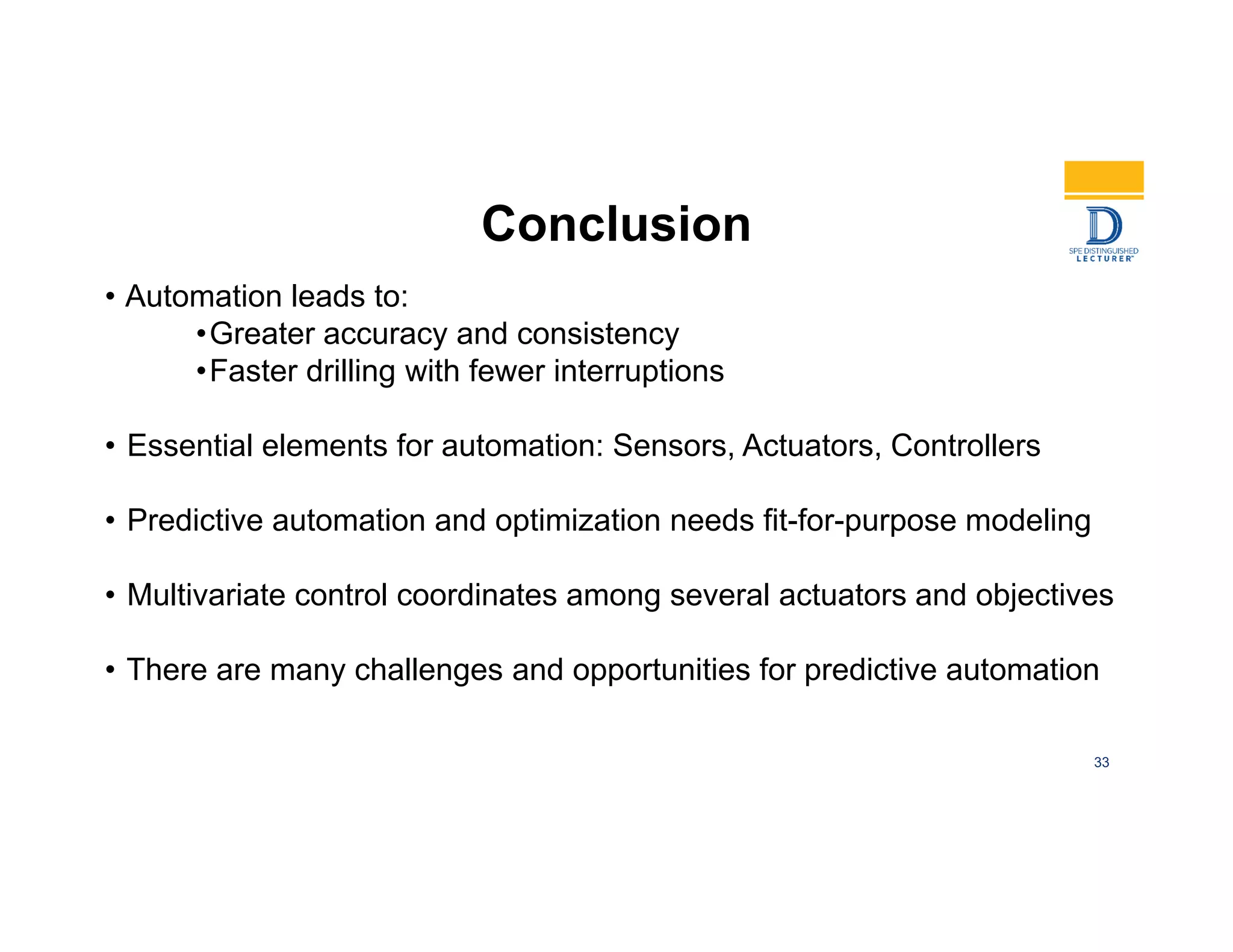

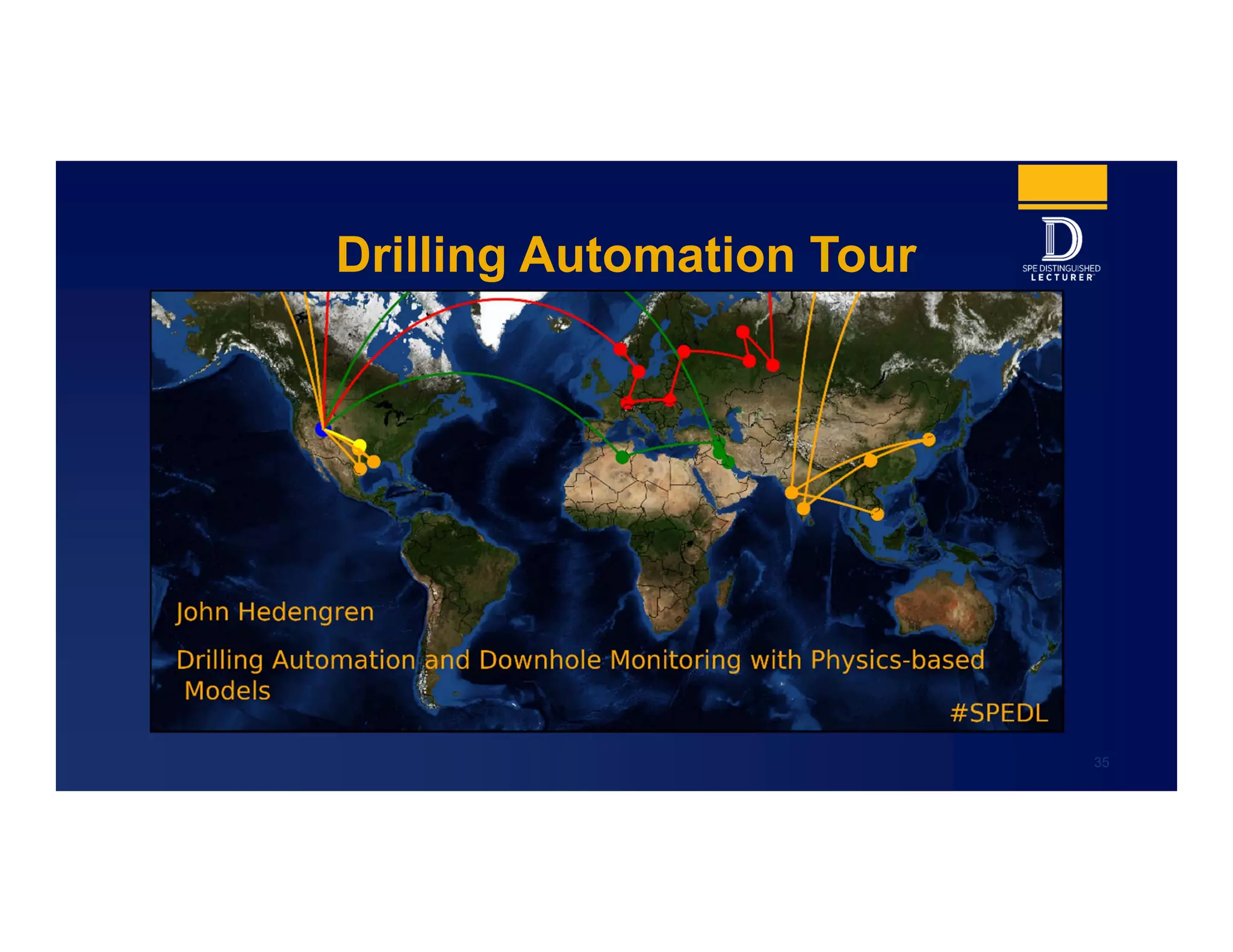

Primary funding for the Society of Petroleum Engineers Distinguished Lecturer Program is provided through member donations to the SPE Foundation and a contribution from Offshore Europe. Additional support comes from AIME. The program offers lectures from industry professionals on various topics, and is grateful to companies that allow their employees to participate as lecturers.