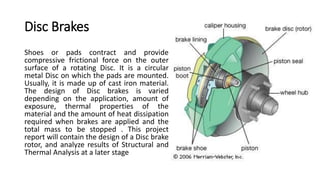

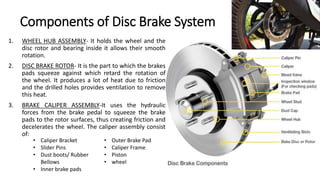

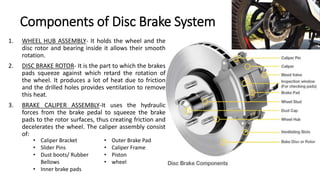

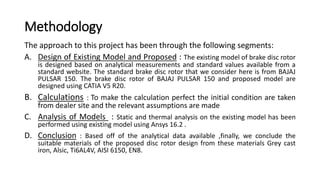

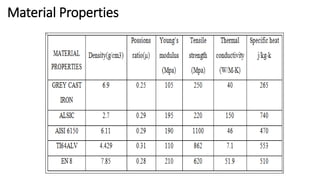

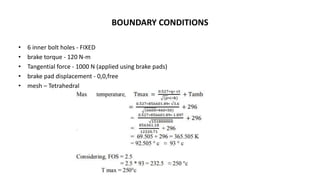

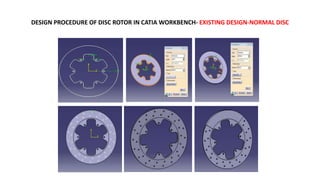

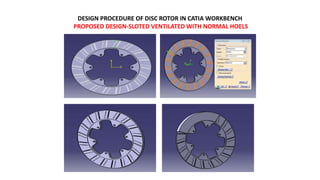

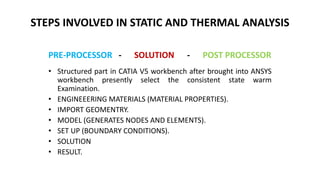

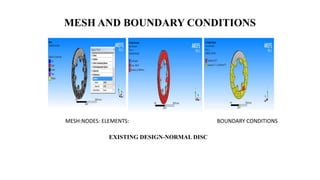

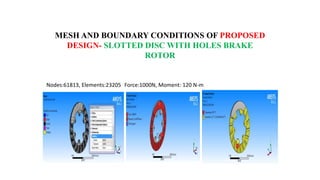

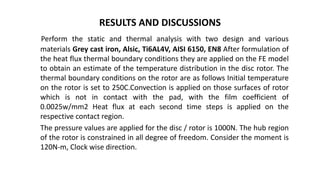

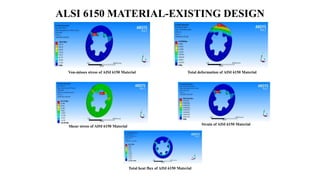

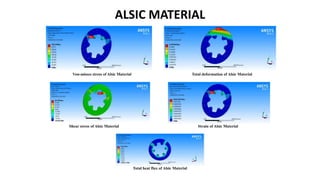

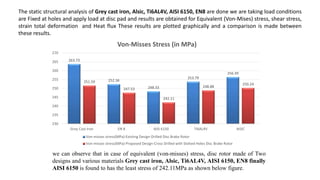

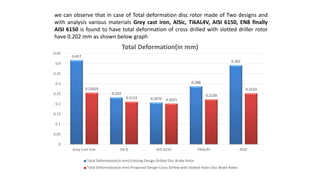

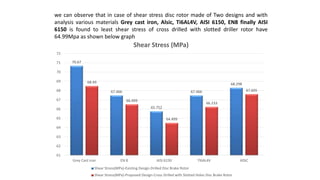

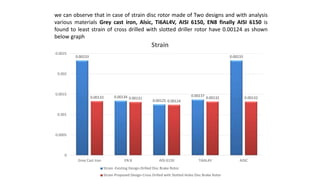

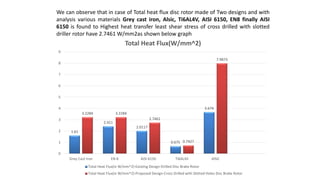

The document discusses the design, analysis, and optimization of a disc brake rotor for a Bajaj Pulsar 150 motorcycle using finite element analysis. It summarizes the existing ventilated disc brake rotor design and proposes a new slotted design with holes. Both designs are modeled in CATIA and analyzed in ANSYS for static structural stresses and transient thermal performance using various materials. The analysis aims to determine the material that provides the best performance for the proposed design based on von Mises stresses, heat dissipation, and deformation.