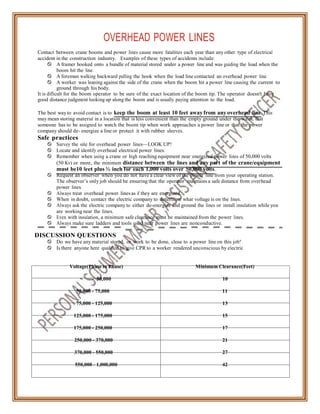

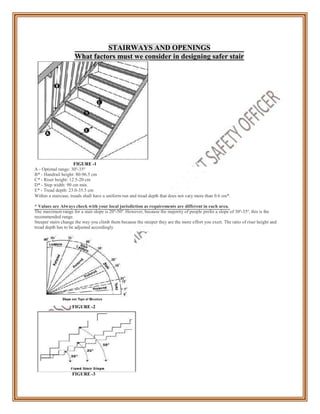

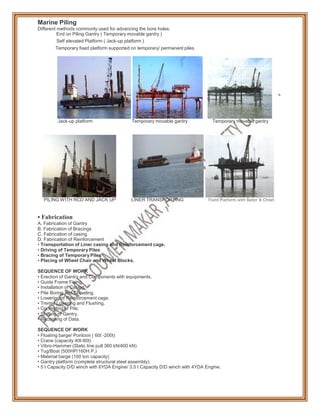

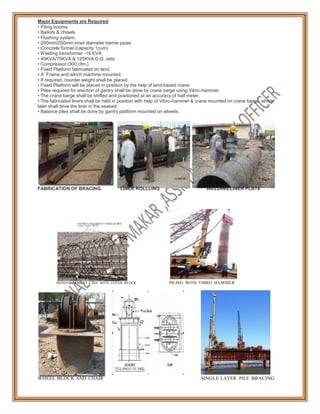

This handbook serves as a comprehensive safety and health resource for marine construction teams, detailing essential safety precautions and practices. It covers a wide array of topics, including cold-related safety, driver safety, hearing protection, electrical hazards, and proper equipment usage. The aim is to inform team members about their responsibilities and promote a safer working environment through awareness and training.