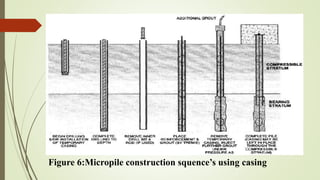

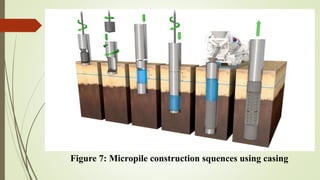

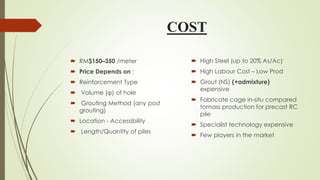

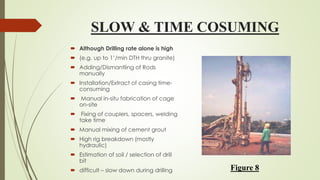

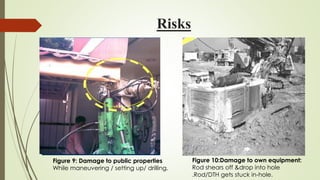

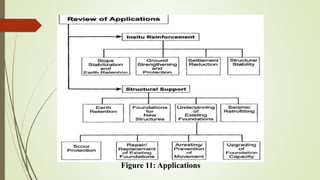

The document discusses micropiles and provides information on their history, classifications, construction sequences, advantages, disadvantages, applications, and challenges. Micropiles were first introduced in the 1950s in Italy and have since been used widely in Europe and the US. They are small-diameter piles that are drilled and grouted, and can withstand axial and/or lateral loads. Key challenges with micropiles include their relatively high cost compared to other foundation techniques, the time-consuming nature of the construction process, and risks associated with the drilling and installation work.