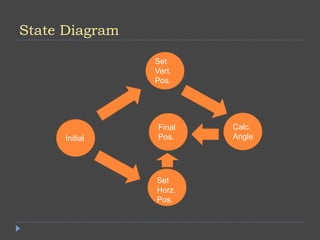

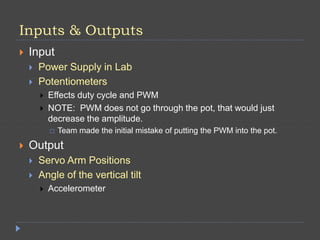

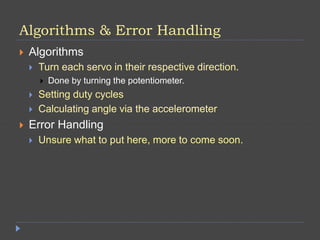

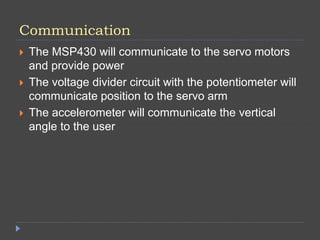

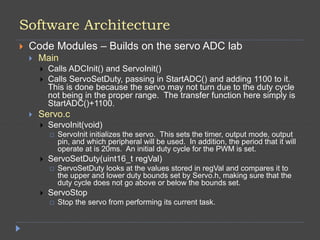

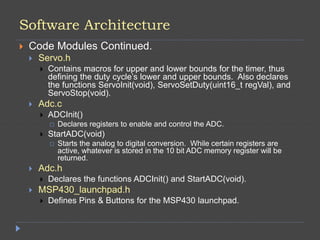

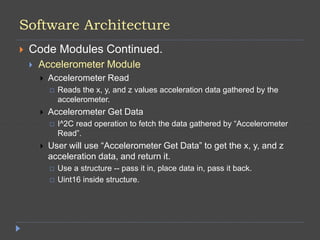

The document describes a smart mount system that uses two servo motors controlled by an MSP430 microprocessor to adjust the vertical and horizontal tilt of the mount based on input from a potentiometer and accelerometer. The system includes code modules for initializing and controlling the servos and reading acceleration data to calculate the vertical angle of the mount. Safety considerations include not overloading the servos and ensuring a stable structure.