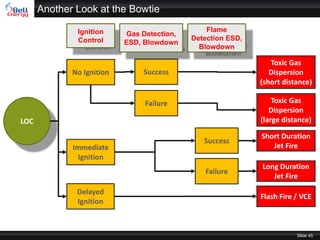

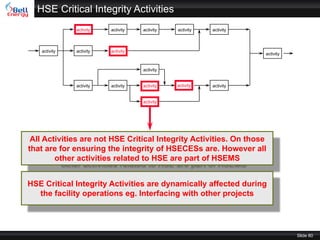

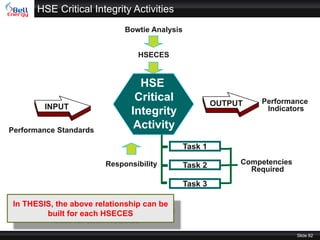

The document explains the concept of bowties, which visually represent the relationship between the causes and consequences of major accident hazards, particularly in the oil and gas industry. It describes the essential components such as threats, top events, and barriers, as well as the importance of operationalizing these systems for effective risk management. Additionally, the document outlines common terminologies, advantages, and potential disadvantages associated with bowties.