporator and condenser cylinders), compressors, pumps, cooling towers, and load terminals. The chiller circulates chilled water to air handlers to transfer heat from the air to the water, which then returns to the evaporator to transfer heat to refrigerant before being compressed and releasing heat in the condenser. Performance is measured in tons of refrigeration, kW/ton efficiency rating, COP, and