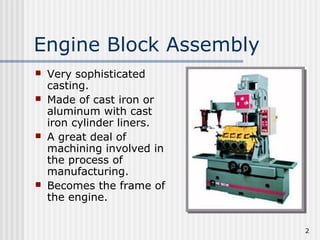

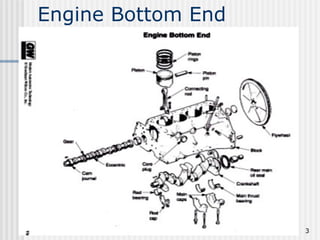

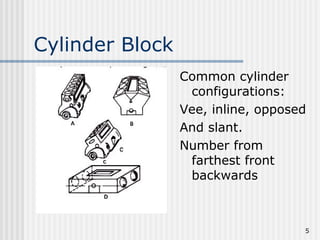

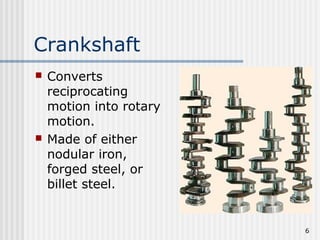

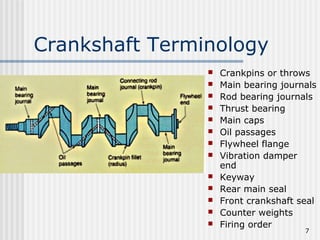

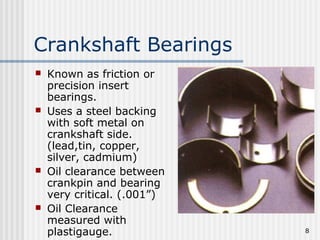

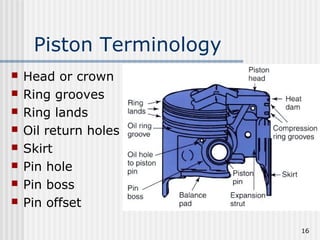

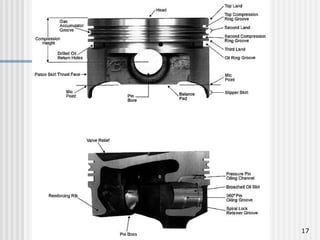

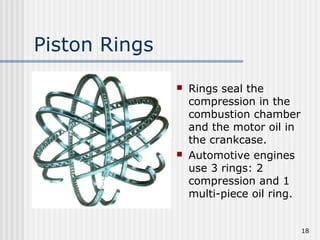

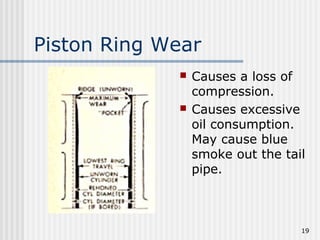

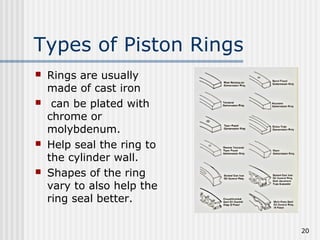

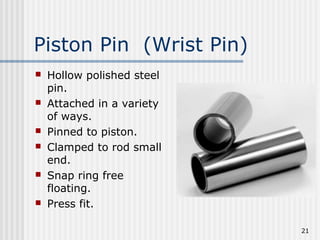

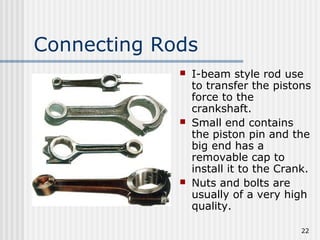

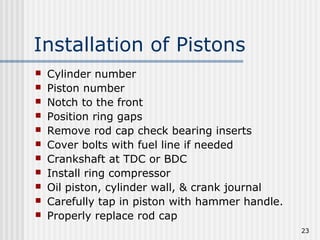

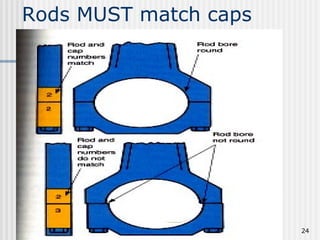

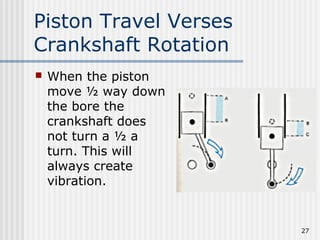

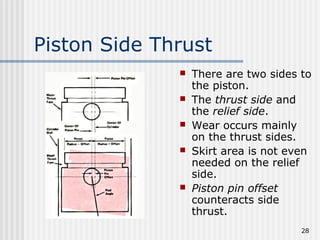

The document discusses the key components that make up the bottom end of an engine, including the engine block, crankshaft, connecting rods, pistons, rings, and bearings. It describes the materials, functions, and terminology associated with each part. The crankshaft converts the reciprocating motion of the pistons into rotational motion to power the vehicle. Pistons harness the energy of combustion and transfer force to the crankshaft via connecting rods. Precise clearances and alignments are needed for proper engine operation and longevity.