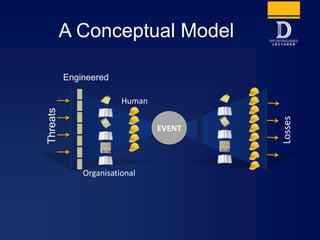

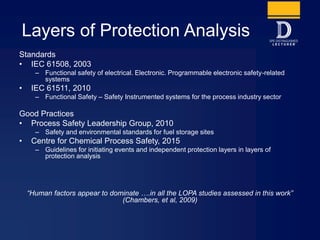

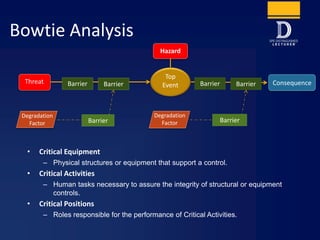

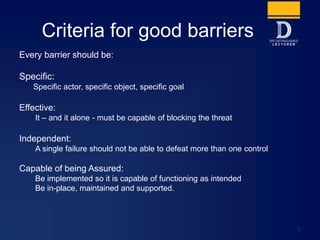

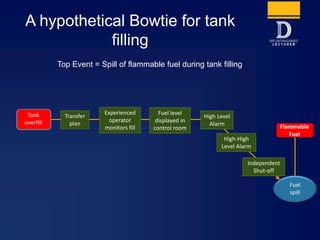

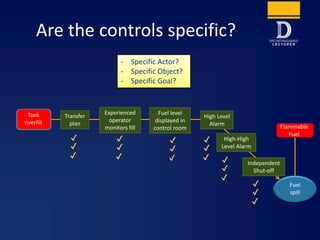

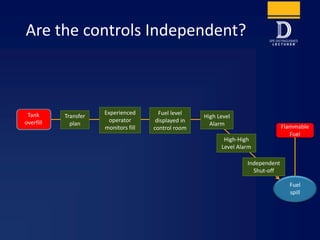

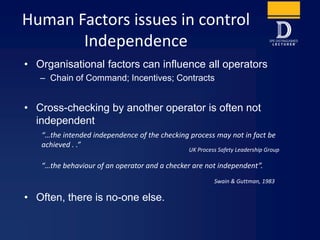

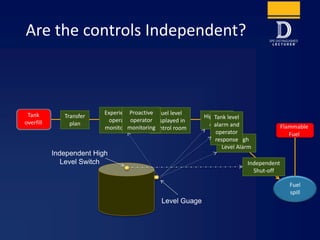

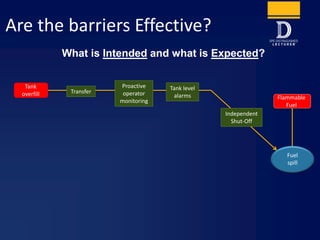

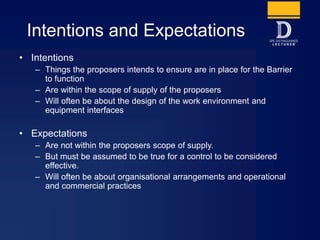

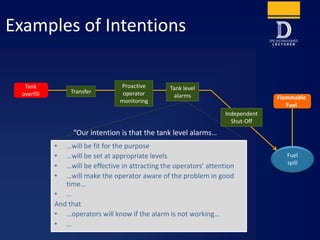

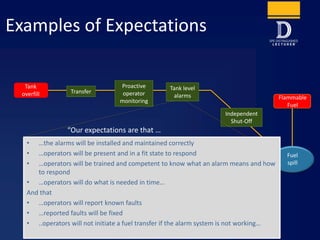

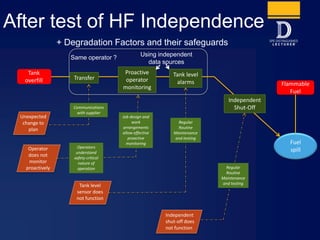

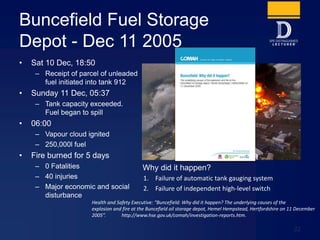

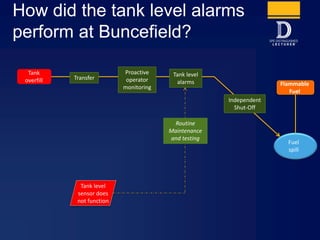

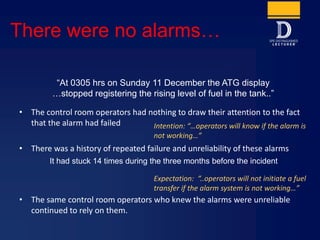

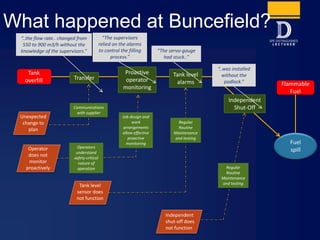

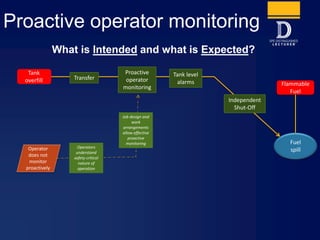

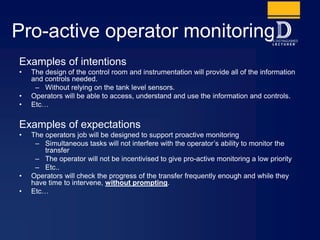

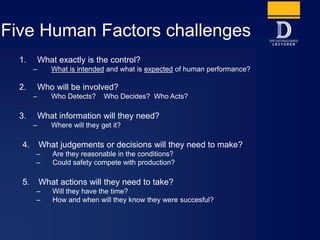

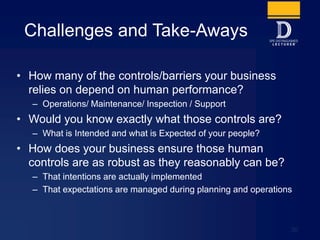

The document discusses the importance of human factors in barrier thinking within safety management strategies, focusing on how human performance affects the effectiveness and independence of safety controls. It emphasizes the need for clear intentions and expectations in human performance and discusses real-world challenges illustrated by the Buncefield fuel storage incident. The document outlines five key challenges to enhance the robustness of human controls in safety operations.