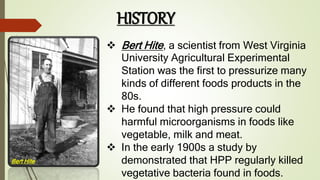

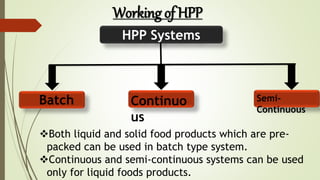

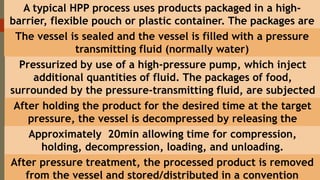

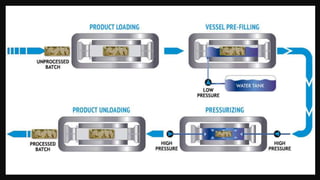

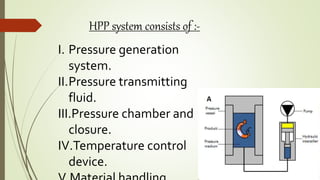

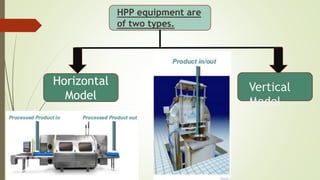

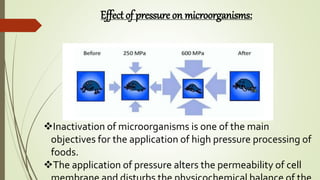

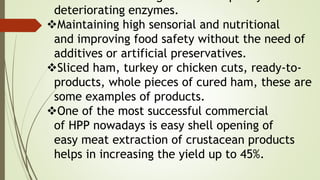

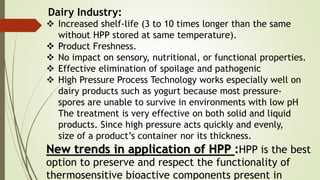

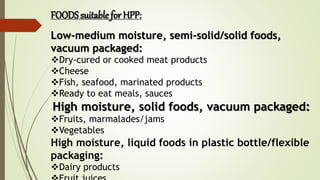

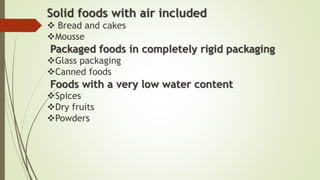

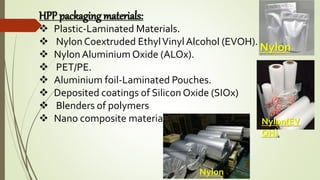

High Pressure Processing (HPP) is an emerging food preservation technique that uses very high pressures to extend shelf life while retaining food quality, without heat treatment. The process, developed from research in the 1980s, effectively eliminates harmful microorganisms and enzymes, making it suitable for a wide range of food products, particularly in the meat, dairy, and fruit industries. Key considerations for HPP include pressure equipment, suitable packaging, and the impact of high pressure on food texture, color, and nutritional value.