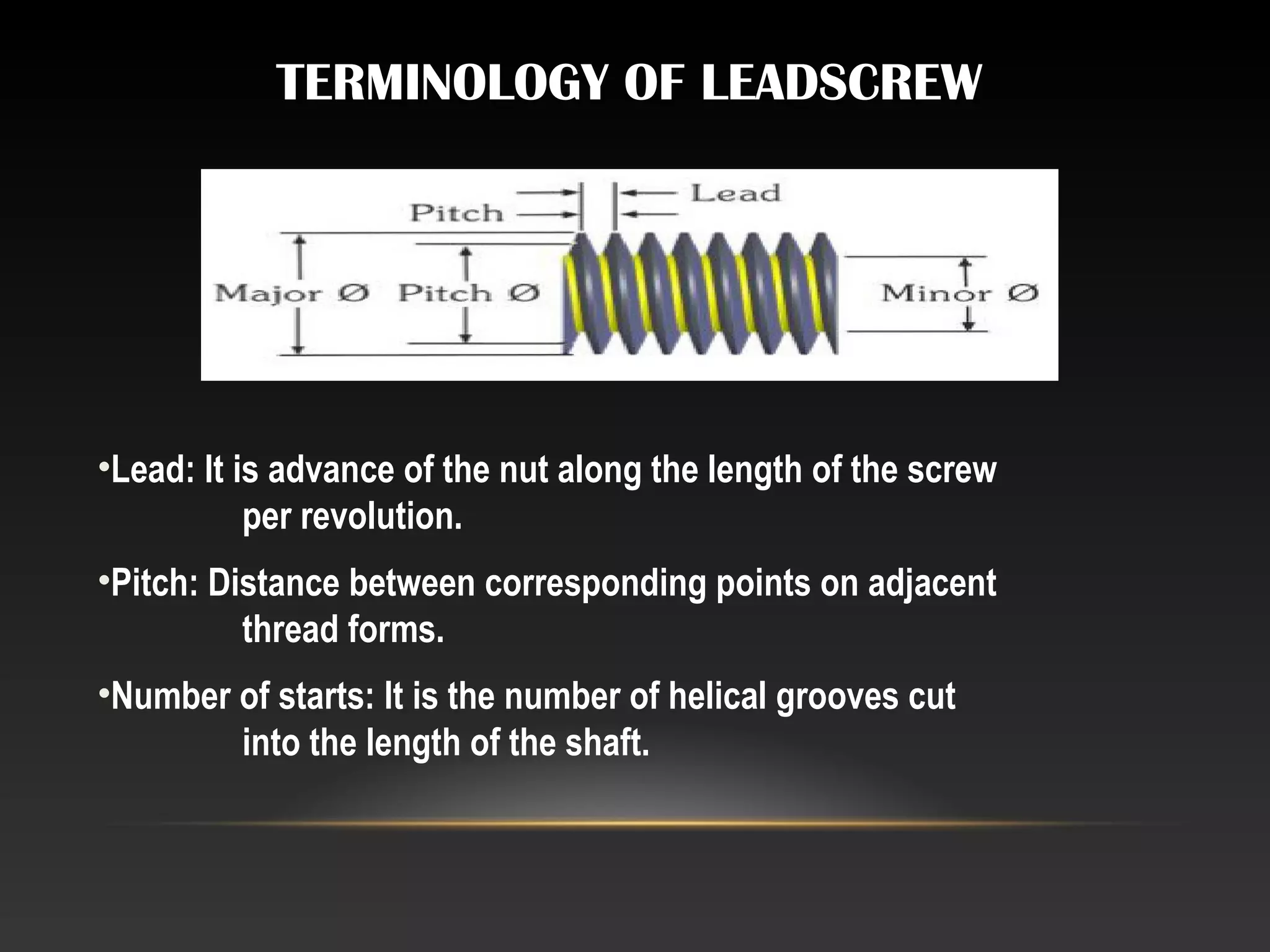

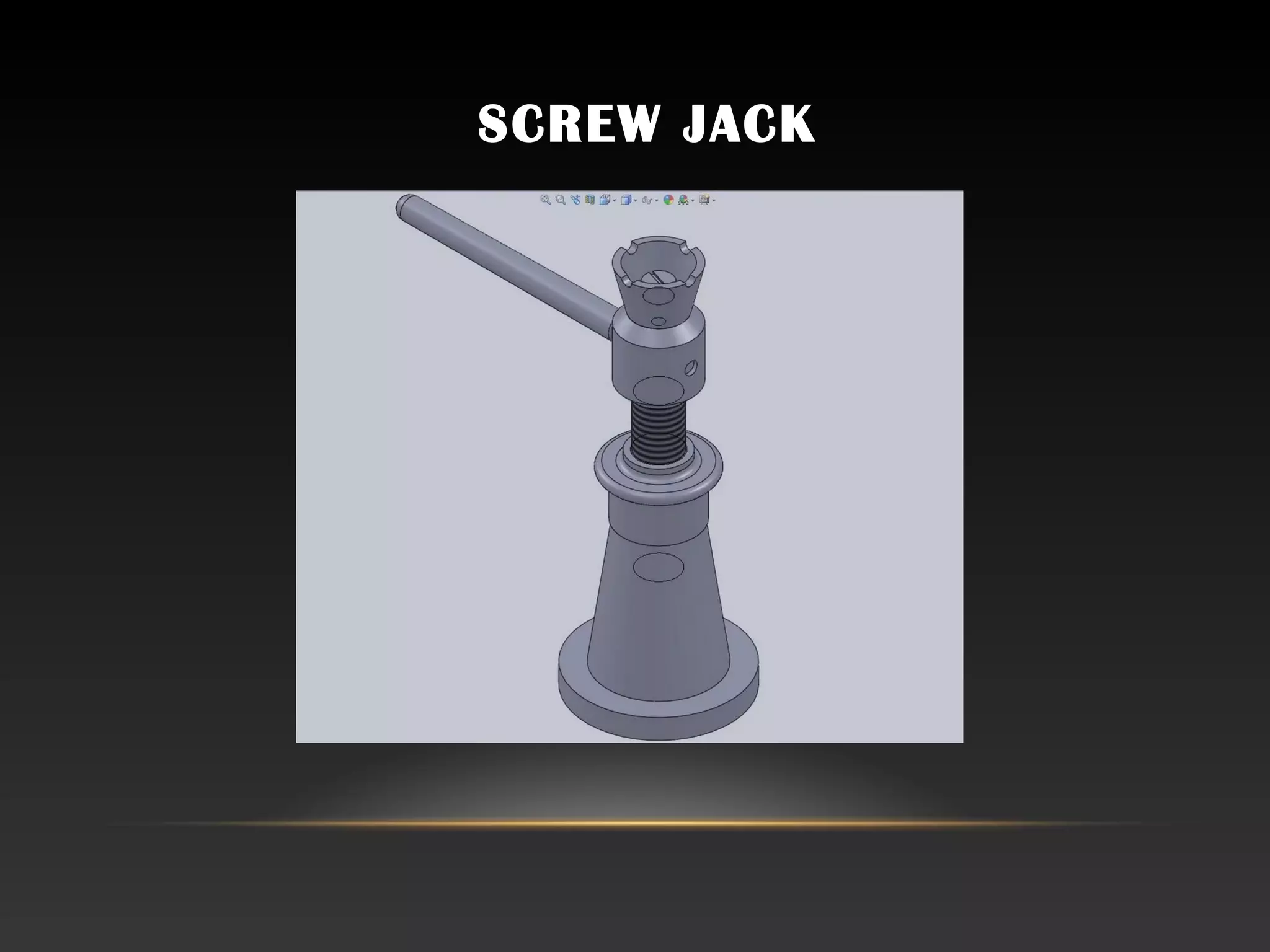

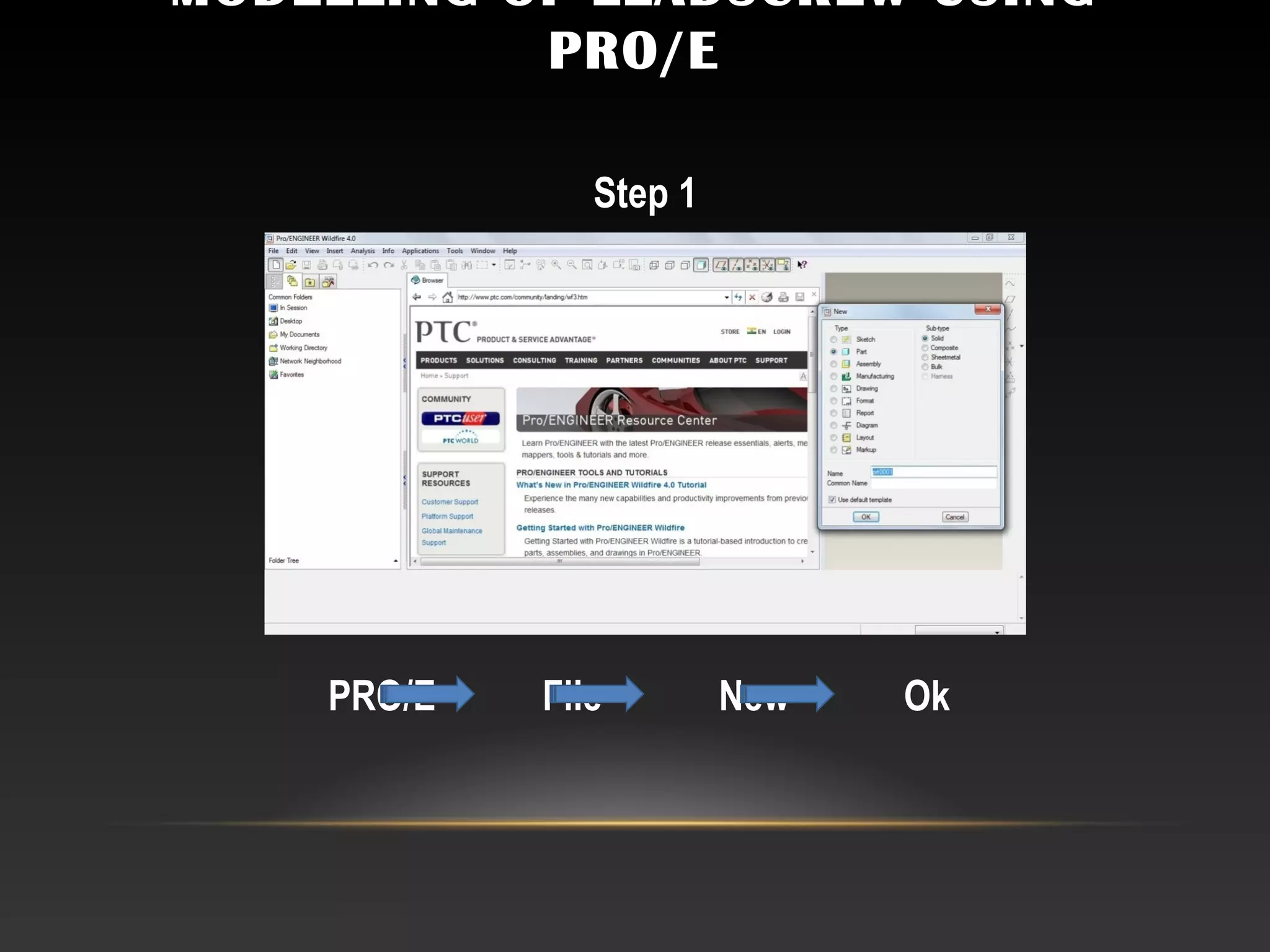

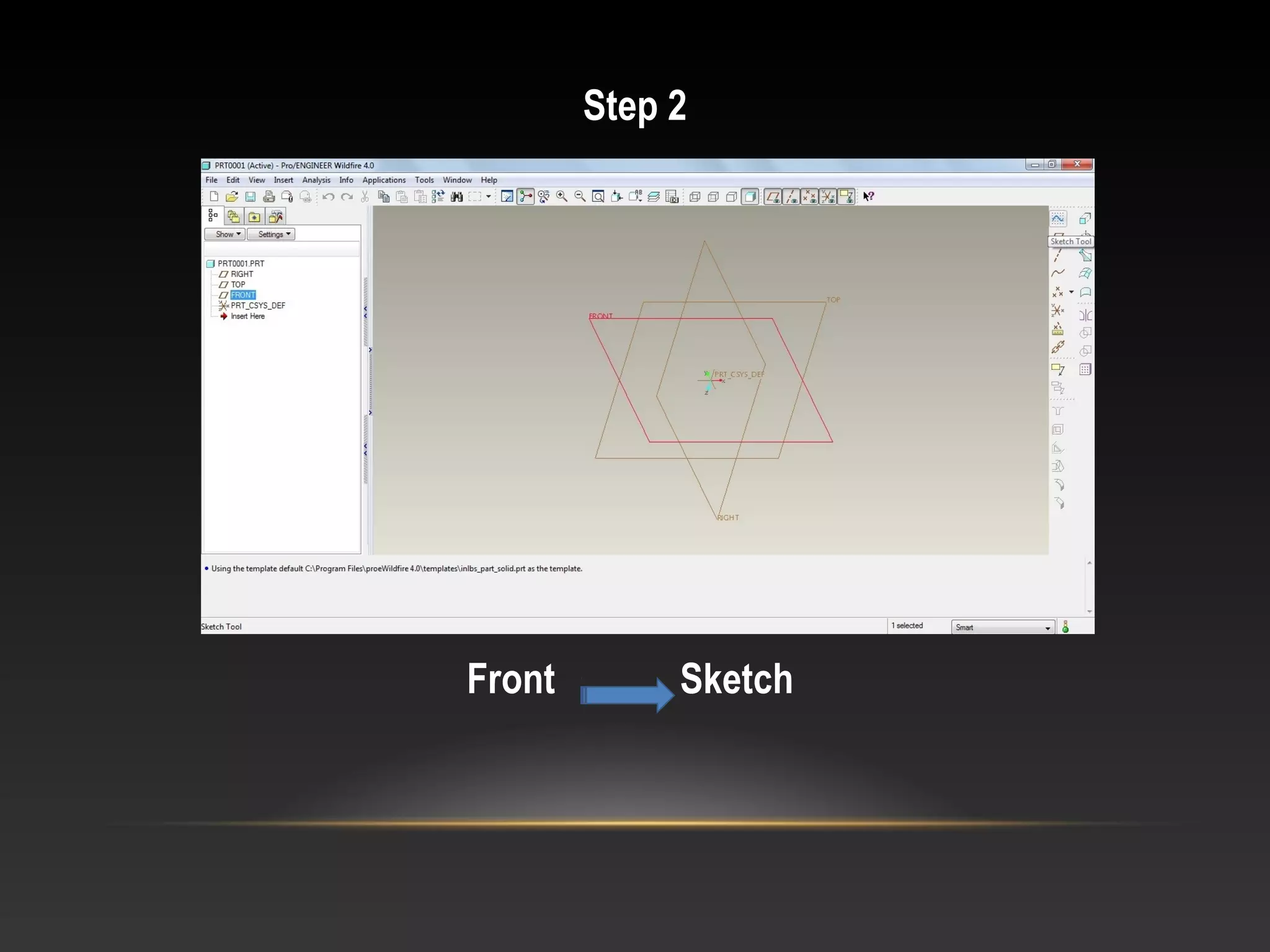

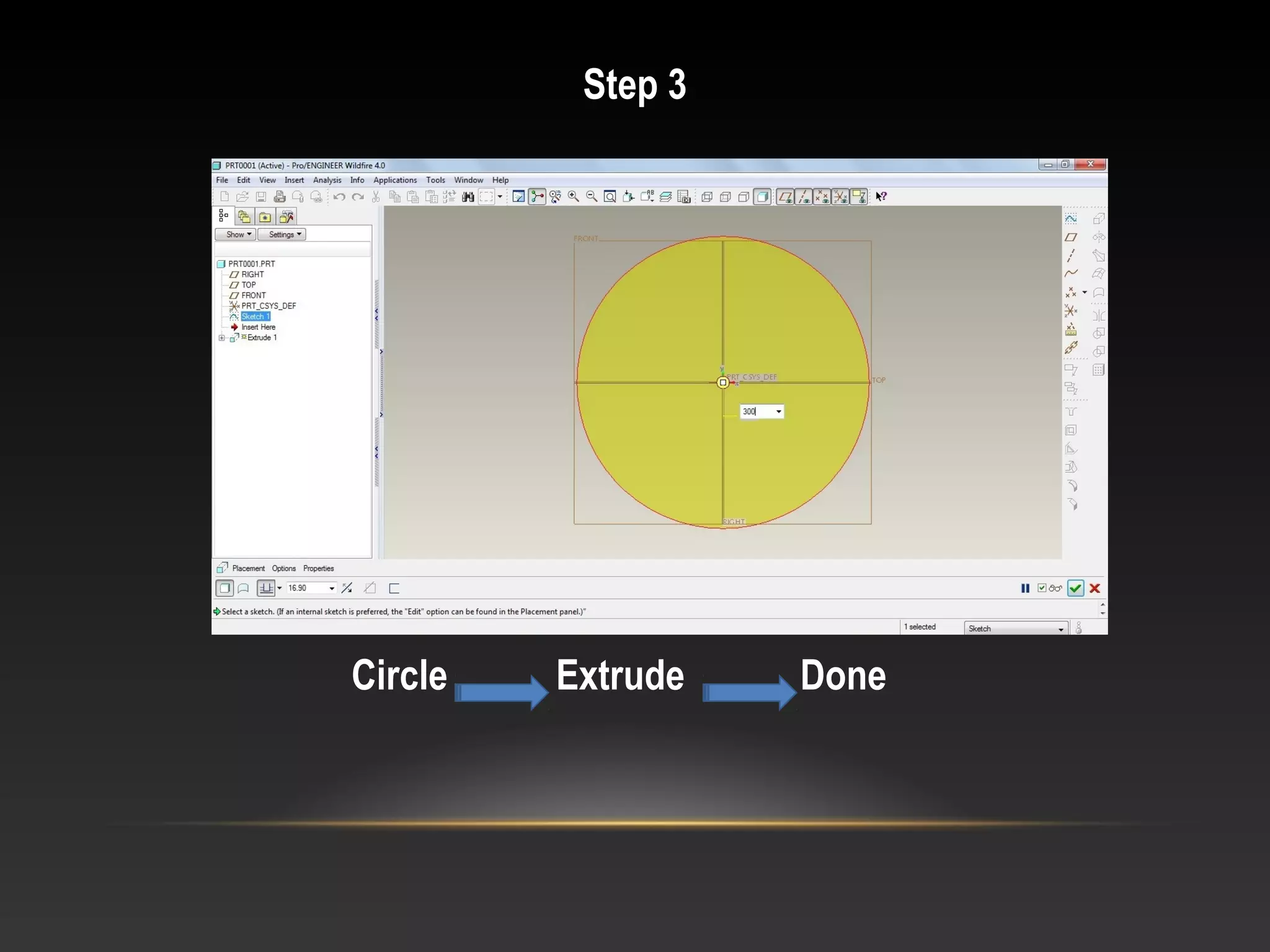

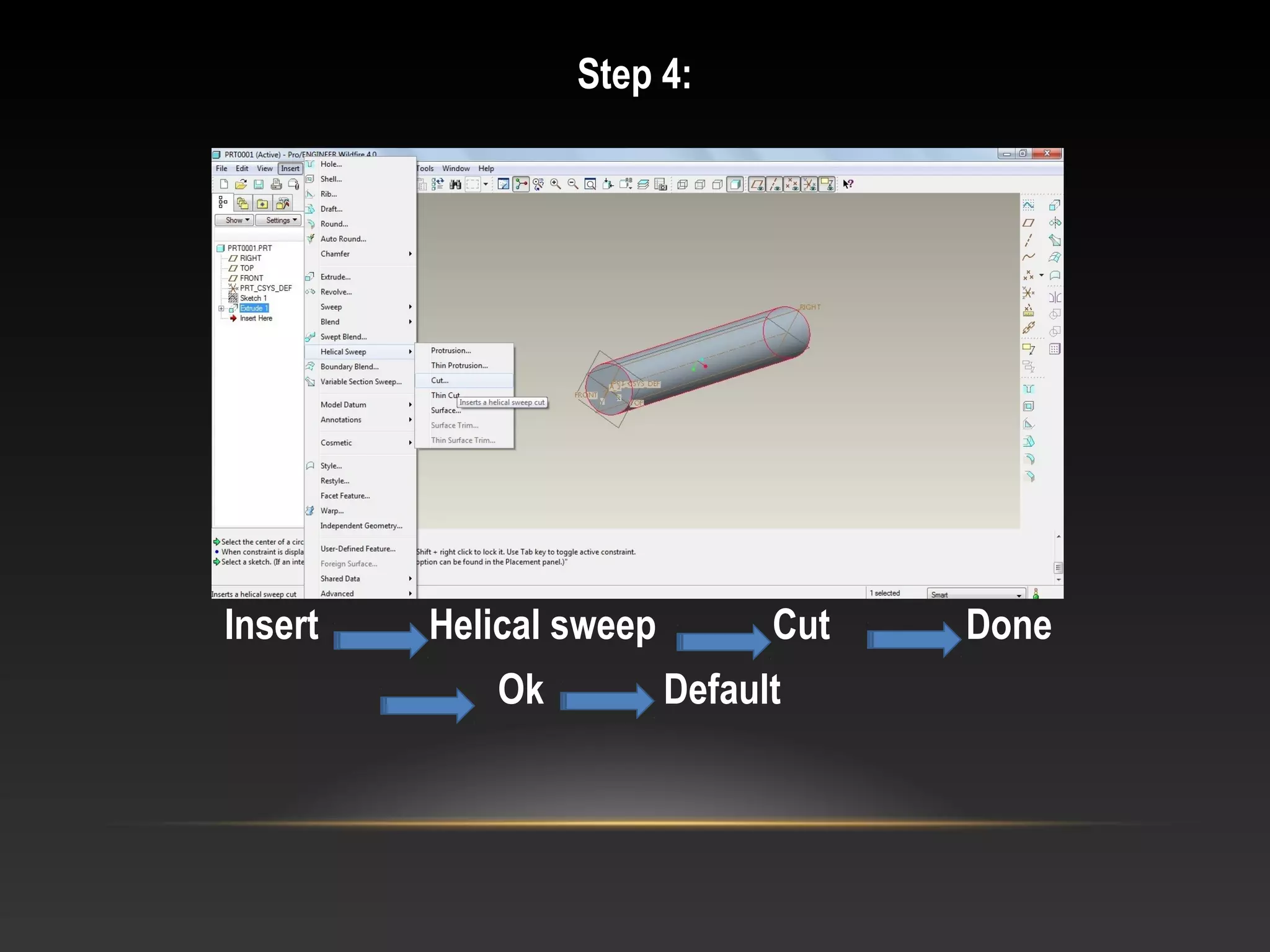

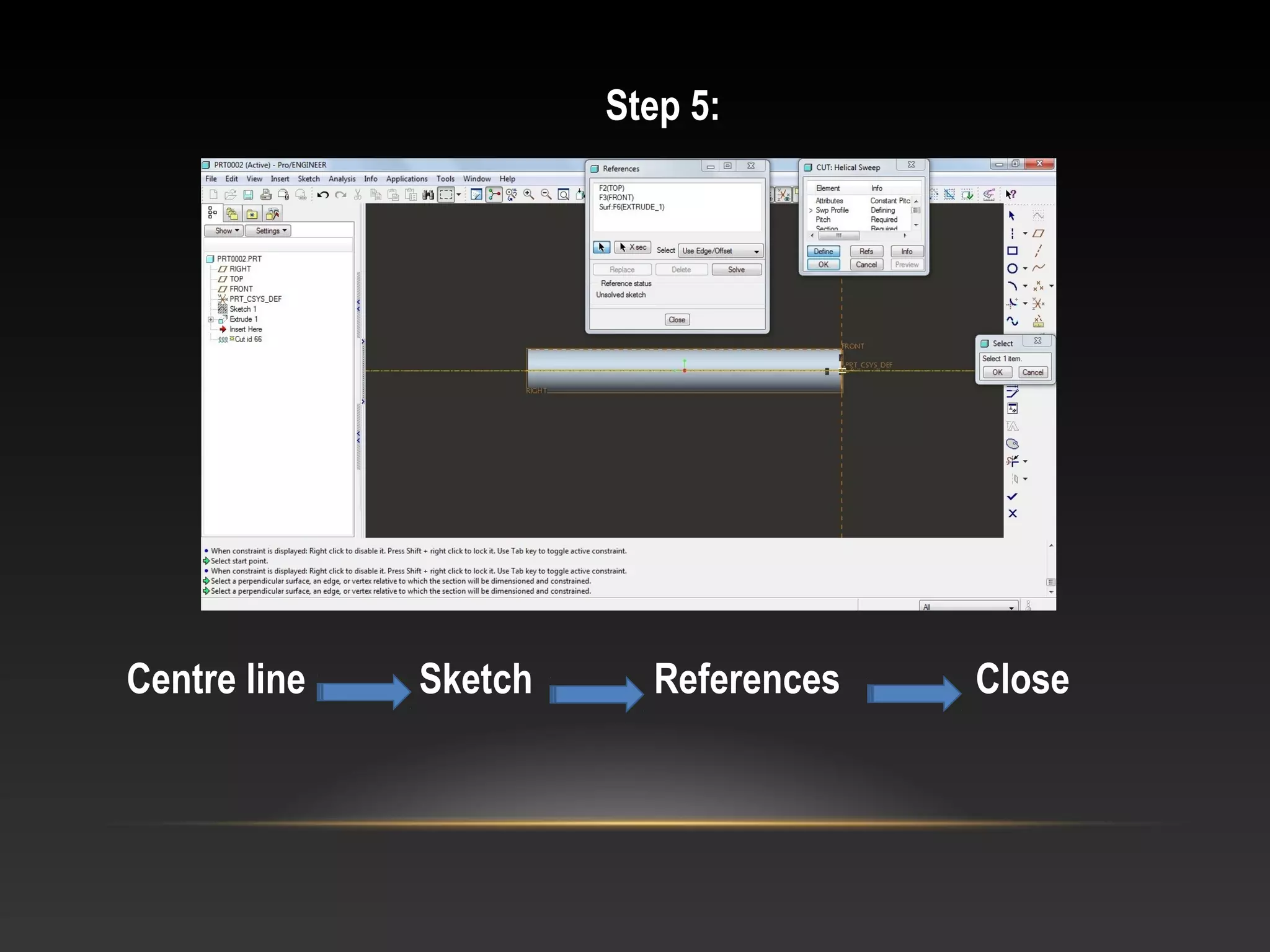

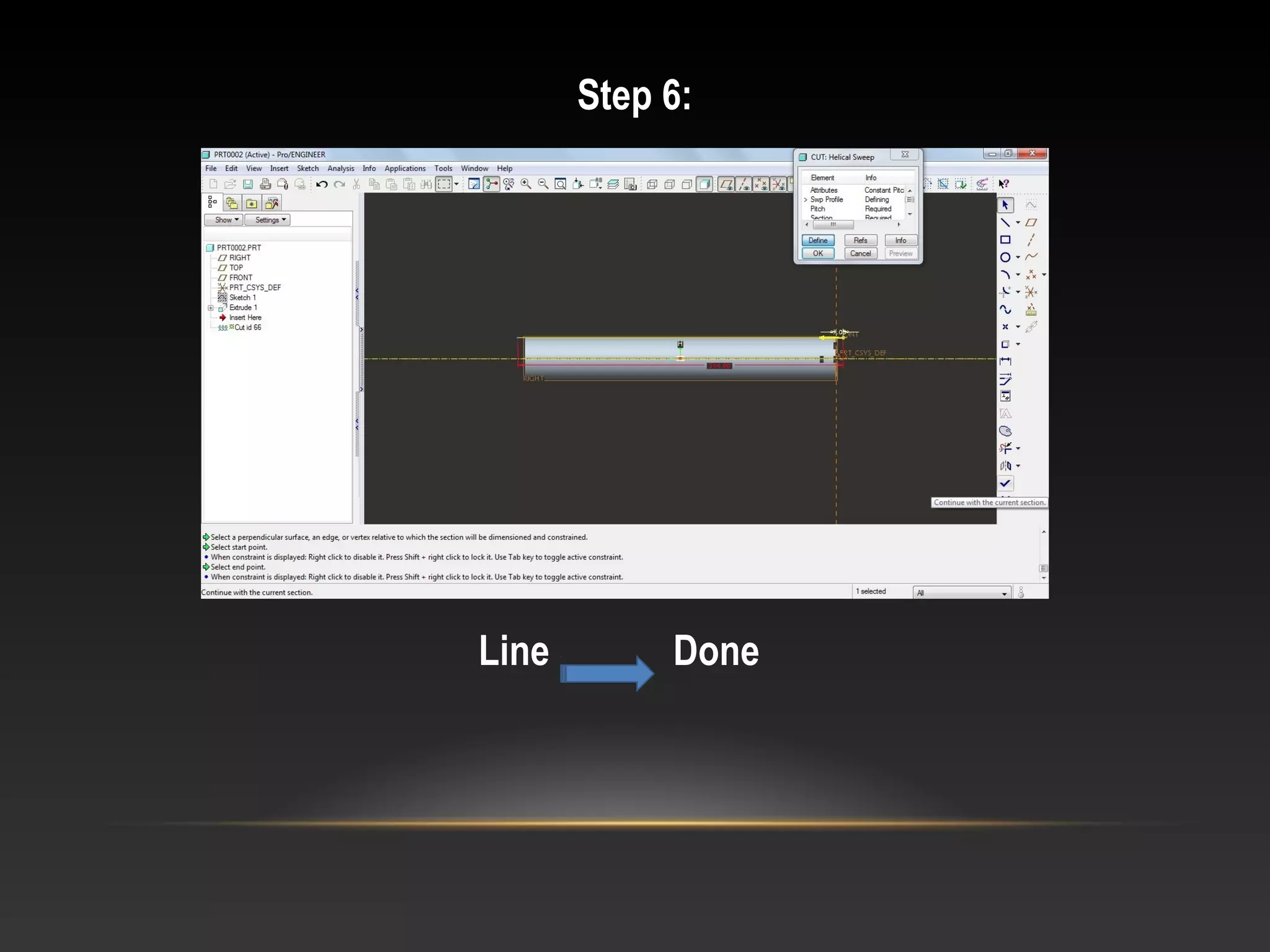

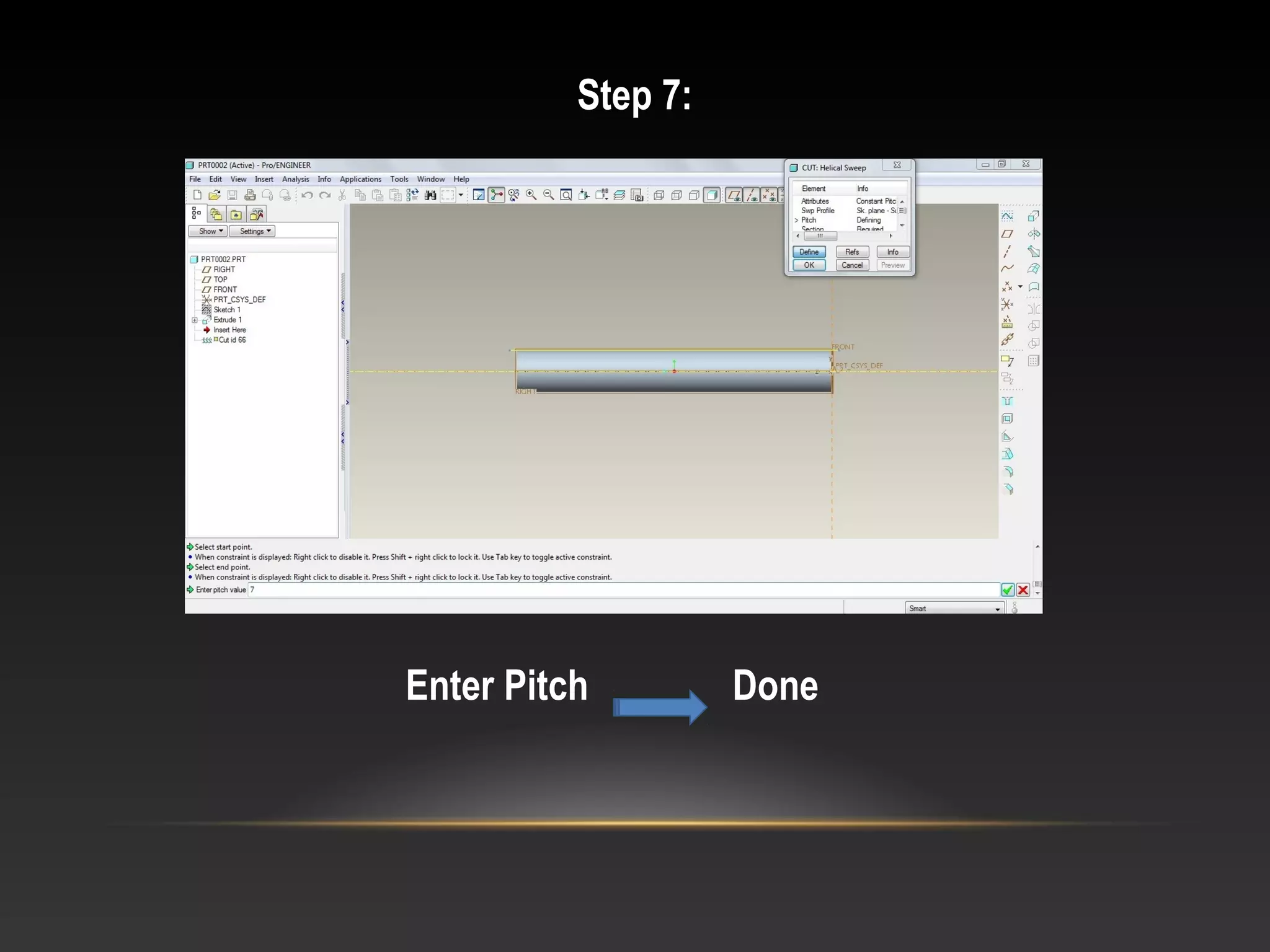

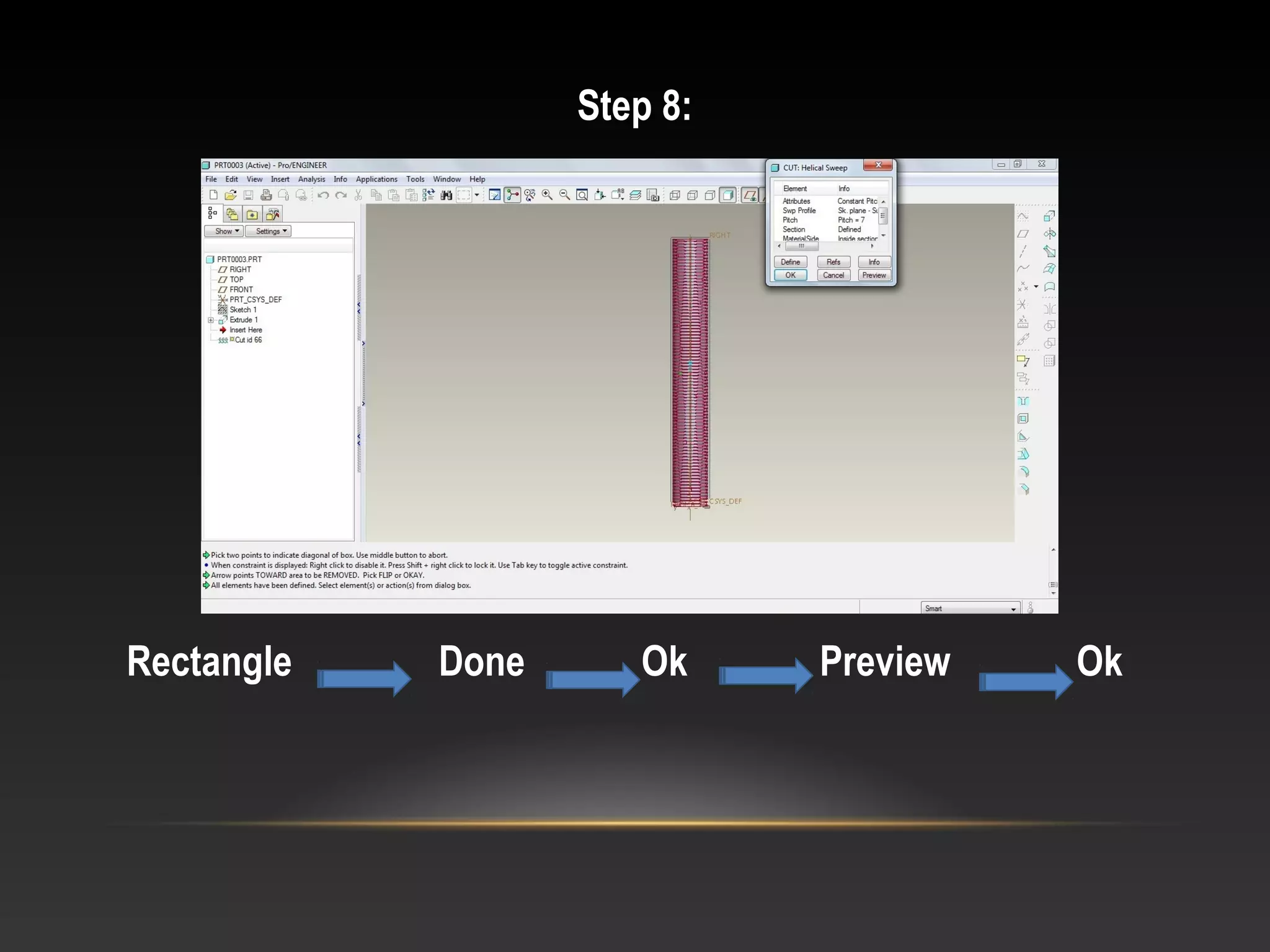

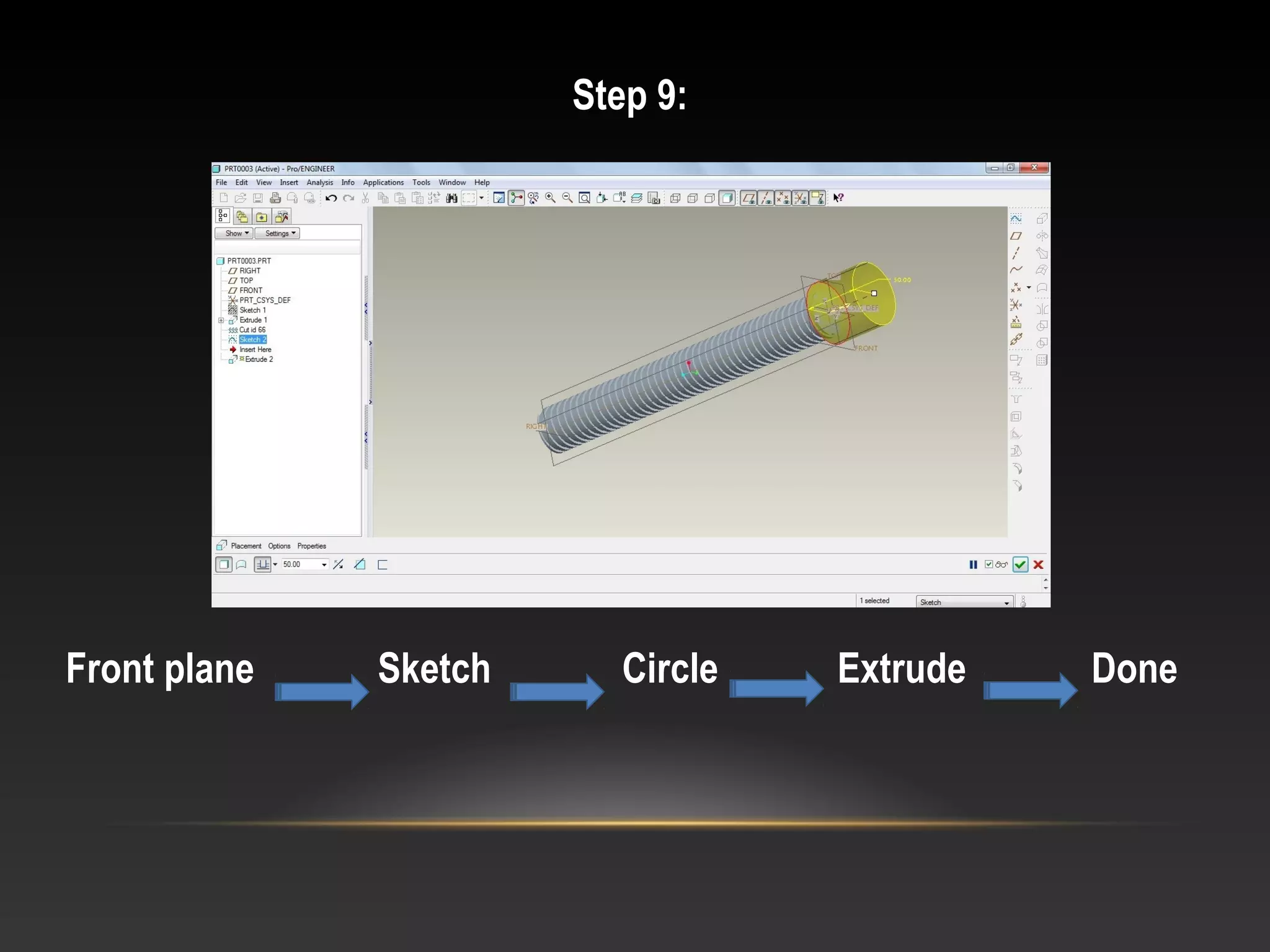

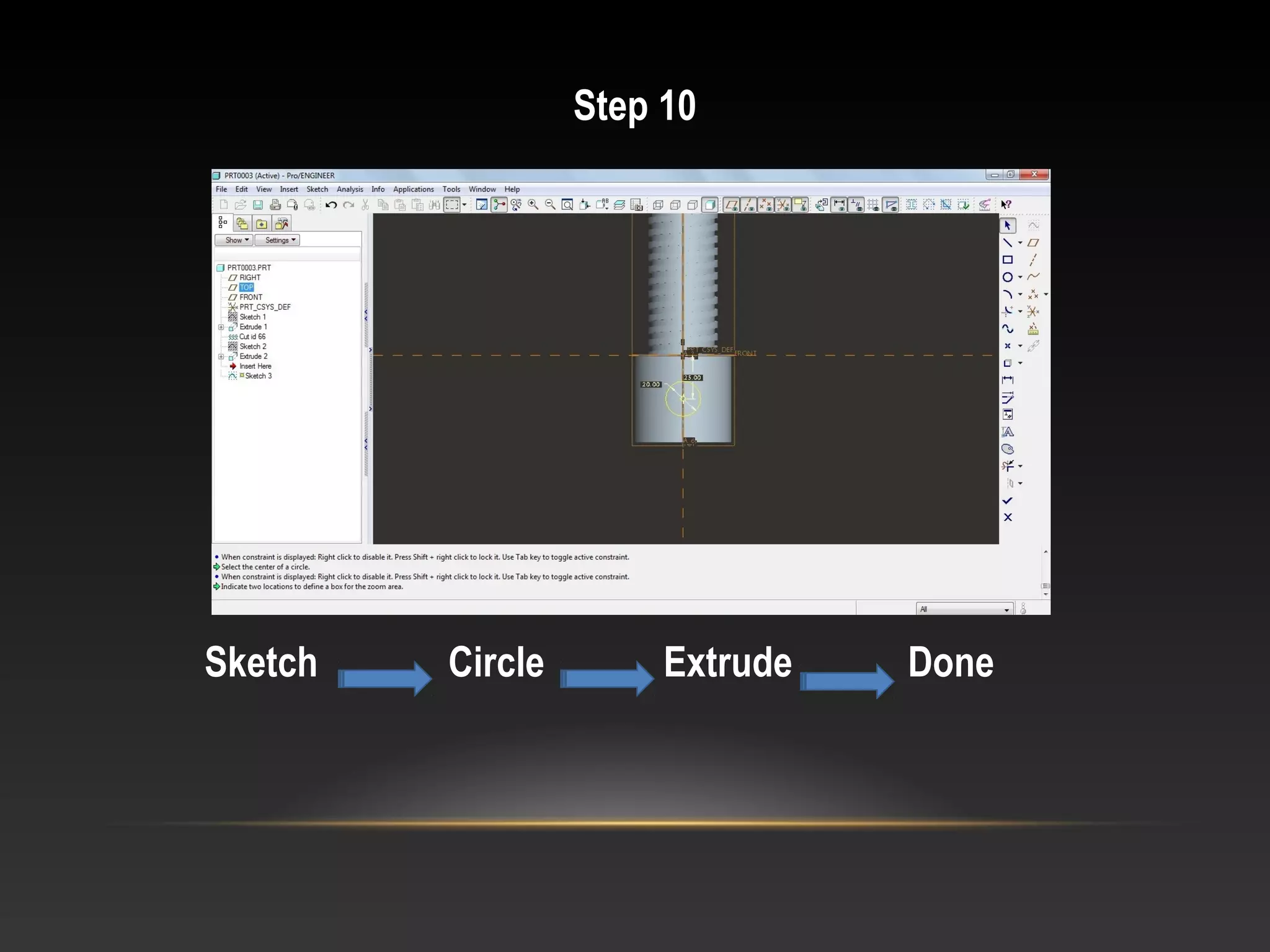

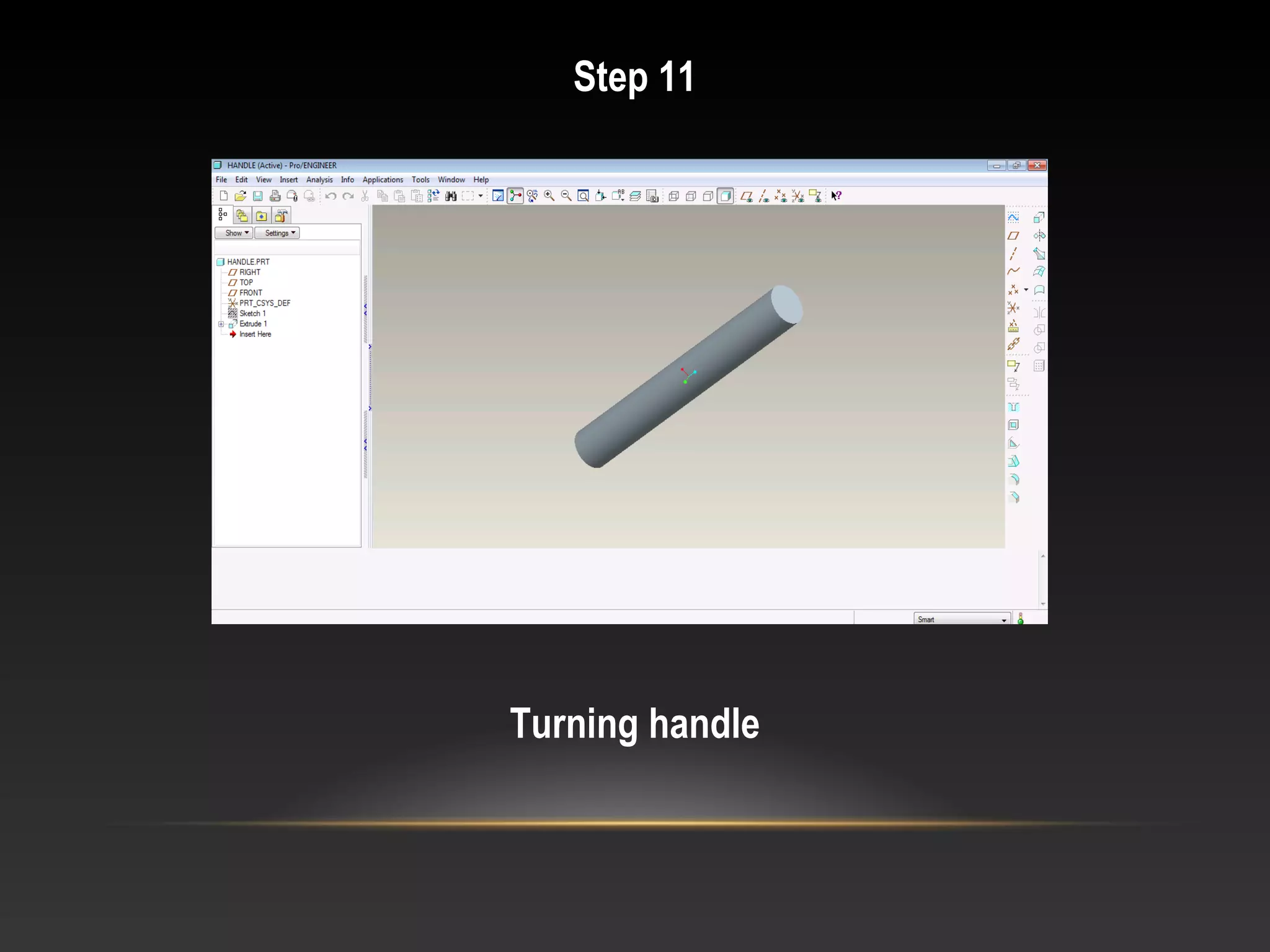

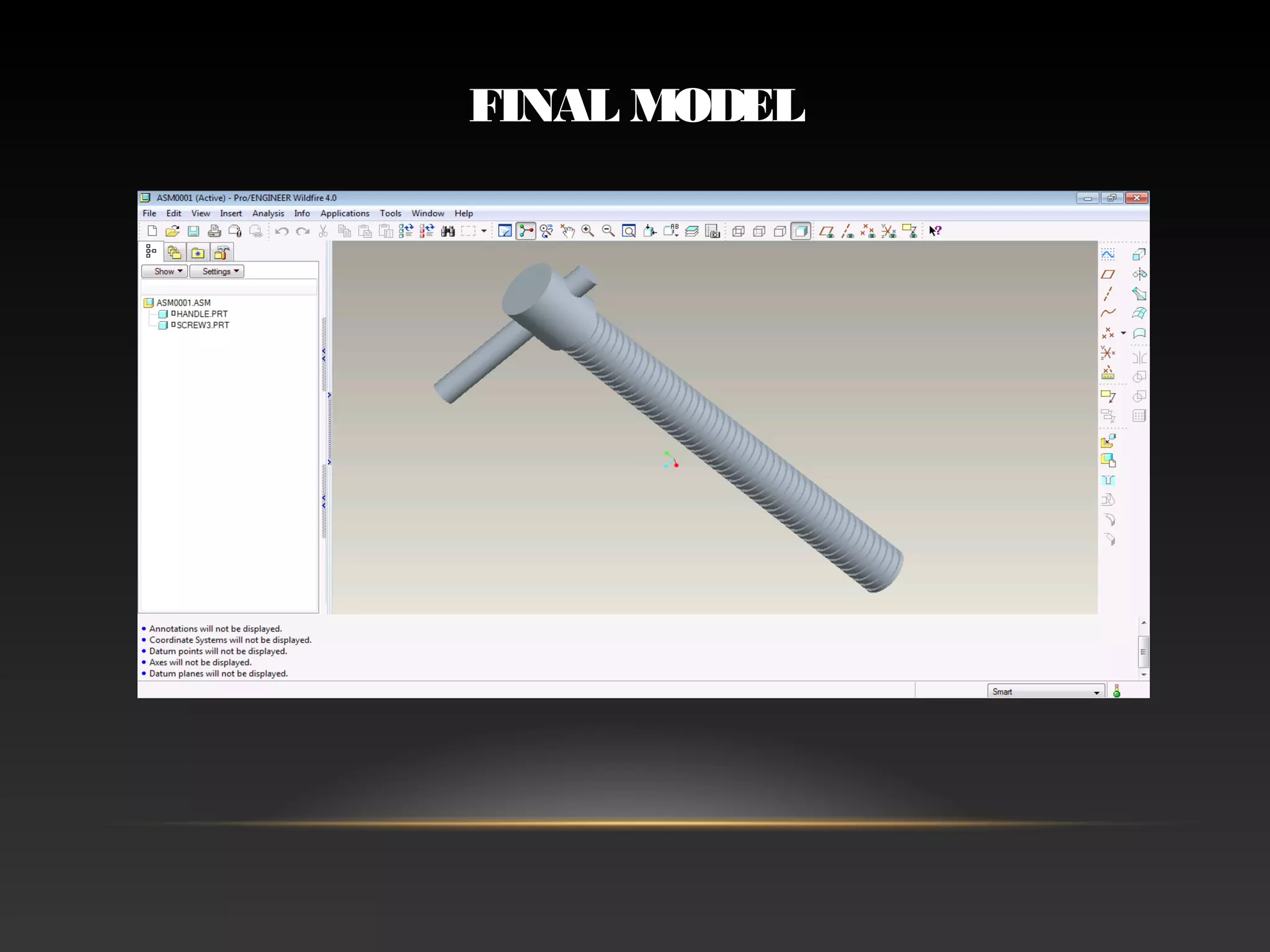

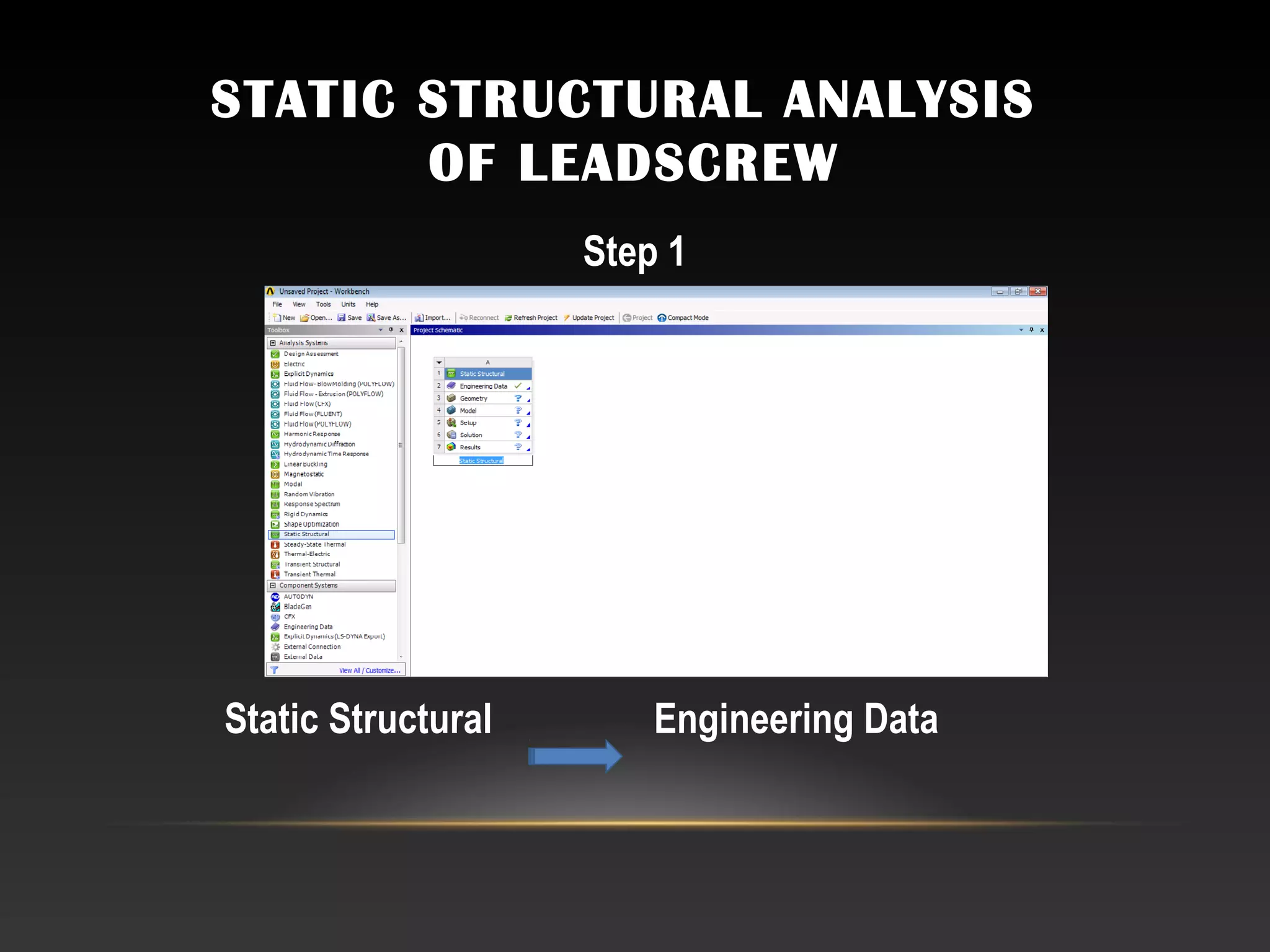

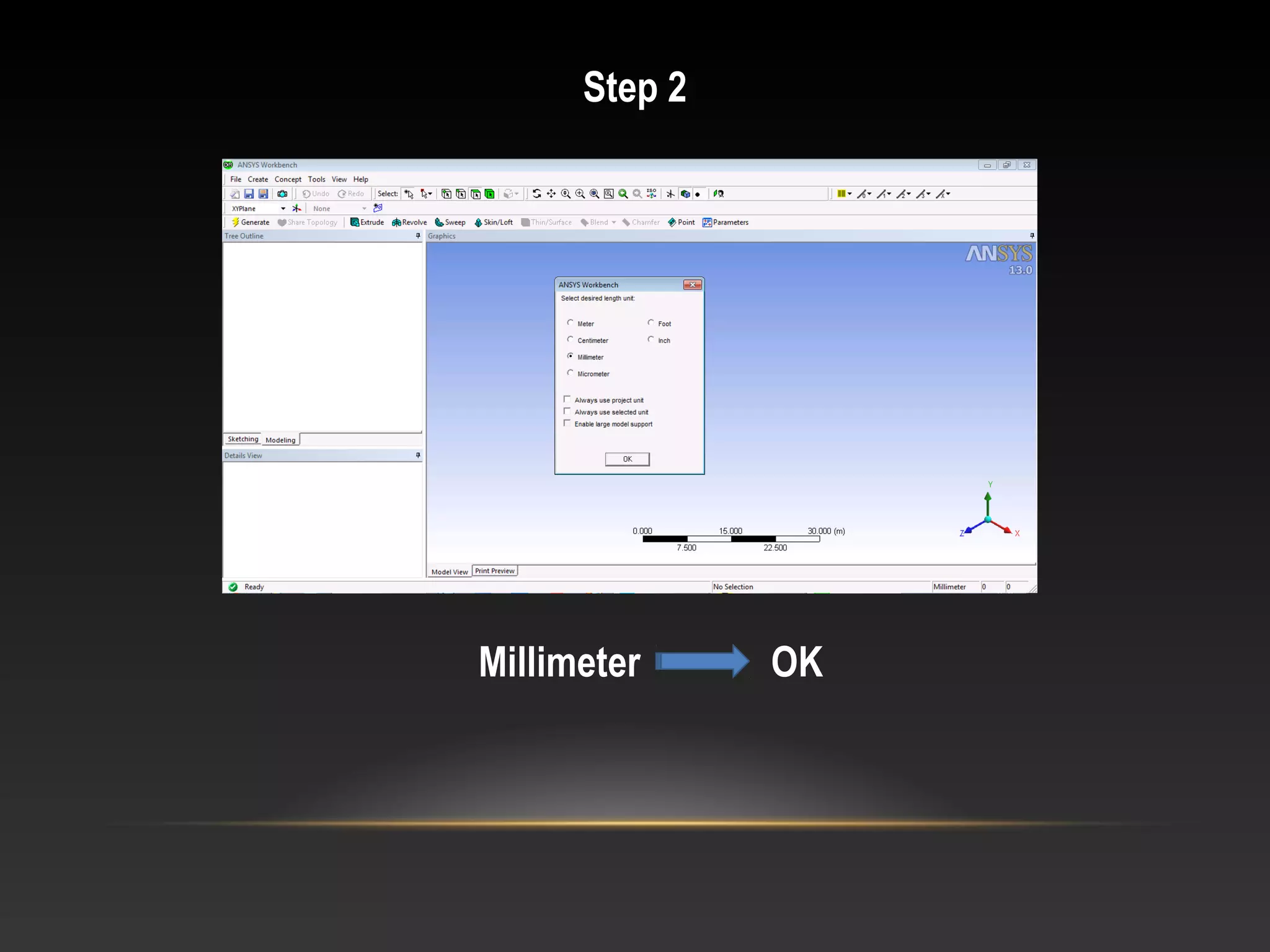

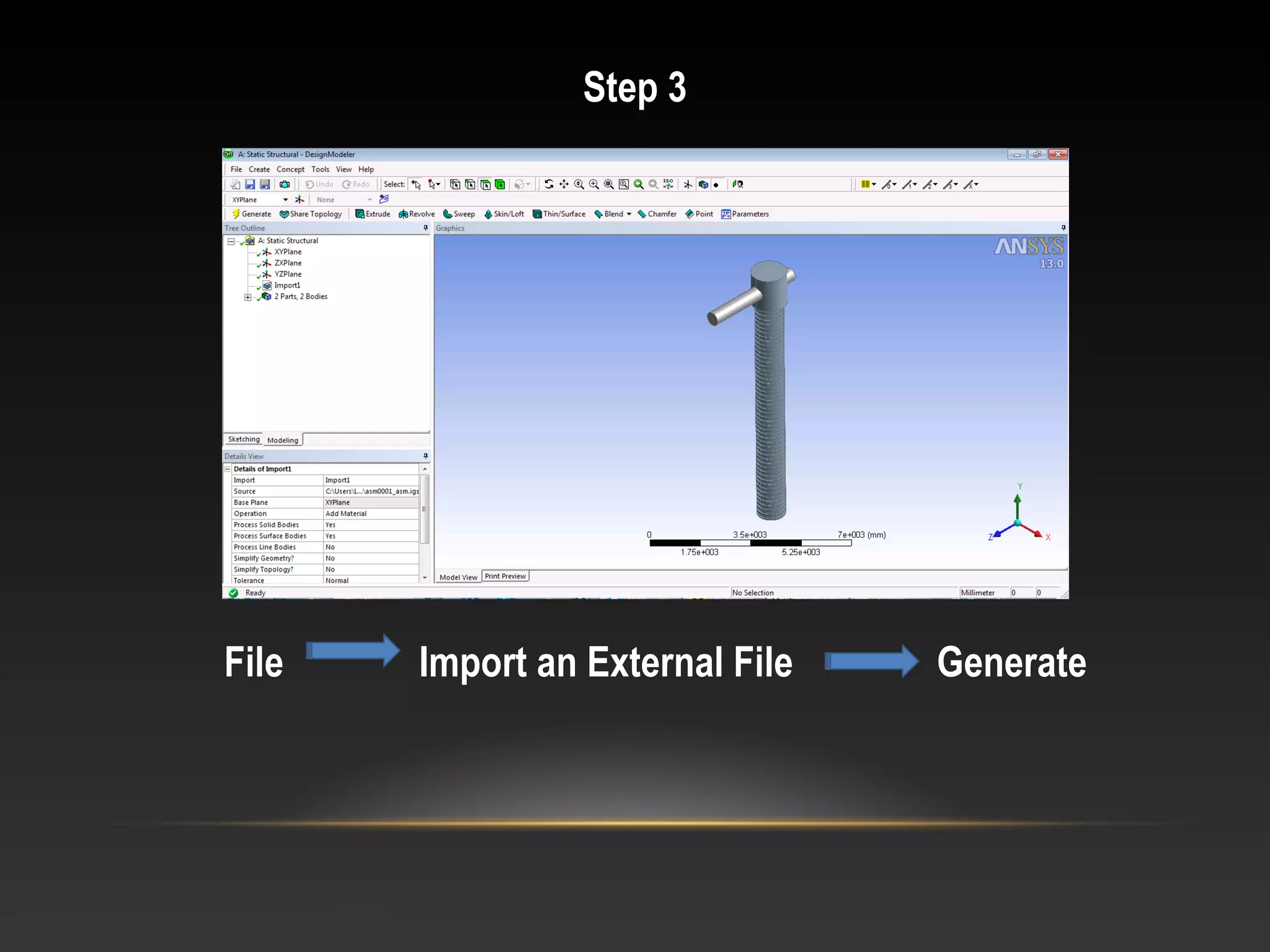

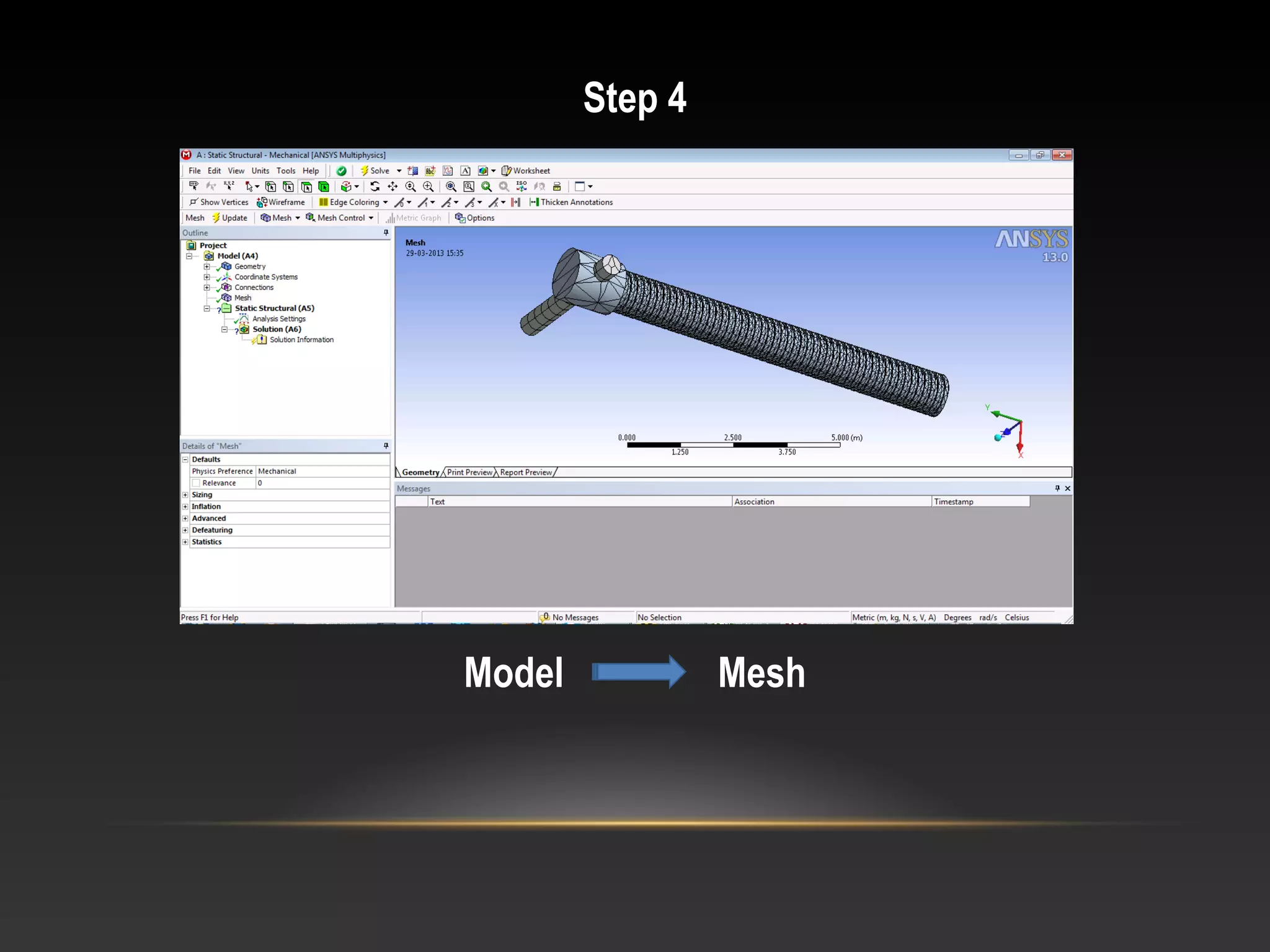

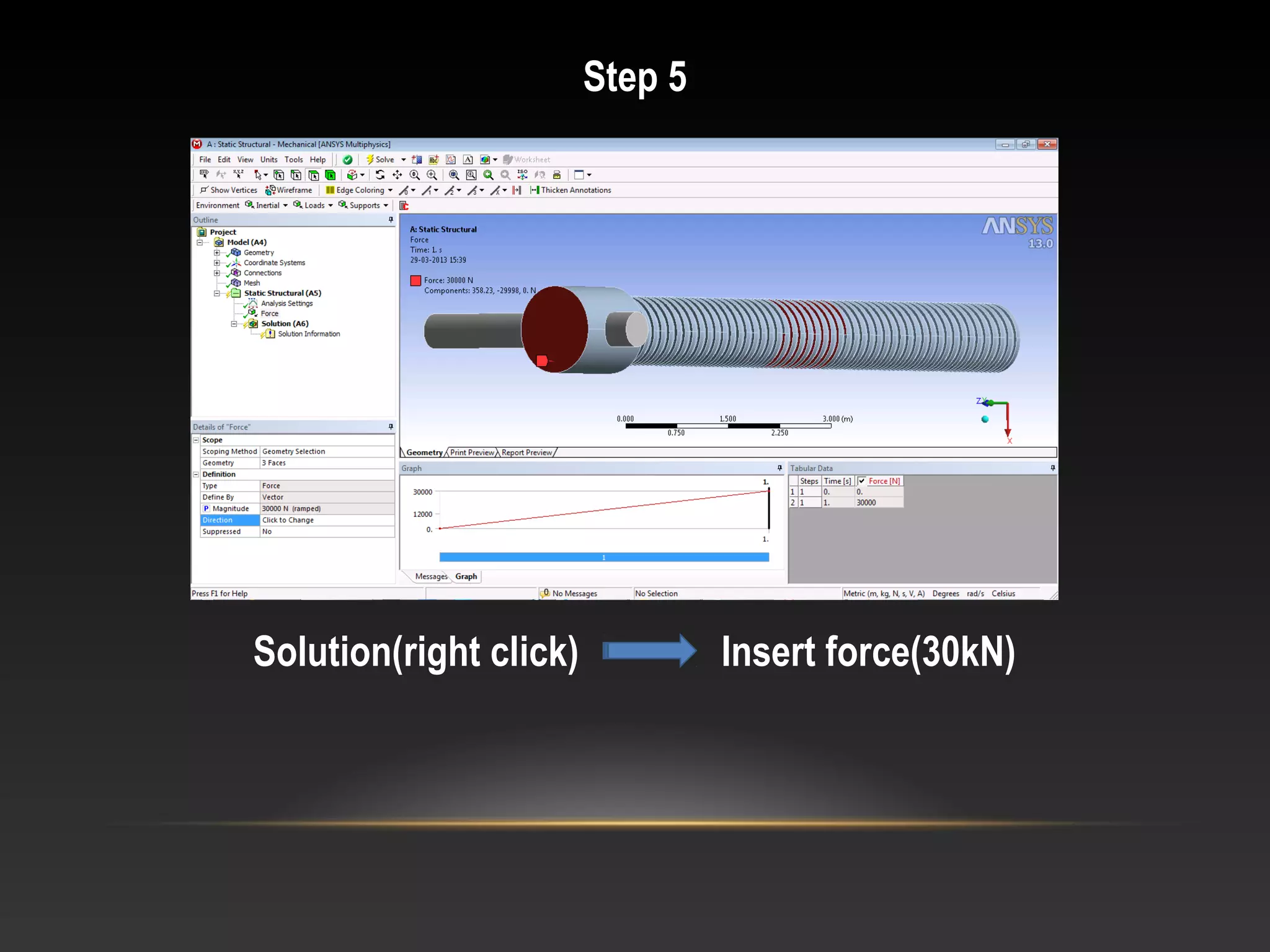

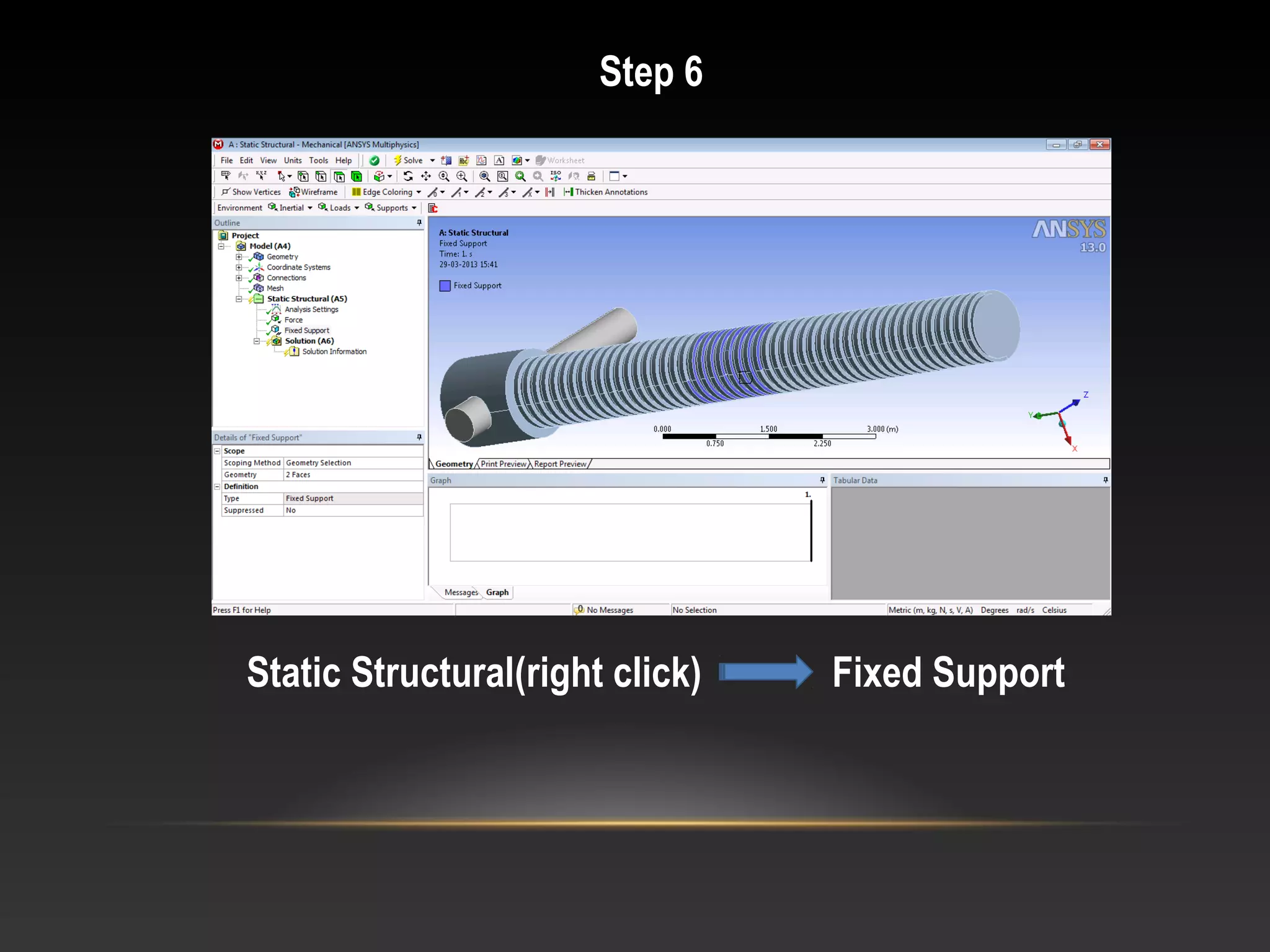

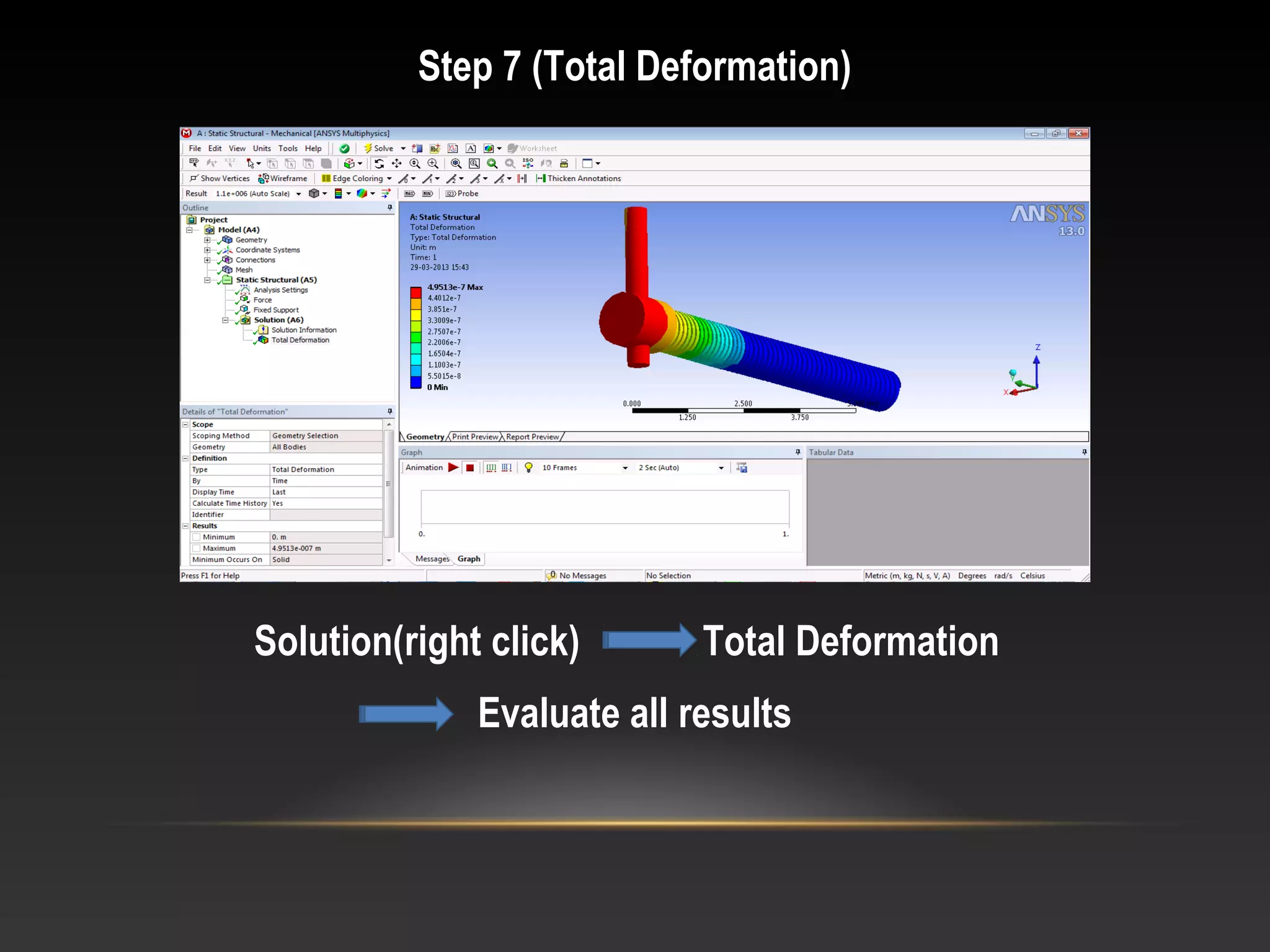

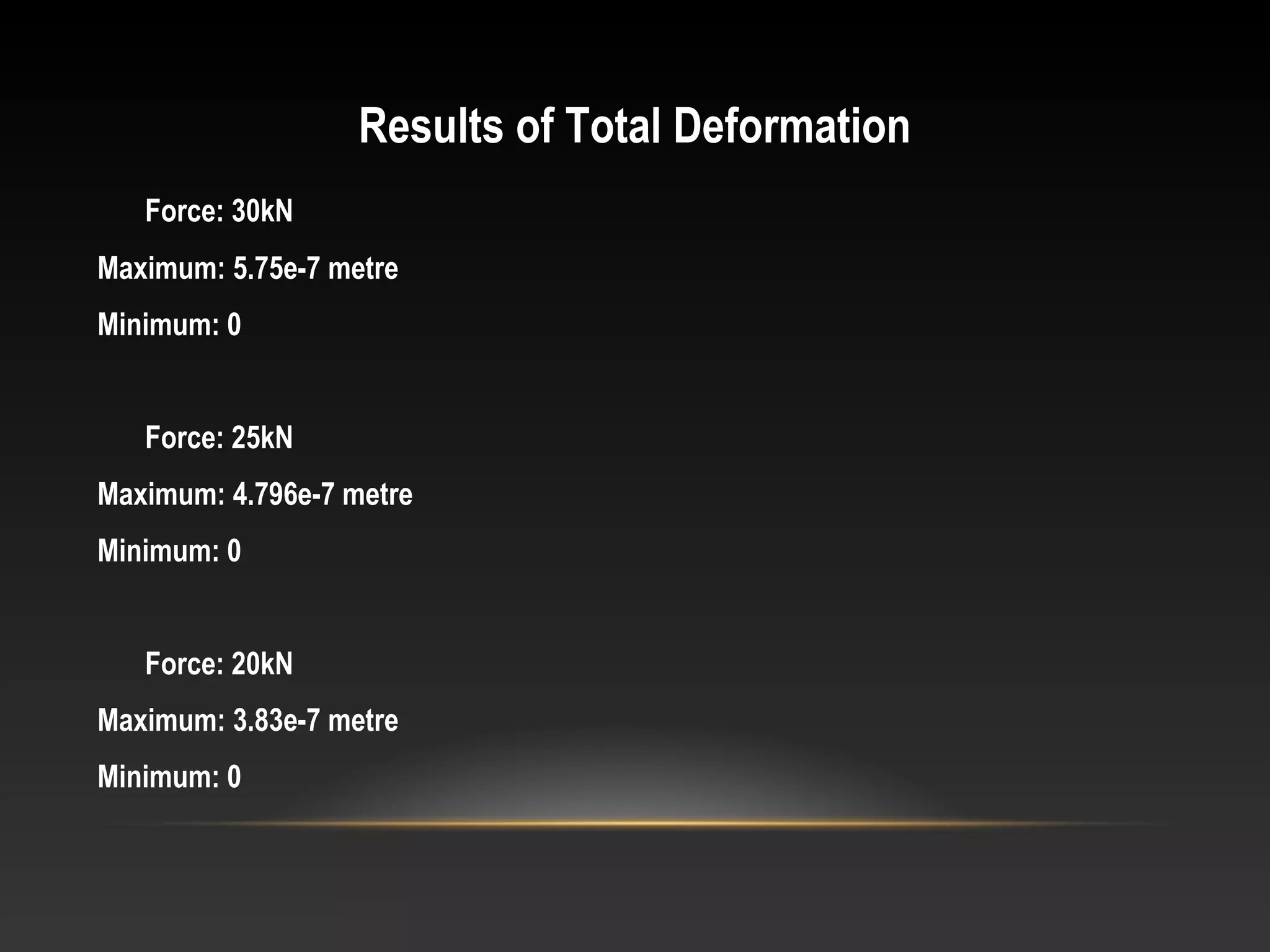

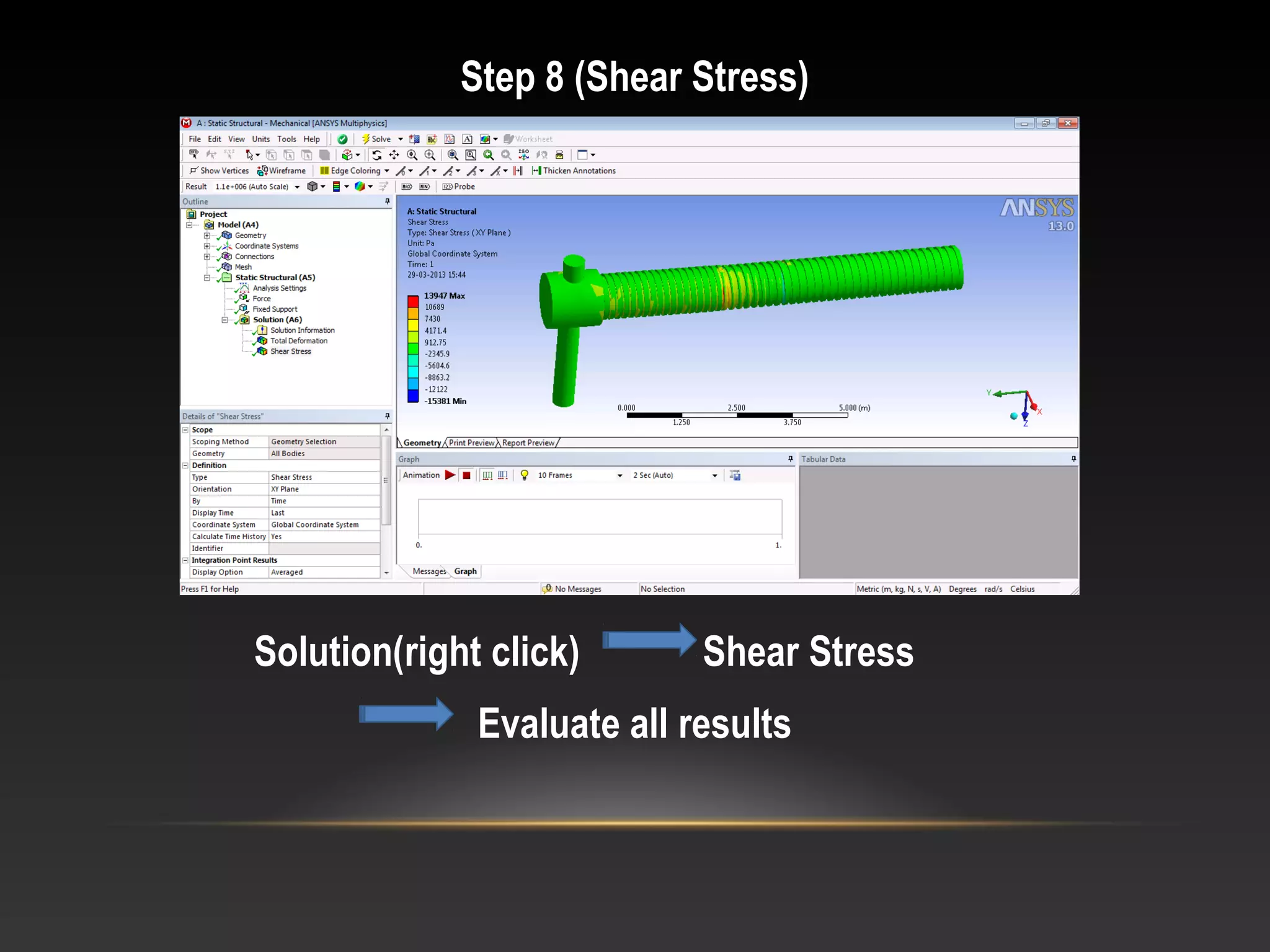

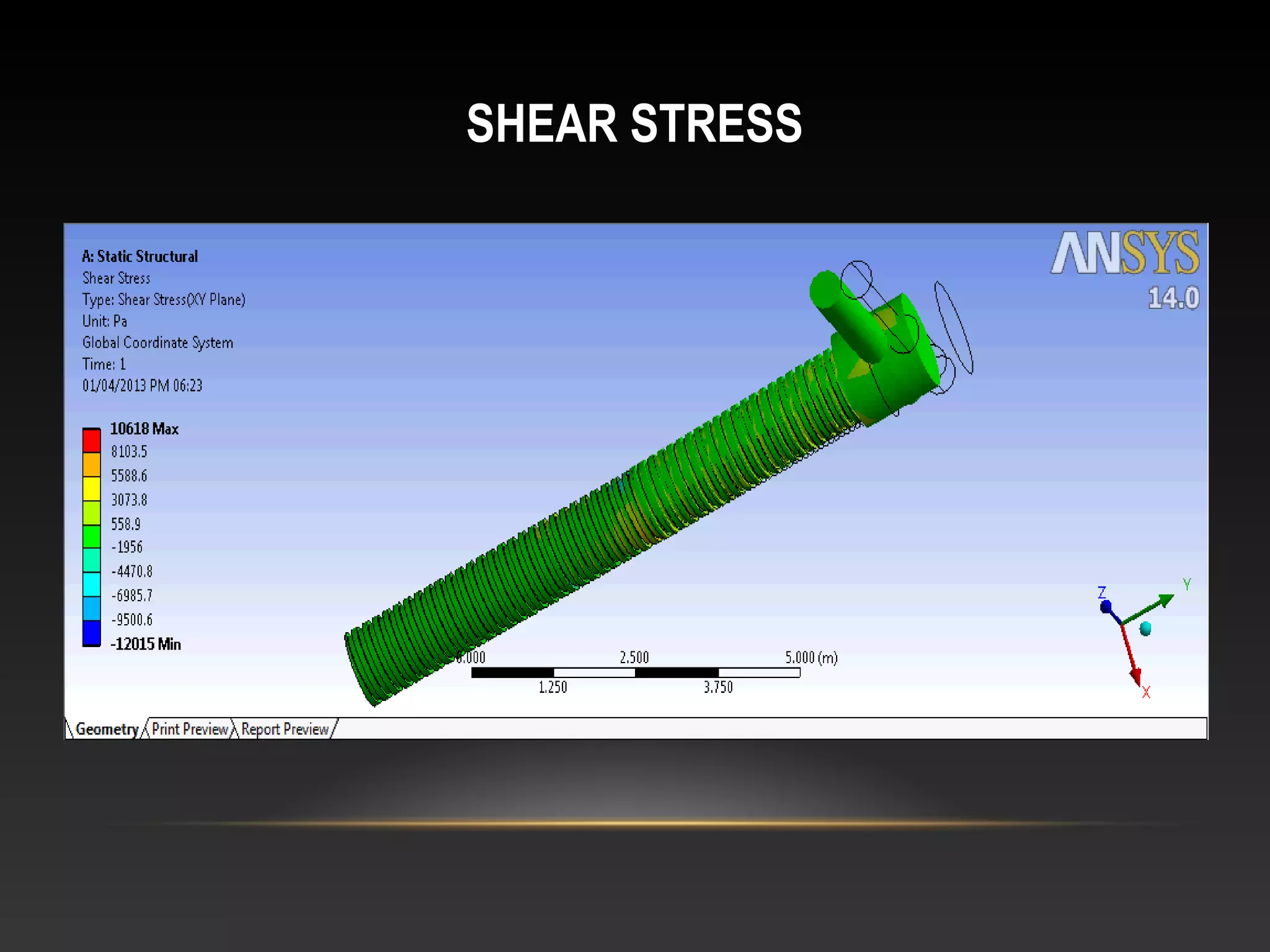

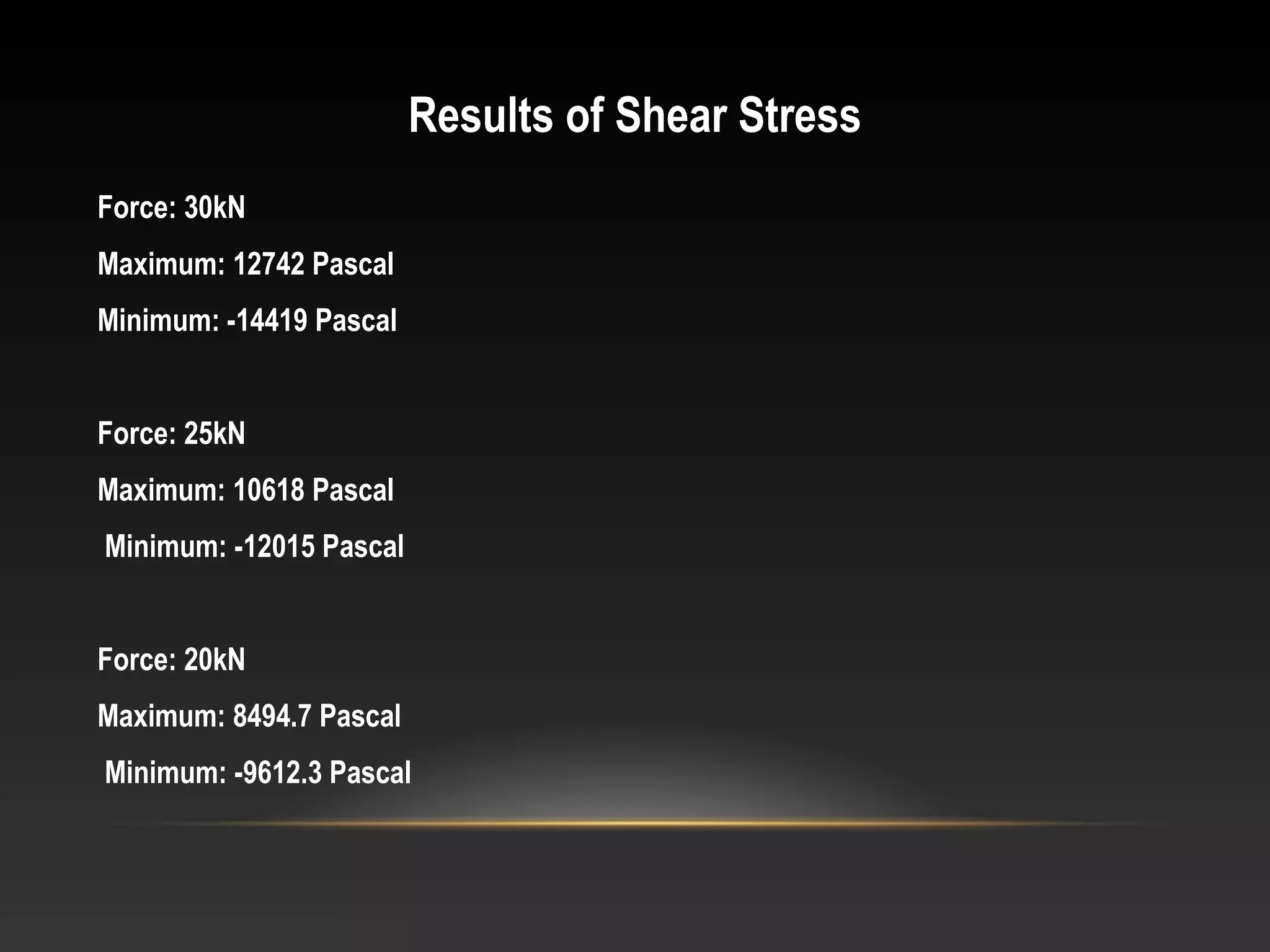

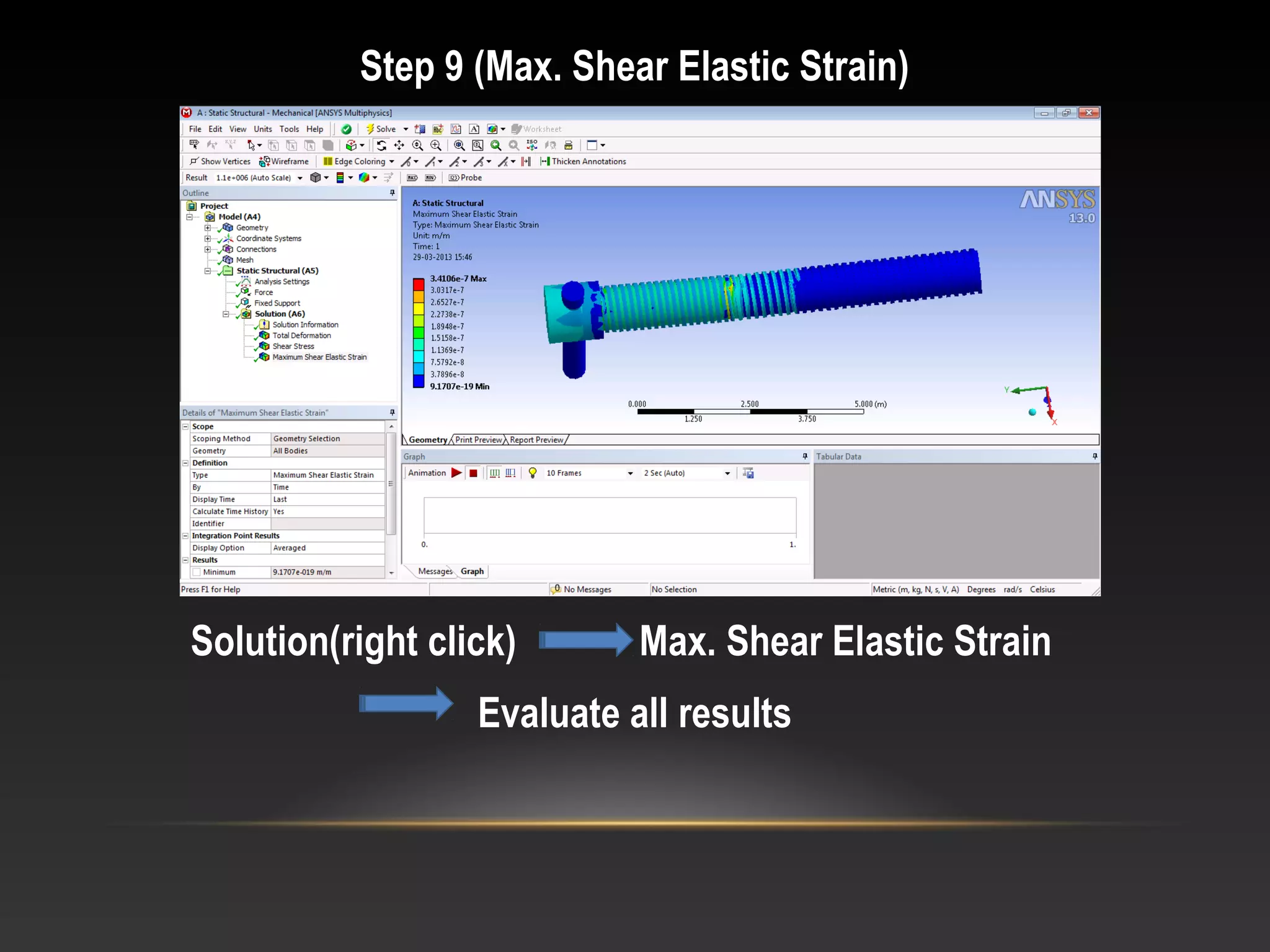

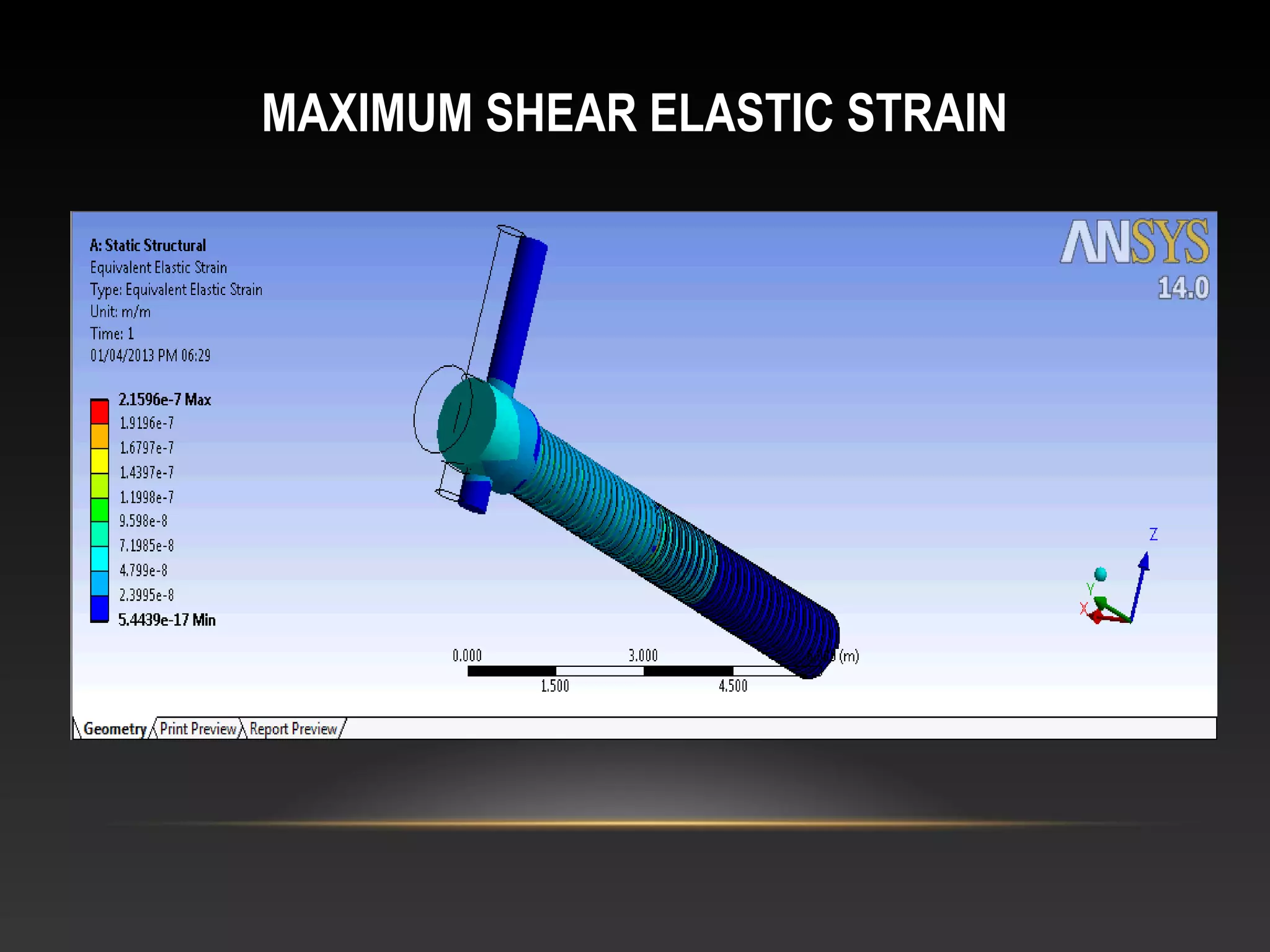

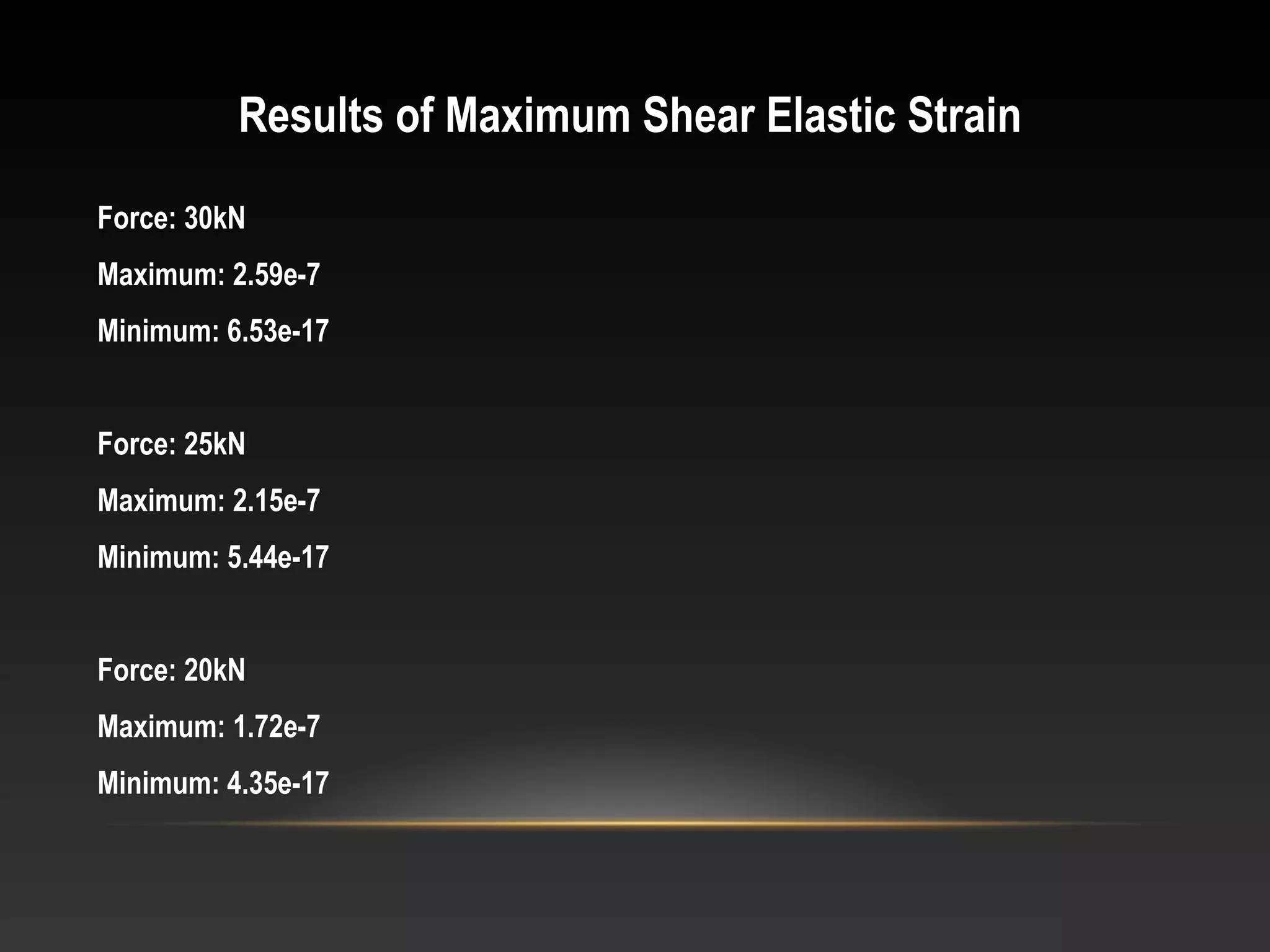

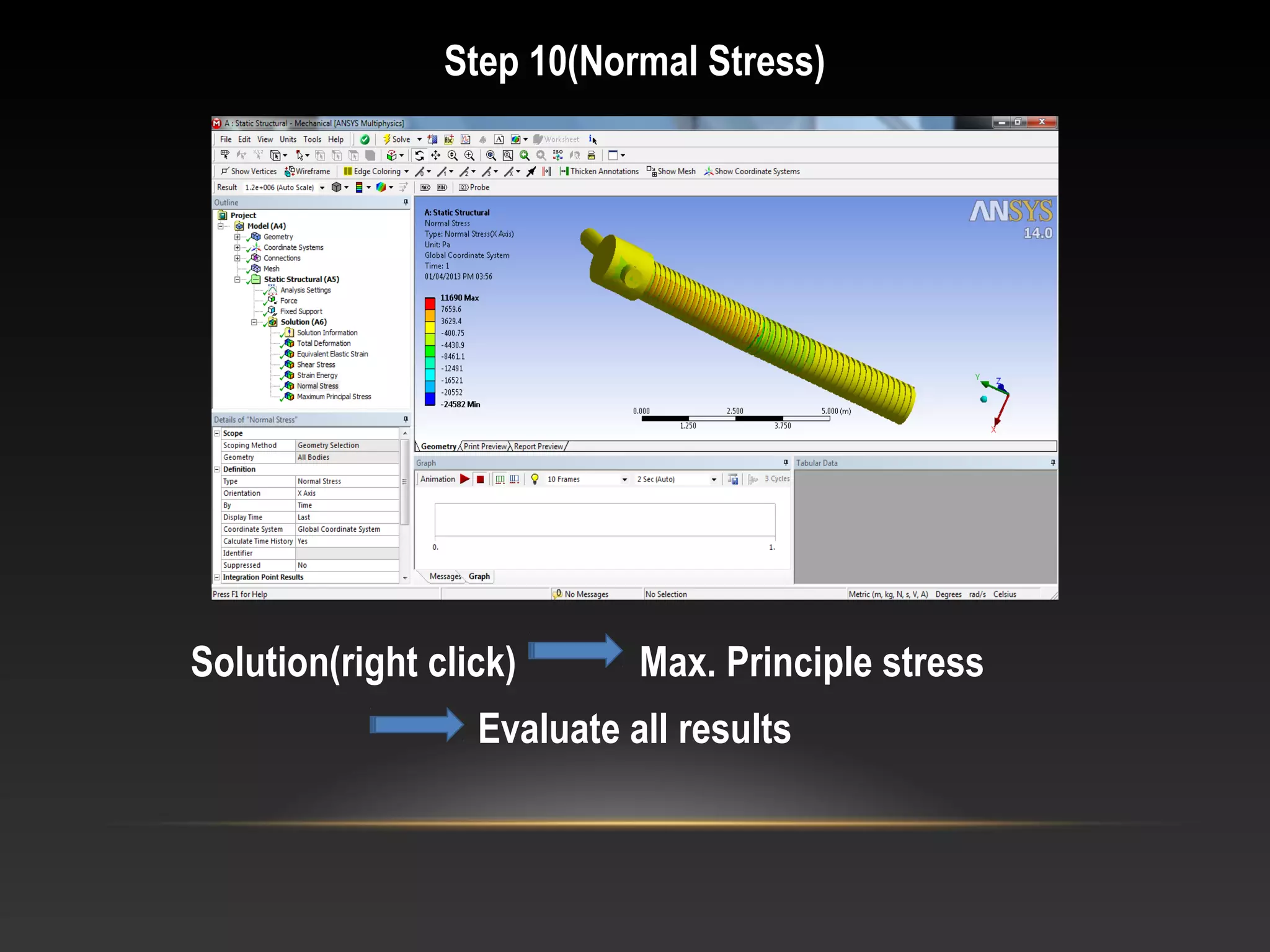

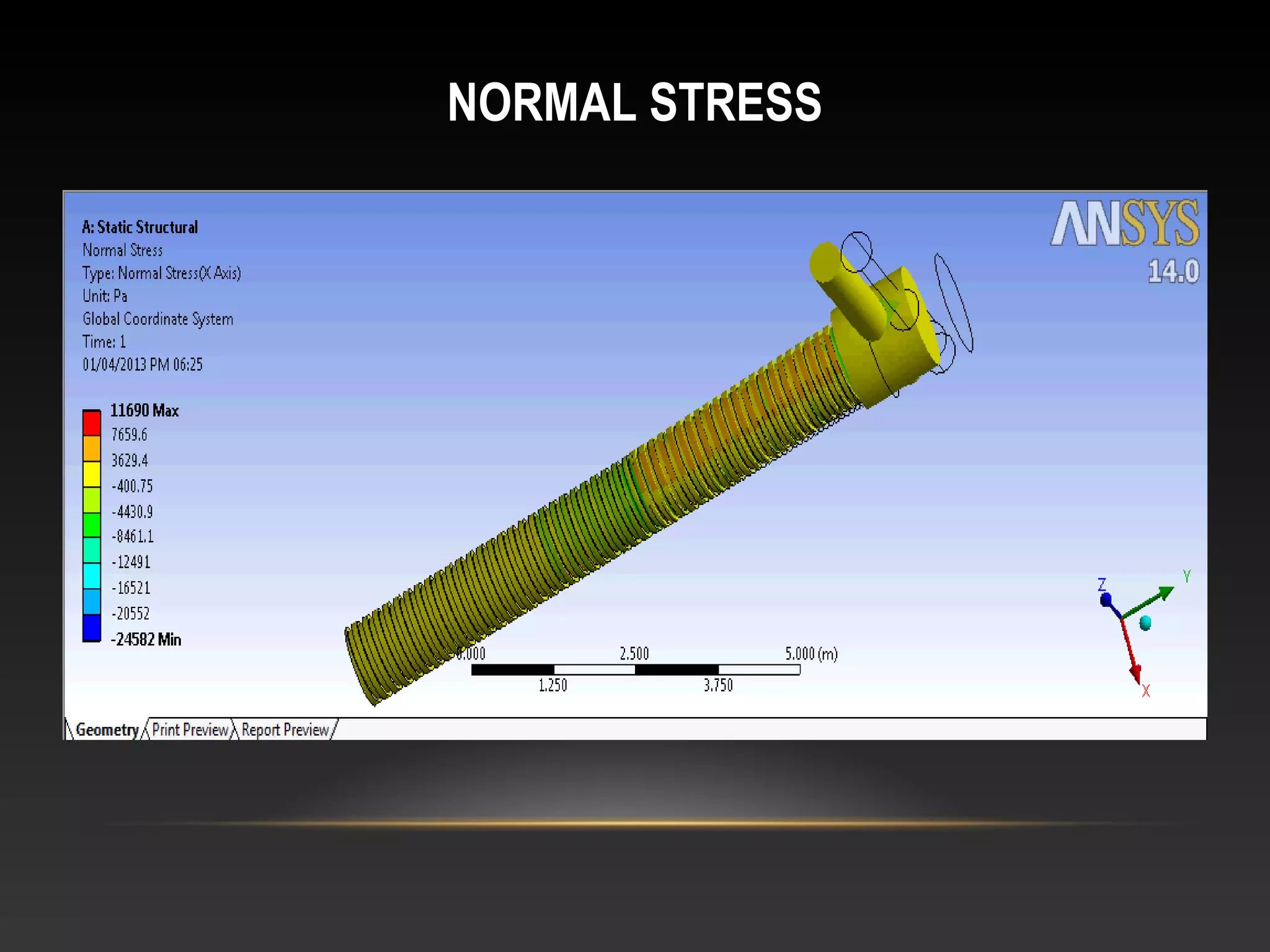

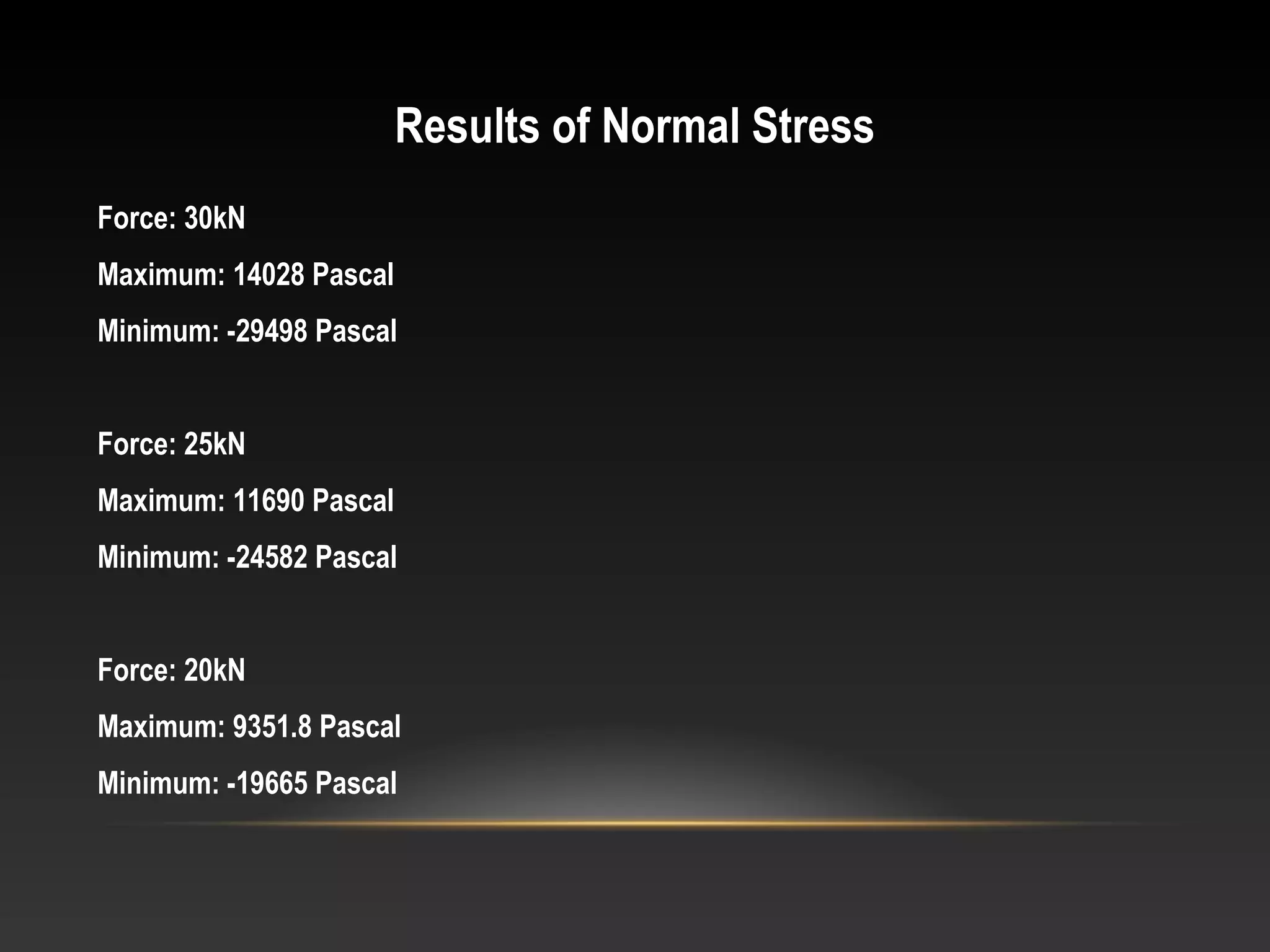

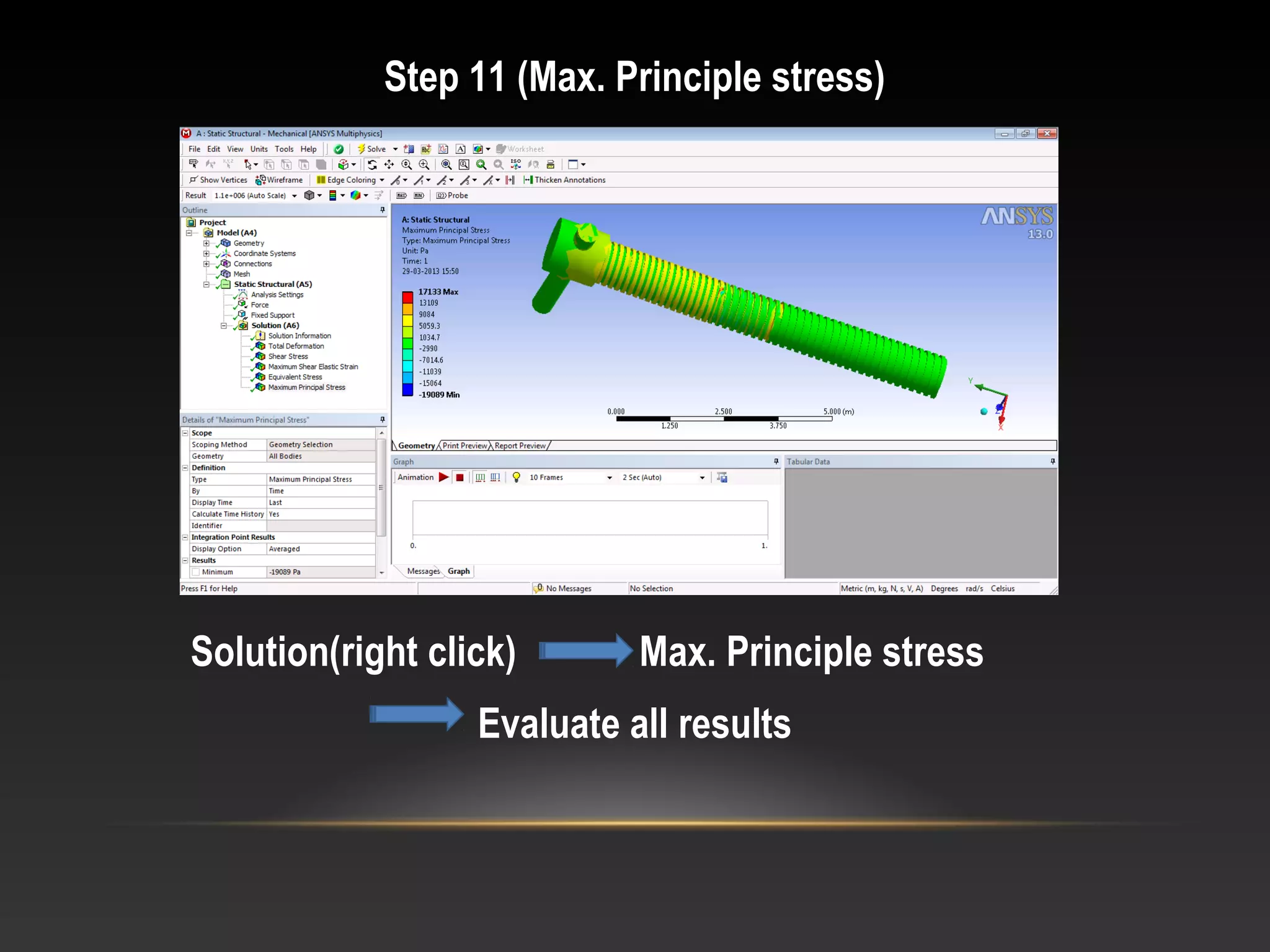

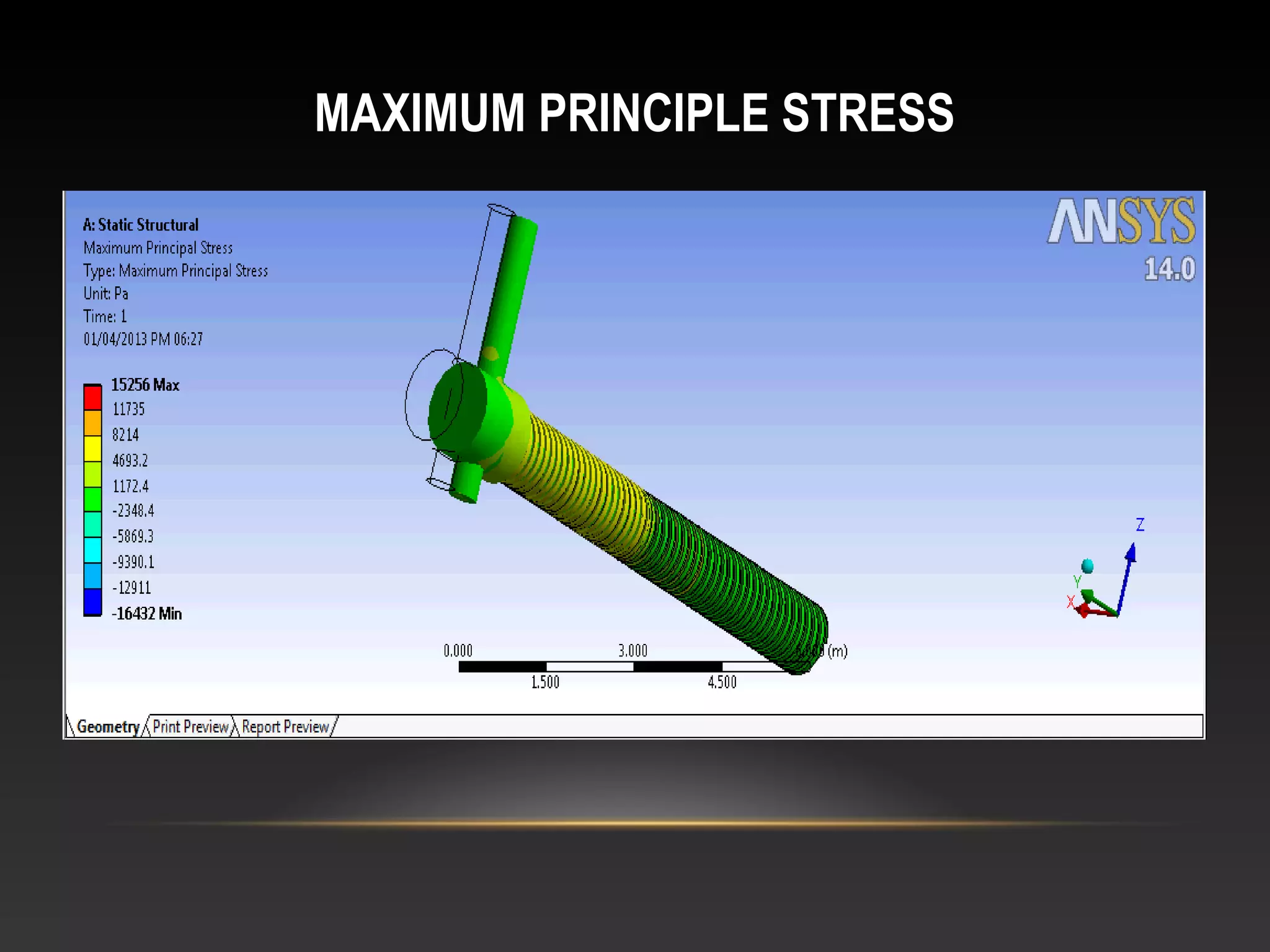

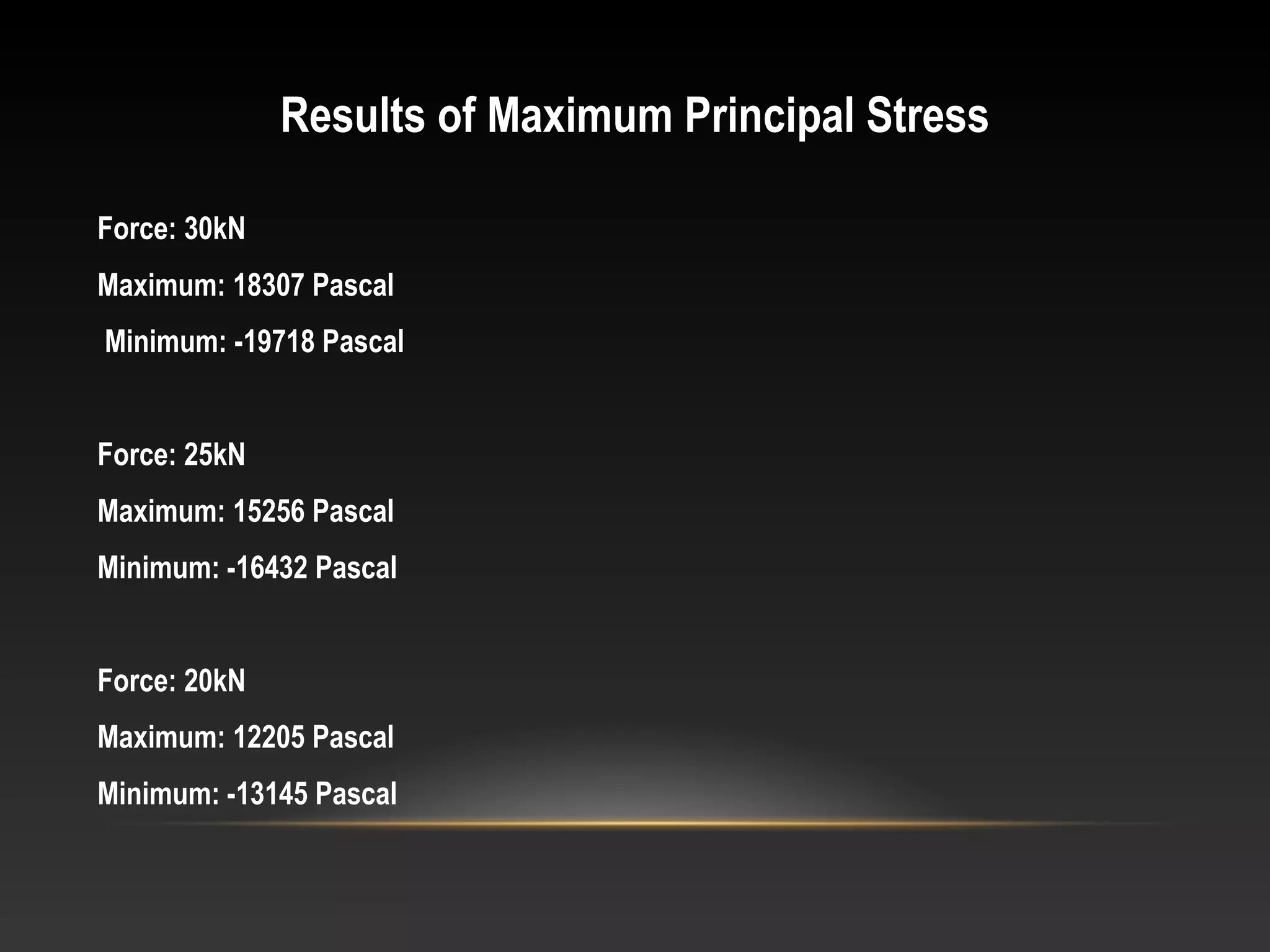

The document describes the design and analysis of a leadscrew. It includes objectives to design the leadscrew based on applied forces and stresses, model the component in PRO/E, and analyze it in ANSYS. It covers terminology, applications, screw jack design, modeling steps in PRO/E, static structural analysis in ANSYS under different loads, and results for deformation, shear stress, strain, and normal stress. The analysis found the leadscrew does not fail under the applied forces and shows satisfactory results for reduced load values.