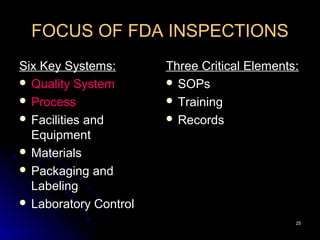

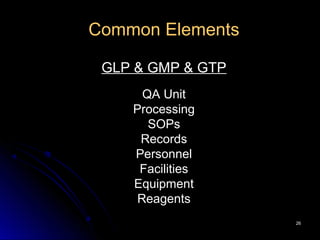

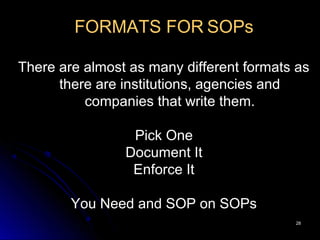

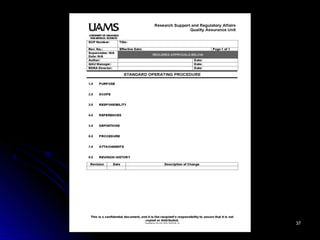

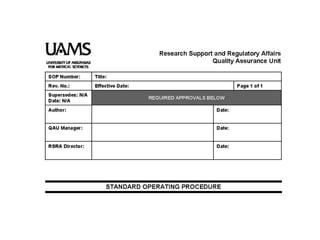

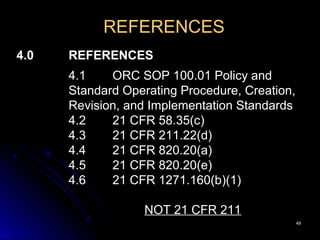

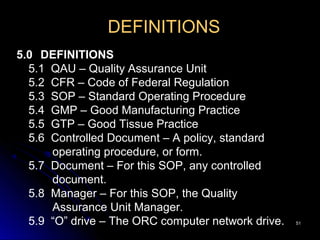

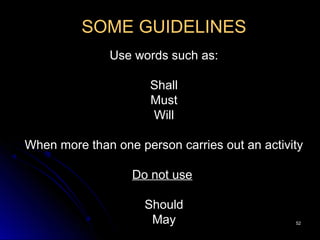

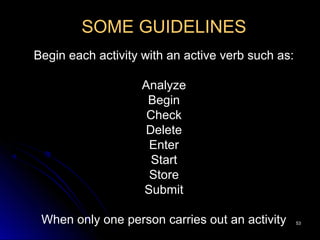

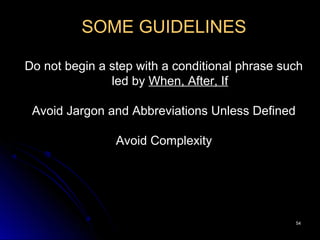

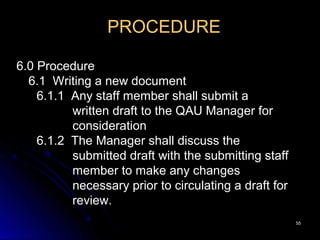

The document outlines the purpose and importance of standard operating procedures (SOPs), detailing their role in ensuring safety, regulatory compliance, and consistent training. It explains various formats for SOPs, the process of writing them, and the necessary components such as purpose, scope, and responsibilities. Additionally, it emphasizes the regulatory requirements associated with SOPs and provides guidelines for creating effective SOPs within organizations.