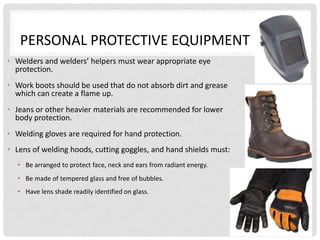

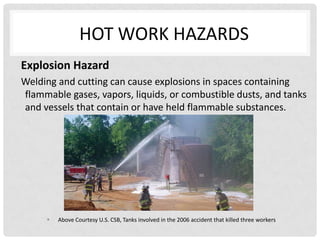

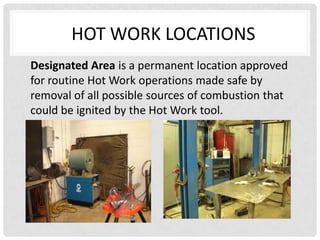

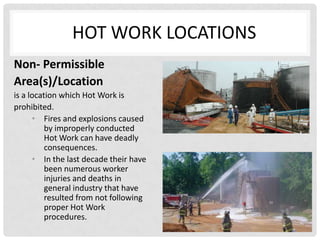

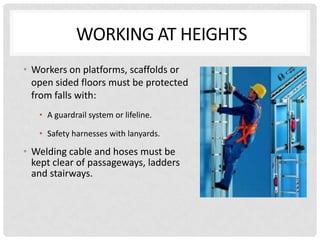

The document provides guidance on preparing for and conducting hot work safely. It discusses personal protective equipment, fire prevention measures, identifying hazards of hot work like sparks and explosions, and permissible versus non-permissible locations for hot work. Designated areas are approved, permanent locations where hot work can be done routinely. Controlled areas require a hot work permit after combustibles are removed or protected. Confined spaces require venting, purging of gases, and keeping cylinders and equipment outside the space.