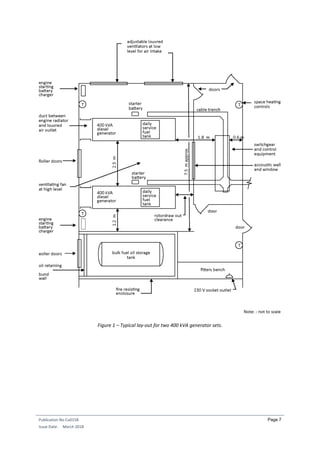

This document provides a comprehensive overview of generator sets (gensets) used for medium to long-term backup power, highlighting their critical applications in facilities like hospitals and data centers. It discusses their main components, types, sizing considerations, and the importance of maintenance and noise abatement to ensure system reliability and compliance with local regulations. The emphasis is on selecting gensets for critical loads and ensuring system availability during utility failures.