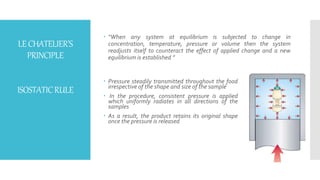

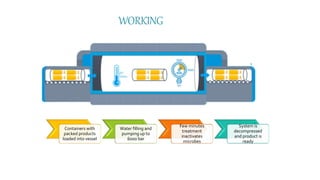

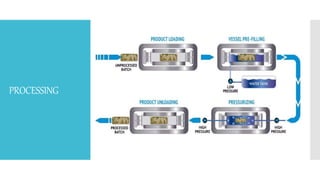

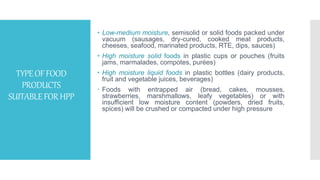

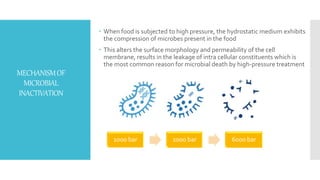

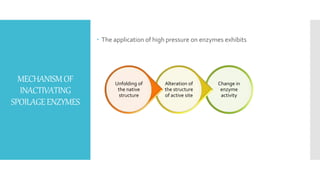

High Pressure Processing (HPP) is a non-thermal food preservation technique that uses hydrostatic pressure to inactivate microorganisms and enzymes, thus extending shelf life significantly, sometimes up to ten times compared to untreated products. Initially commercialized in Japan in the early 1990s, HPP is applicable to a variety of food products including meats, dairy, and fruits, requiring specific air-tight packaging that can withstand pressure changes. The method effectively maintains the sensory and nutritional qualities of food while improving its safety.