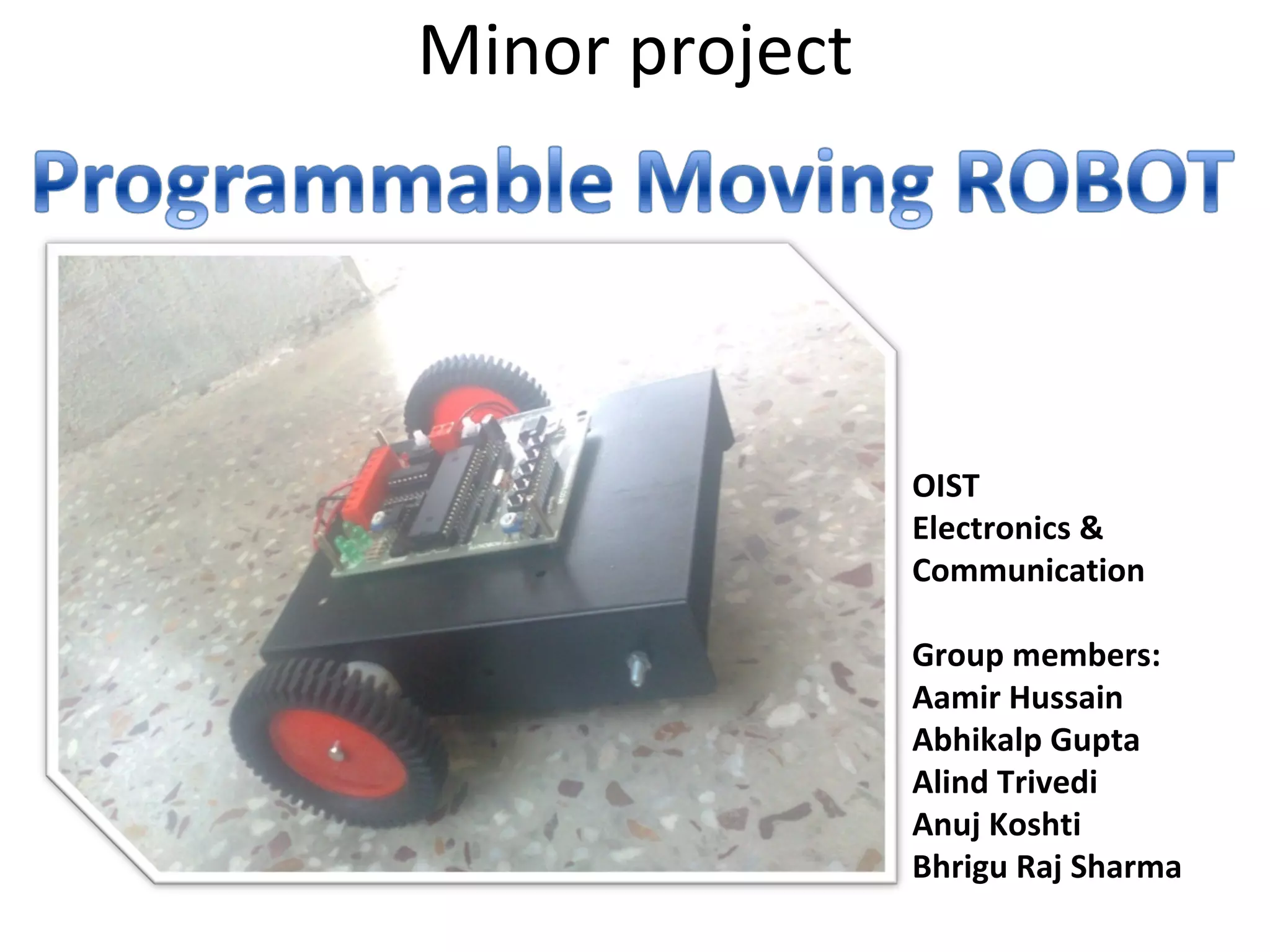

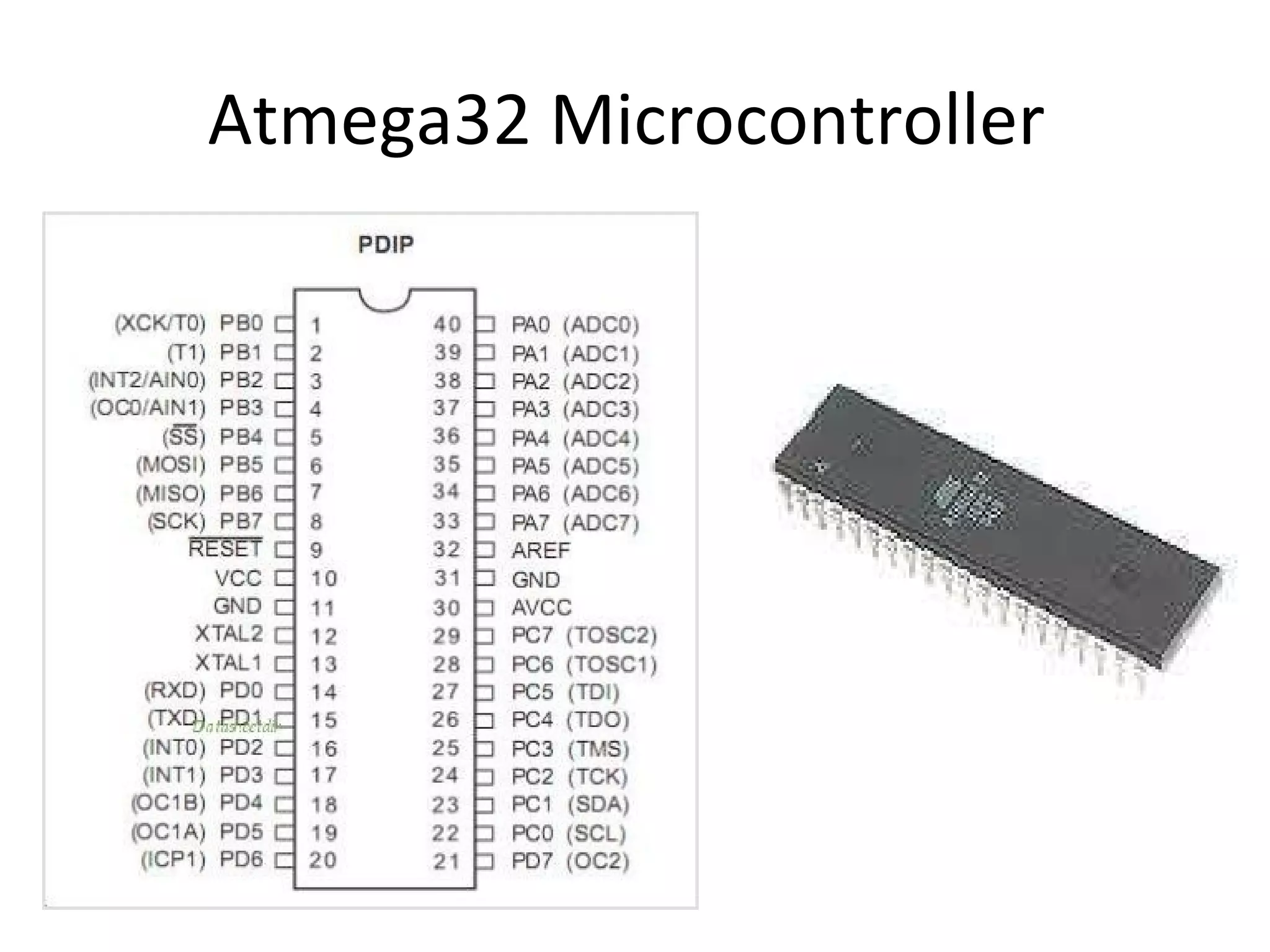

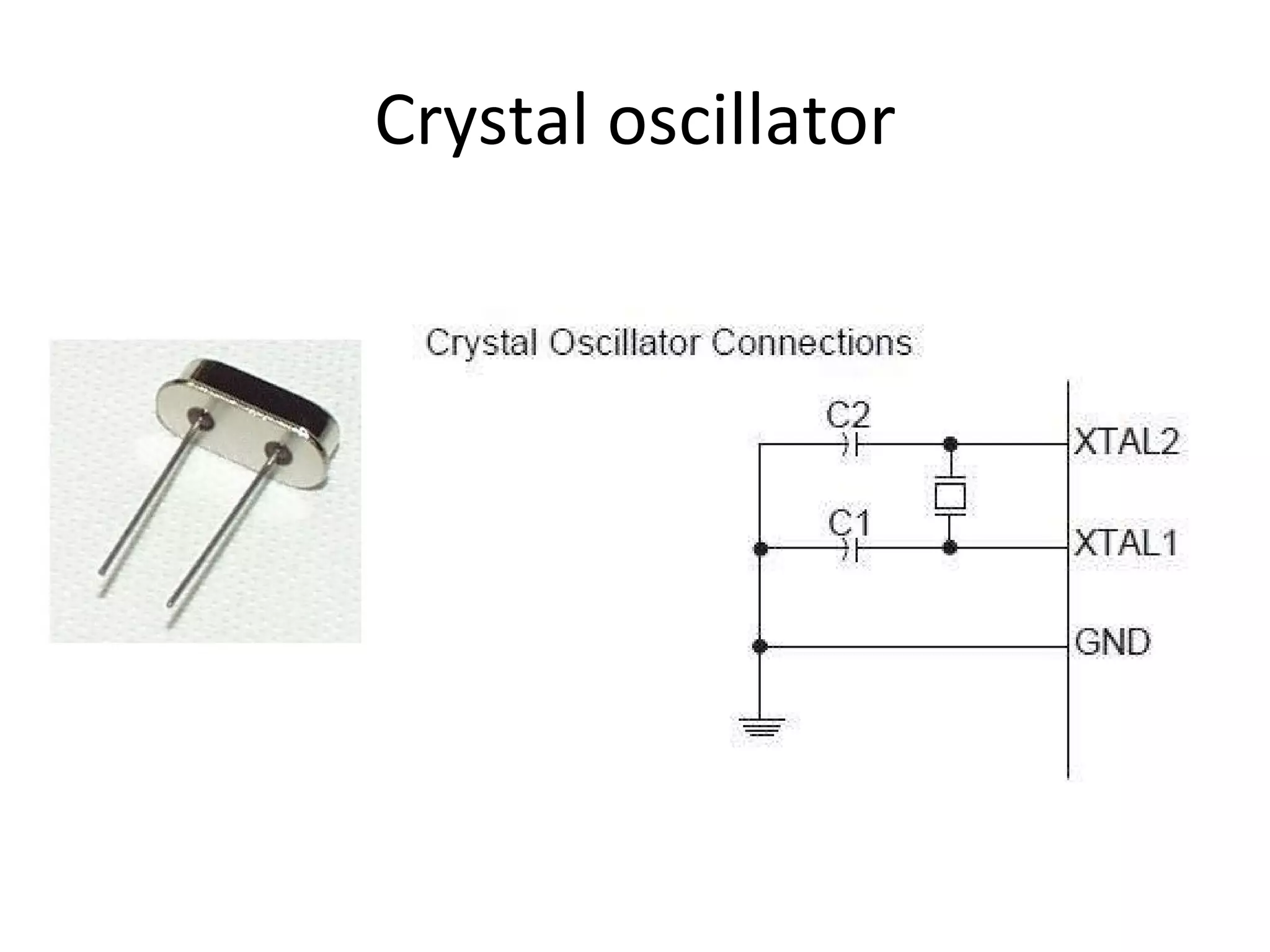

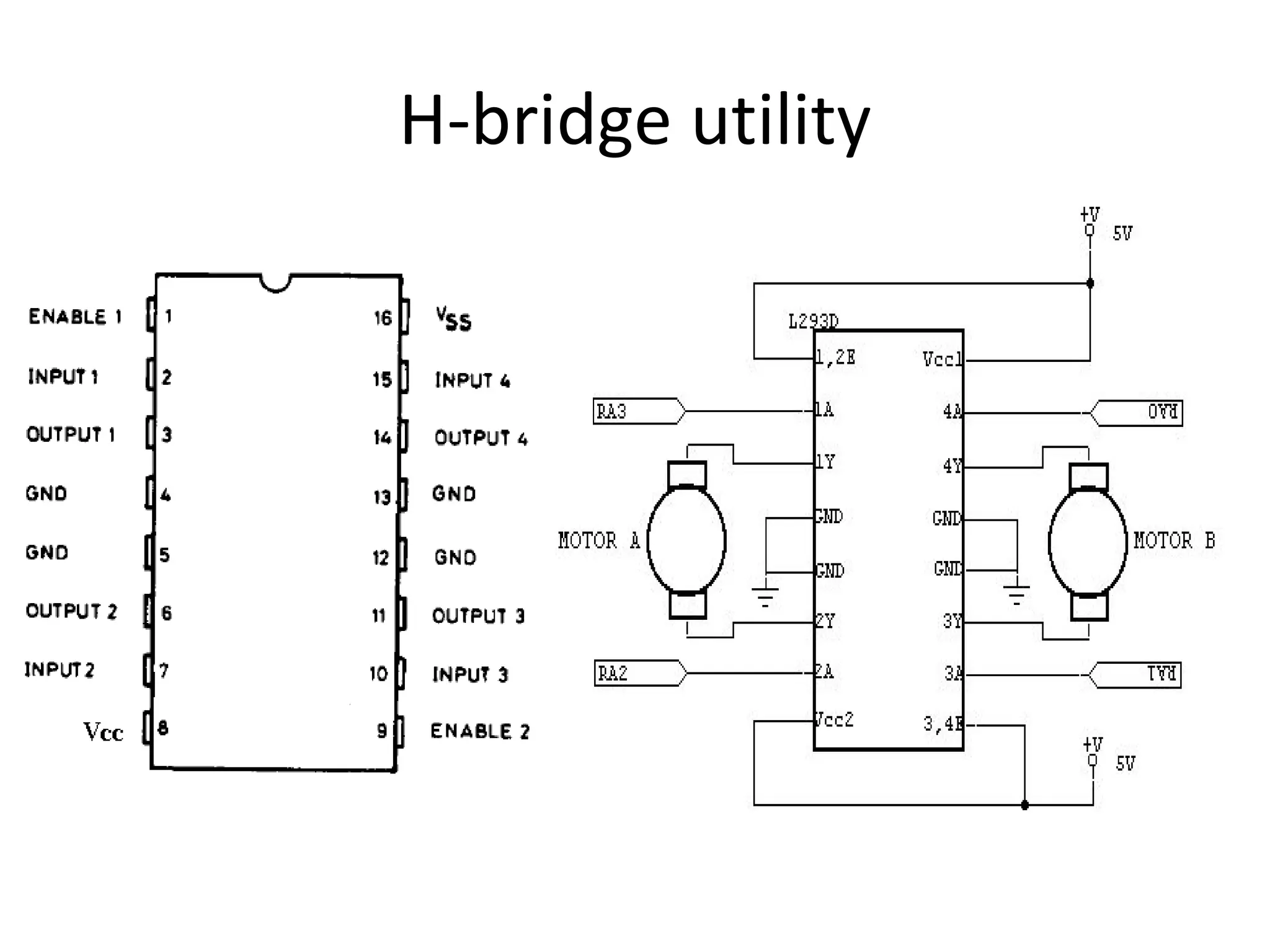

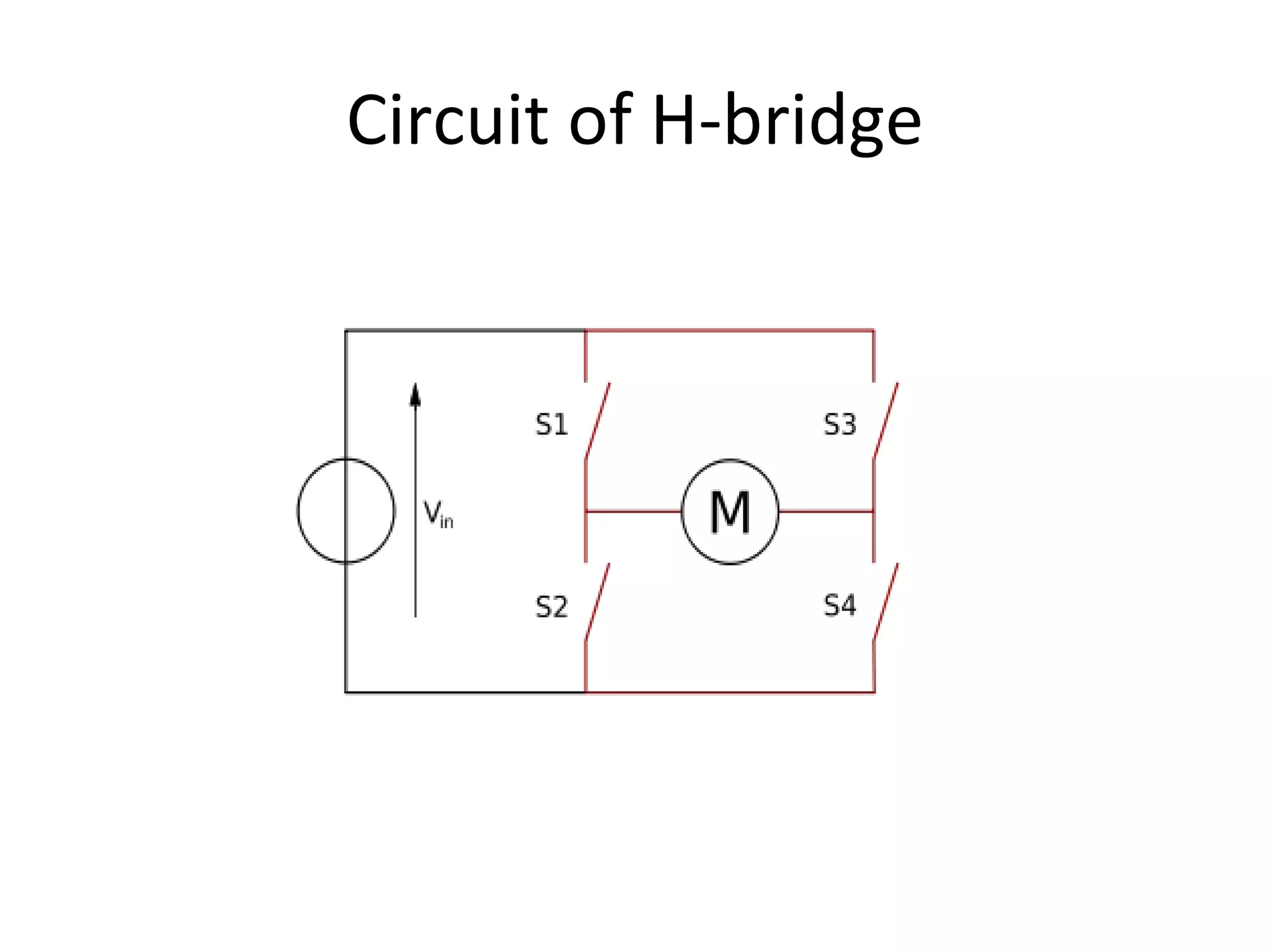

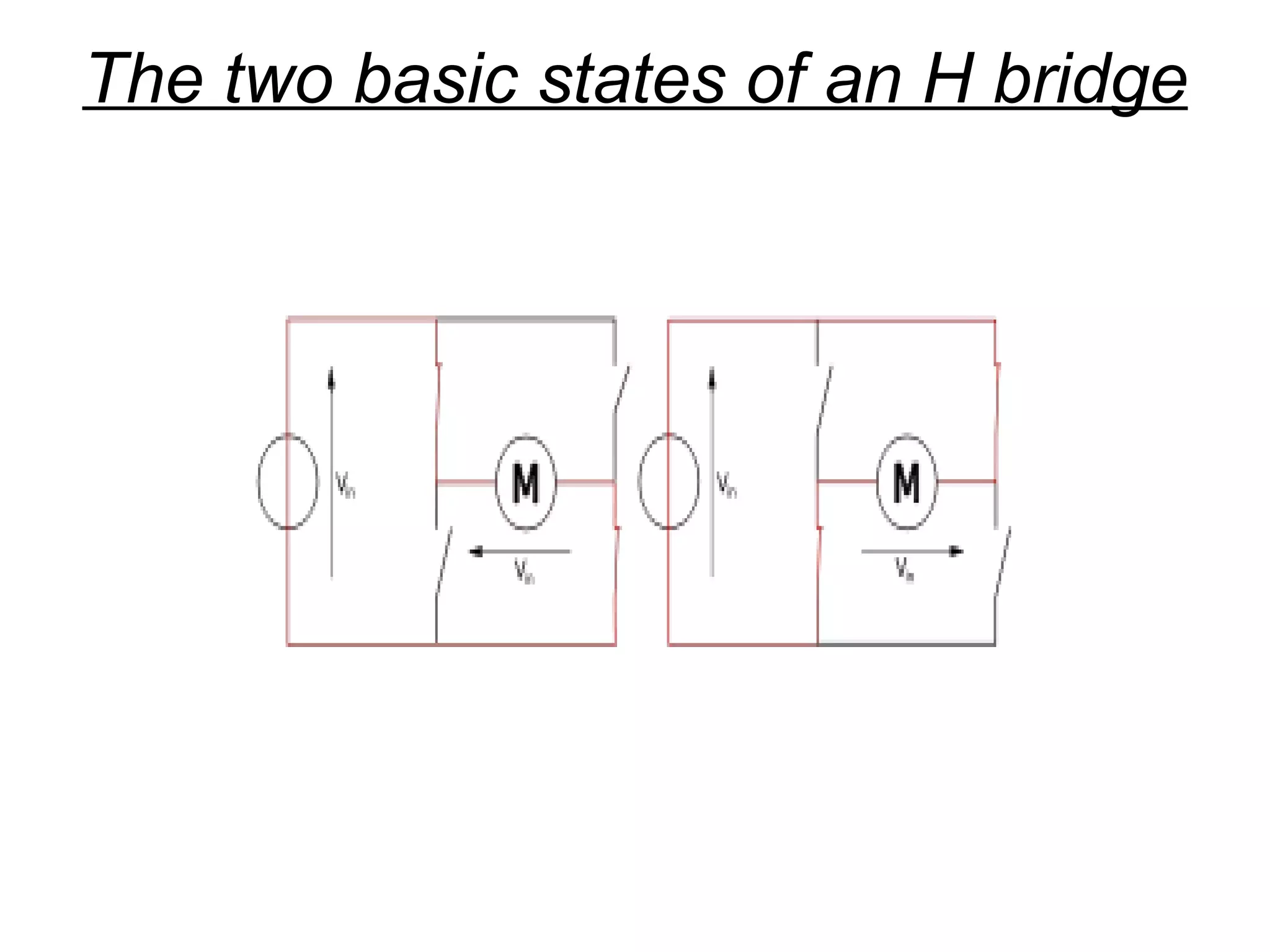

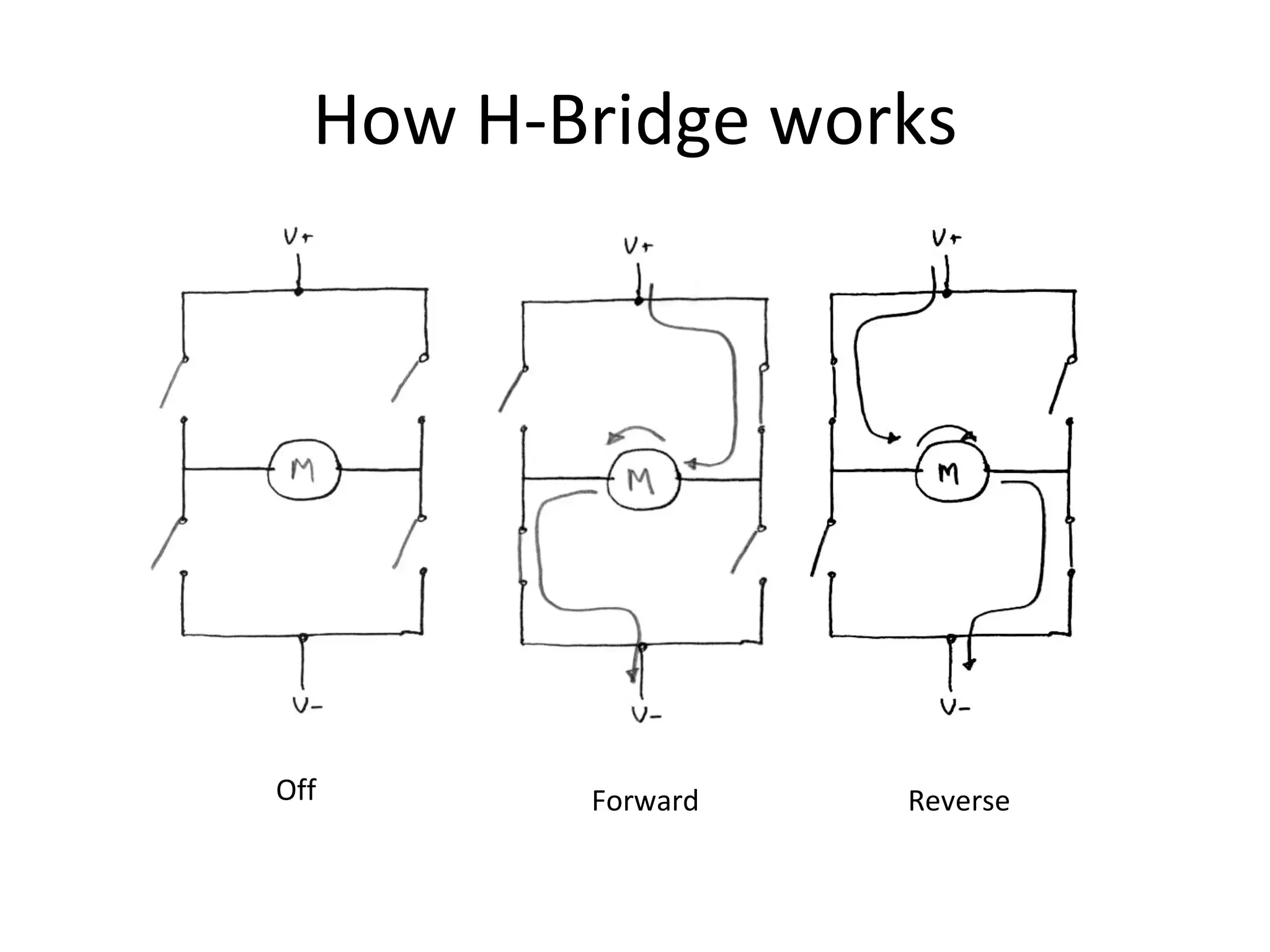

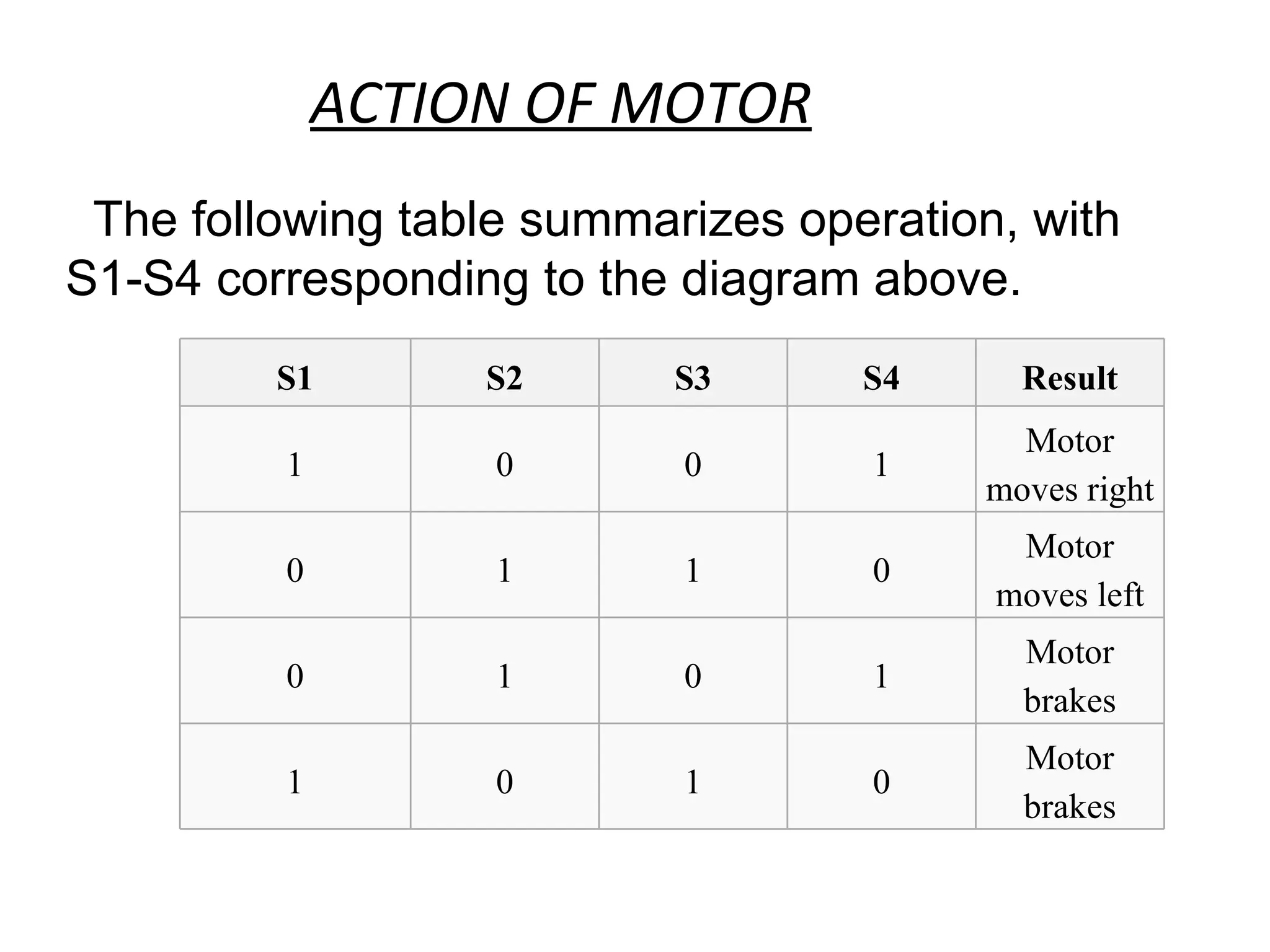

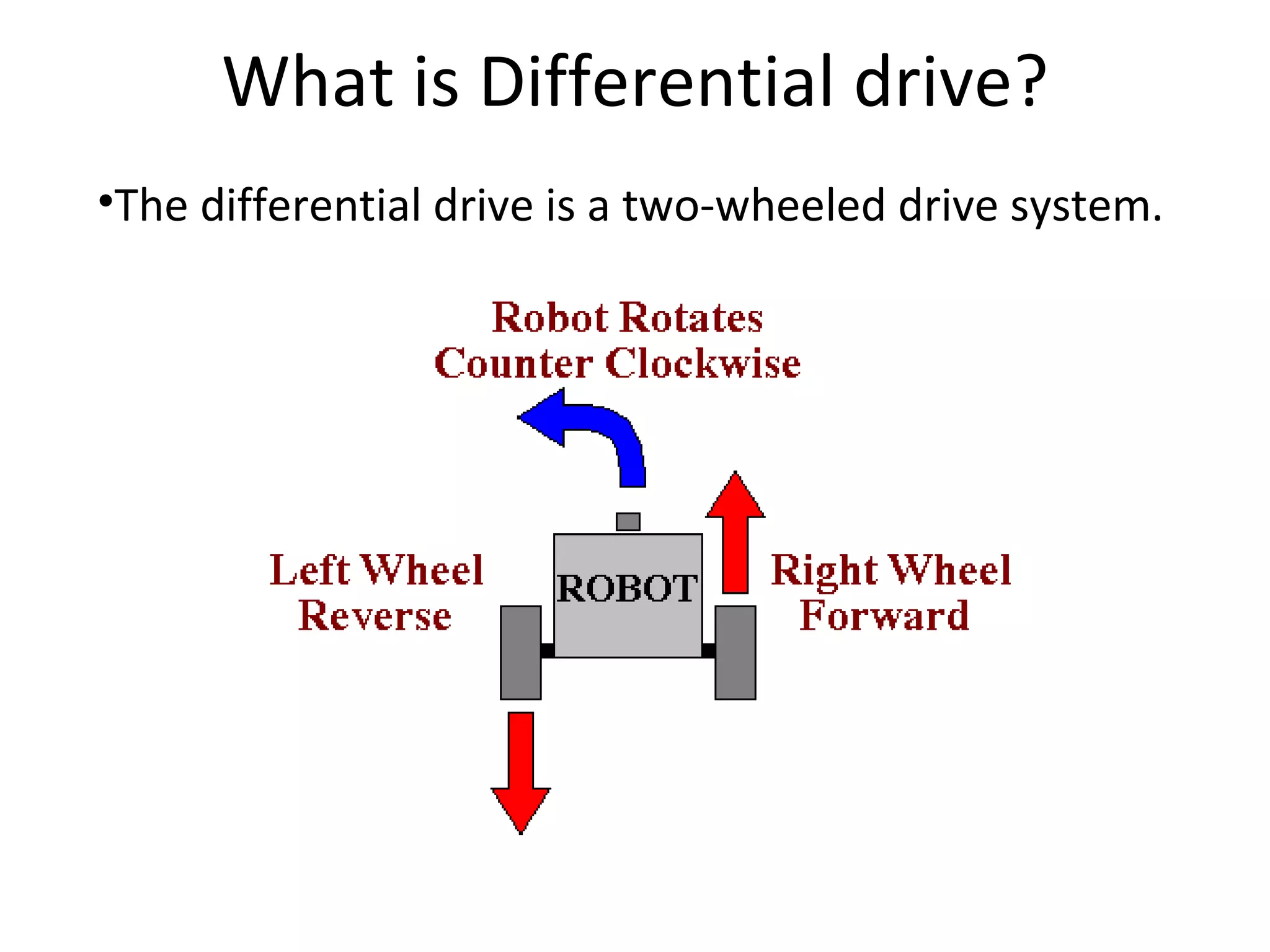

The document describes the design of an electronics and programming project for a minor project involving an Atmega32 microcontroller, H-bridge circuit, DC motors, and programming in AVR Studio 4 to control the movement and direction of the motors through switches and sensors. Electronic components include an Atmega32 microcontroller, crystal oscillator, resistors, capacitors, diodes, and switches to operate the motors and LEDs according to programmed instructions loaded onto the microcontroller. The goal is to build a differentially-driven programmable robot using a basic H-bridge circuit design to reverse the polarity of the DC motors to control forward and backward movement.