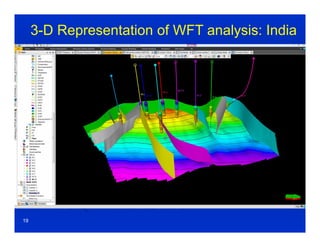

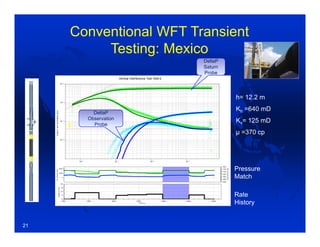

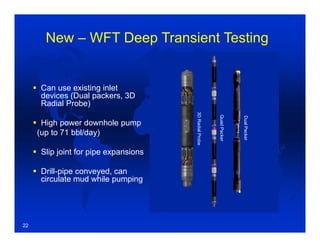

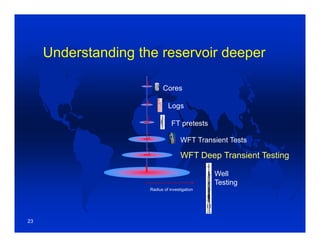

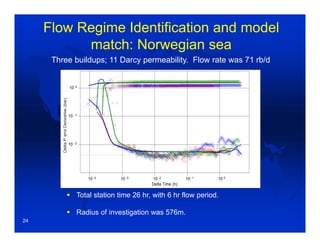

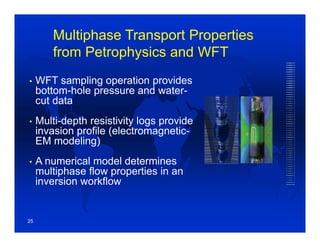

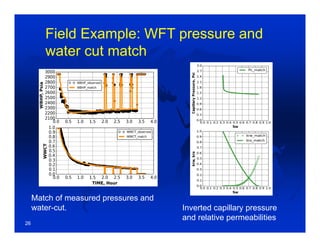

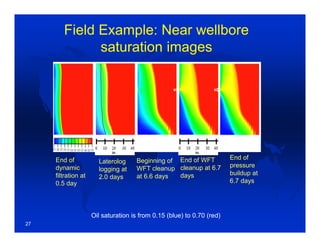

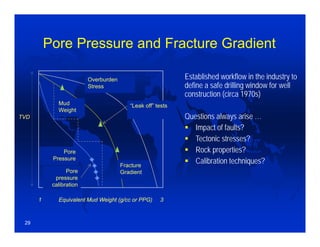

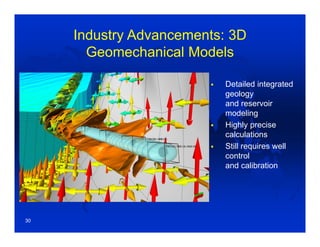

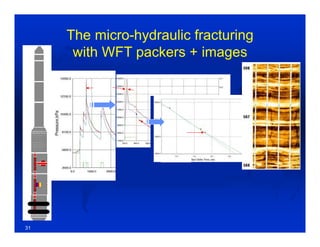

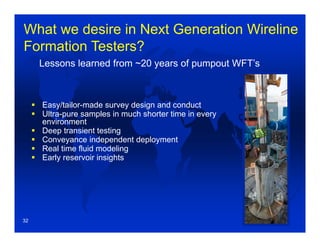

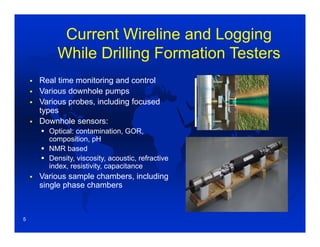

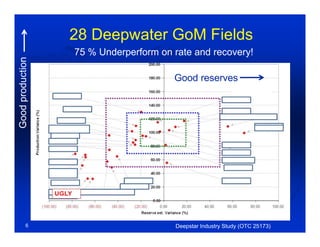

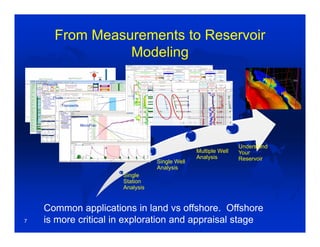

The document summarizes a presentation on using wireline formation testing (WFT) to characterize reservoirs and reduce uncertainties. It discusses how WFT can be used to measure pressures, sample and analyze downhole fluids, conduct transient tests, and test in-situ stresses. The results from these WFT analyses can be integrated into reservoir modeling workflows and help understand properties like permeability, fluid contacts, and the safe drilling window. Advanced sensors and improved transient testing capabilities in new generation WFT tools are providing more downhole data to reduce risks in reservoir evaluation.

![10

-2

10

-1

10

0

10

1

10

2

10

-2

10

-1

10

0

Time [hrs]

Contamination

5% contamination

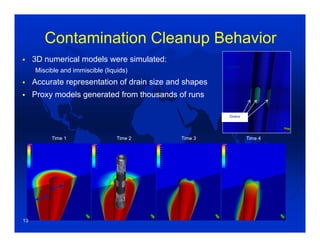

Saturn 3D Radial Probe

XLD Probe

Dual Packers

3D Radial Probe

Tool Cleanup

time

(5%)

[hrs]

3D Radial Probe 0.71

Extra Large

Dimension Probe

9.10

Dual Packers 1.00

3 Dimensional

Radial Probe

Probe Dual Packers

Contamination Cleanup Behaviour

Slope = -

5/12

Slope

= -2/3

1414](https://image.slidesharecdn.com/cosanayan-190821142548/85/Cosan-Ayan-14-320.jpg)