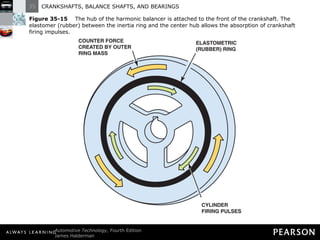

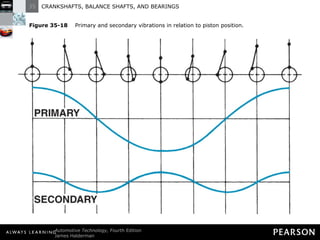

This document discusses crankshafts, balance shafts, and engine bearings. It describes the purpose and function of crankshafts, how they are constructed and balanced using counterweights. It also discusses the different types of crankshaft designs used in various engine configurations like V6, V8, inline 4 and 6 cylinder engines. Balance shafts are introduced as a way to reduce engine vibration.