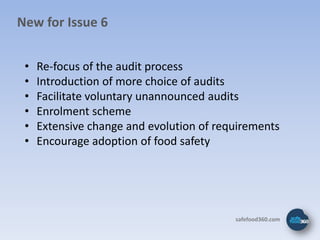

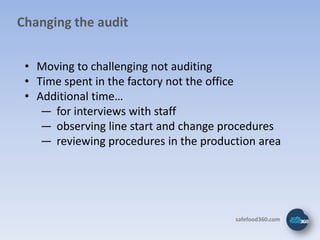

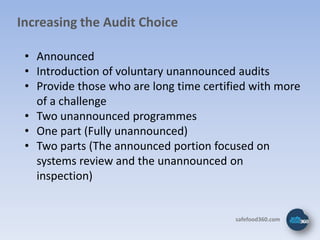

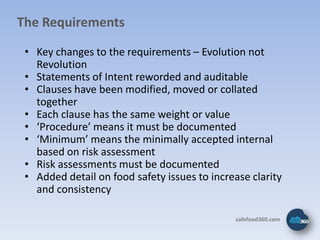

The document provides an overview of changes to the BRC Global Standard for Food Safety from Issue 5 to Issue 6. Key changes include a re-focus of the audit process, more choice in audit options including voluntary unannounced audits, enrollment schemes for developing sites, extensive changes and evolution of requirements, and increased focus on areas like supplier management, allergens, and food safety. The overview discusses the reasons for changes, highlights of new and modified requirements, and how sites can prepare for the new Issue 6 standard.