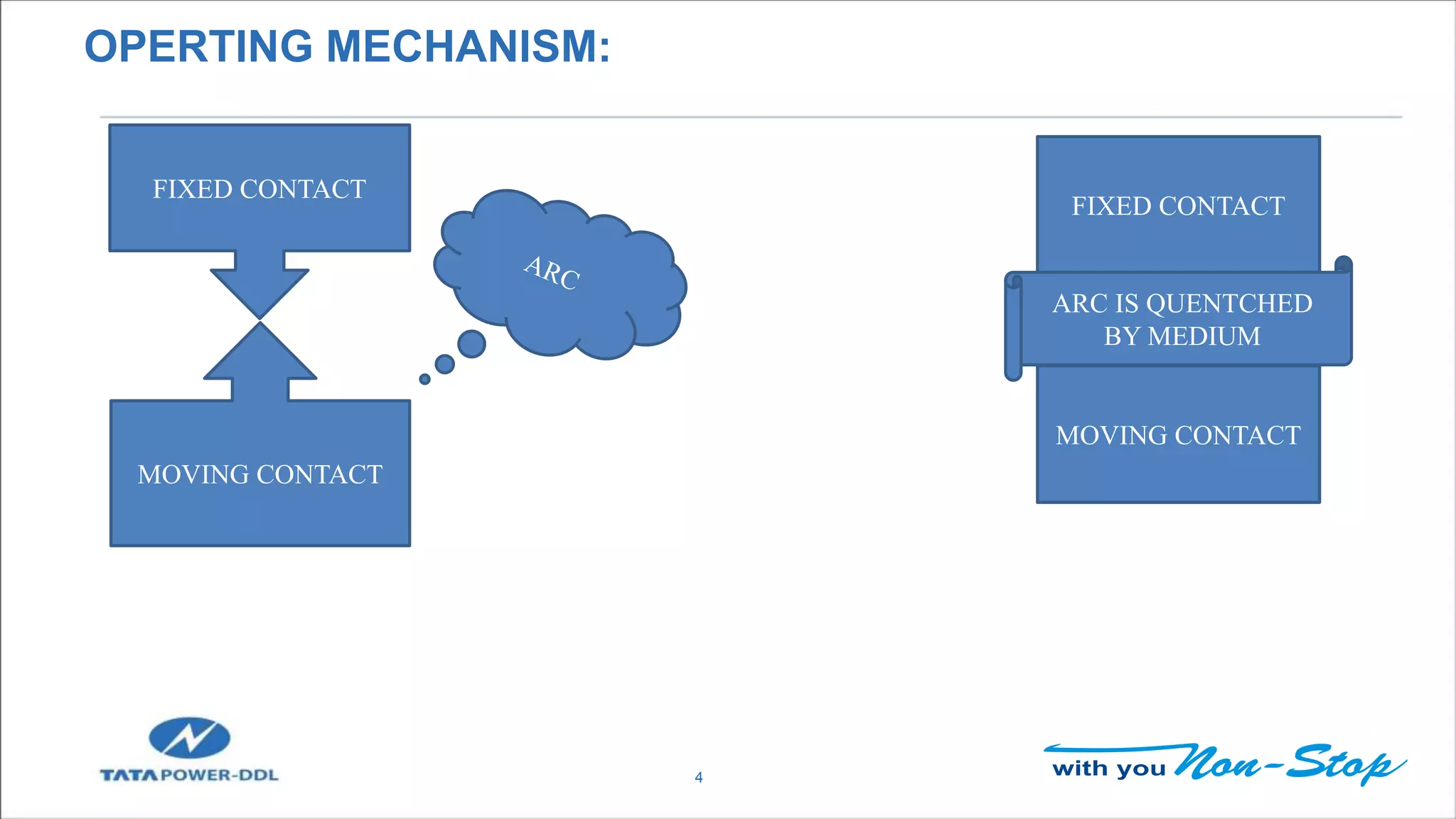

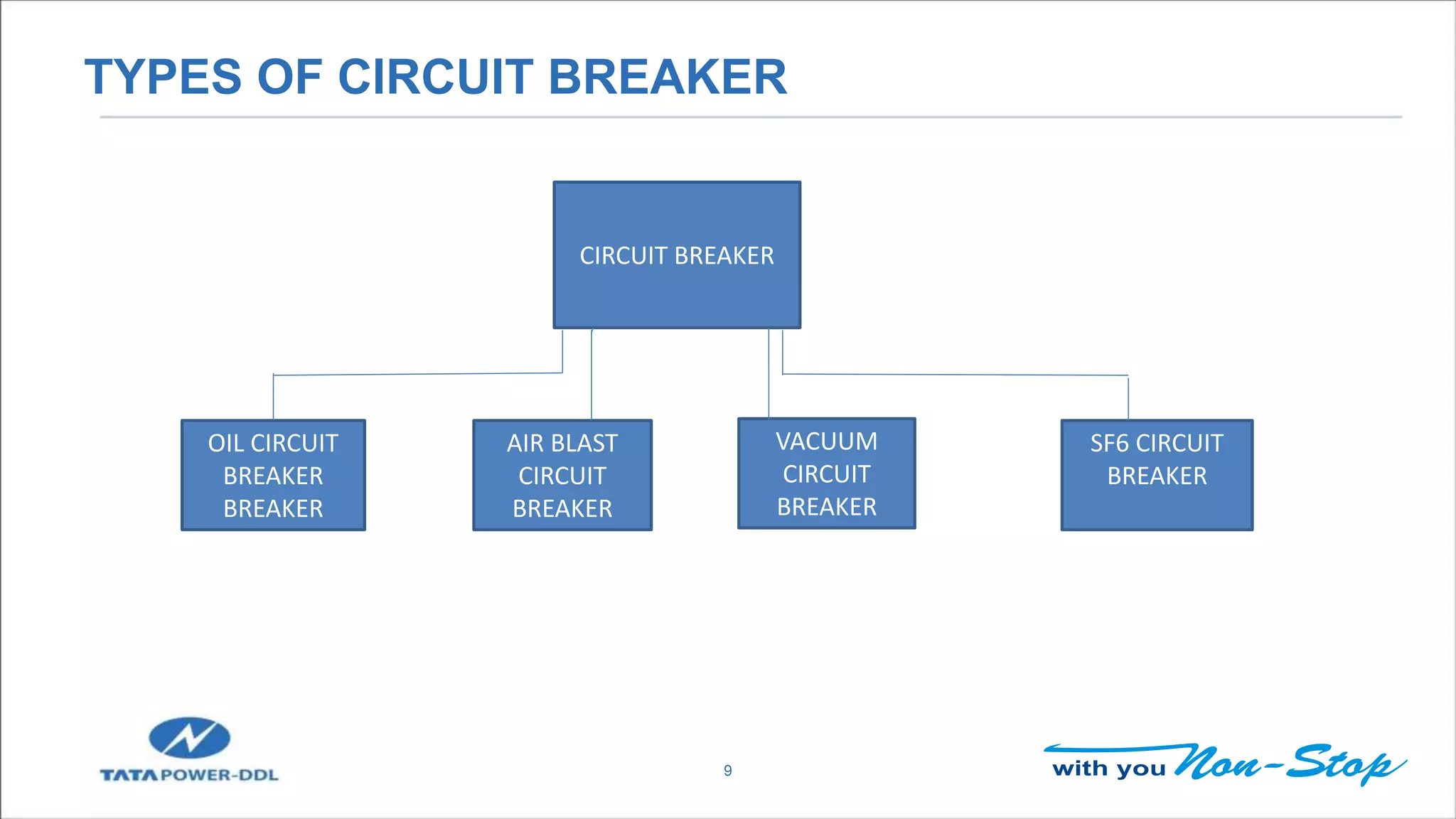

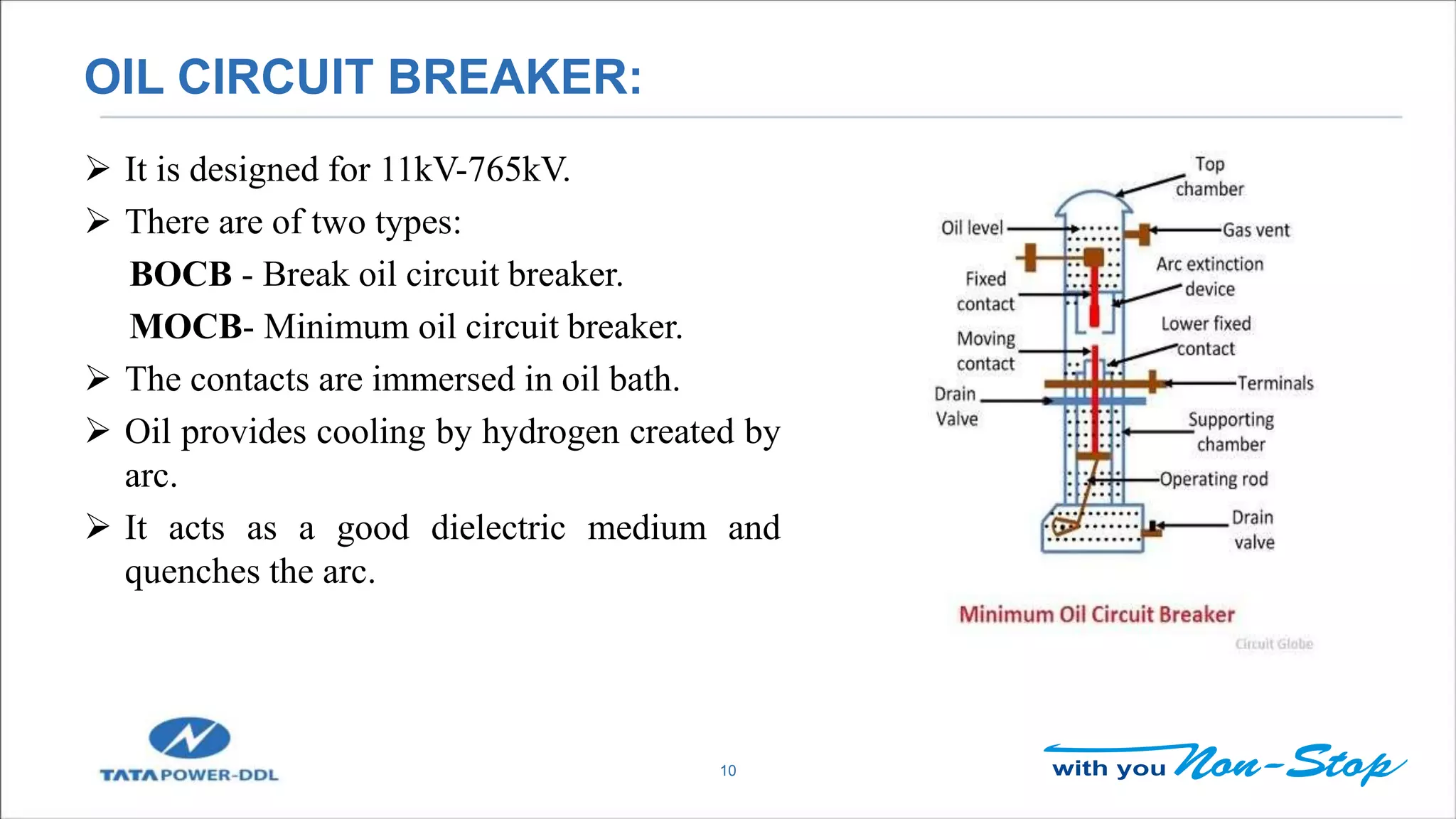

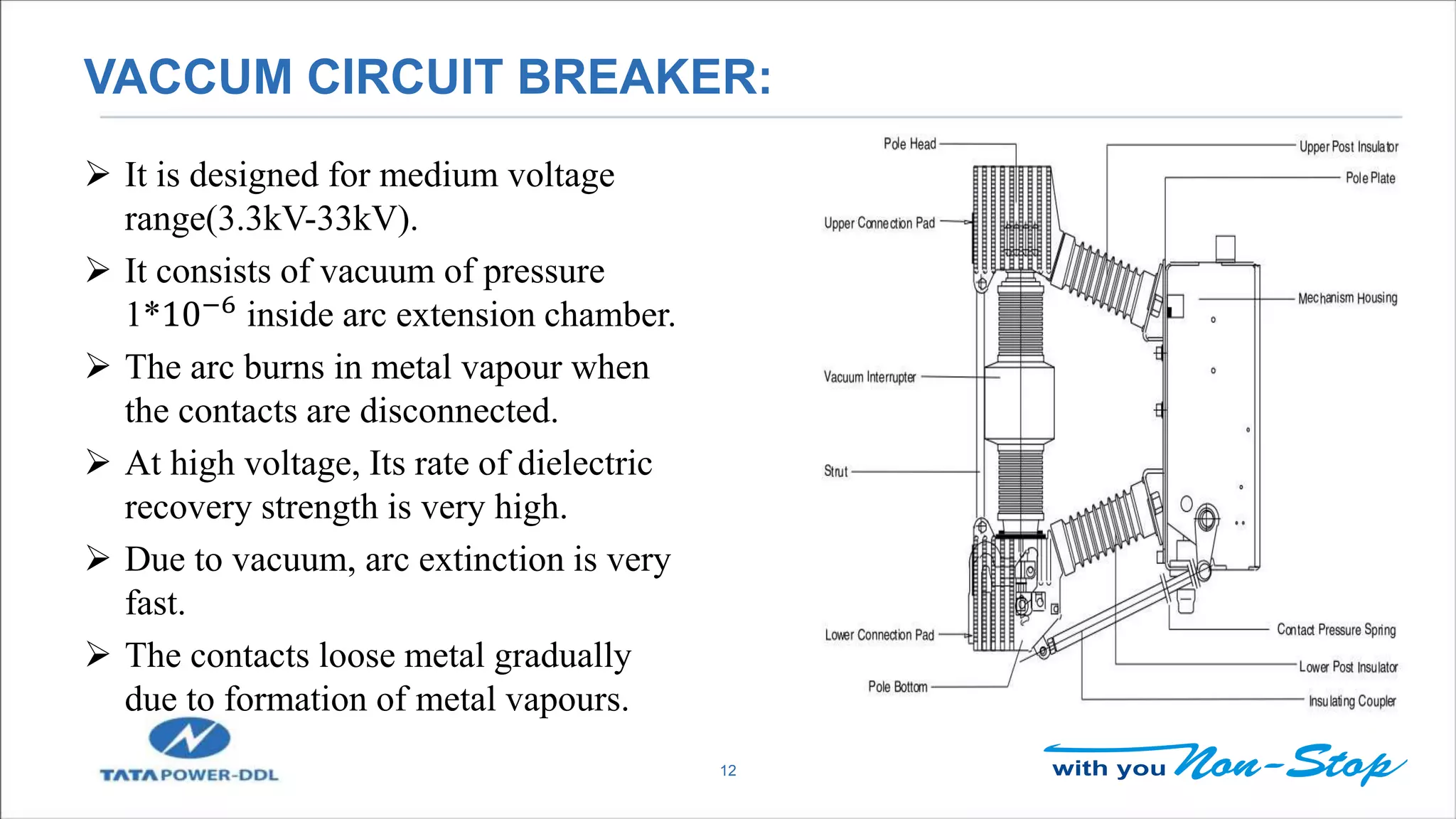

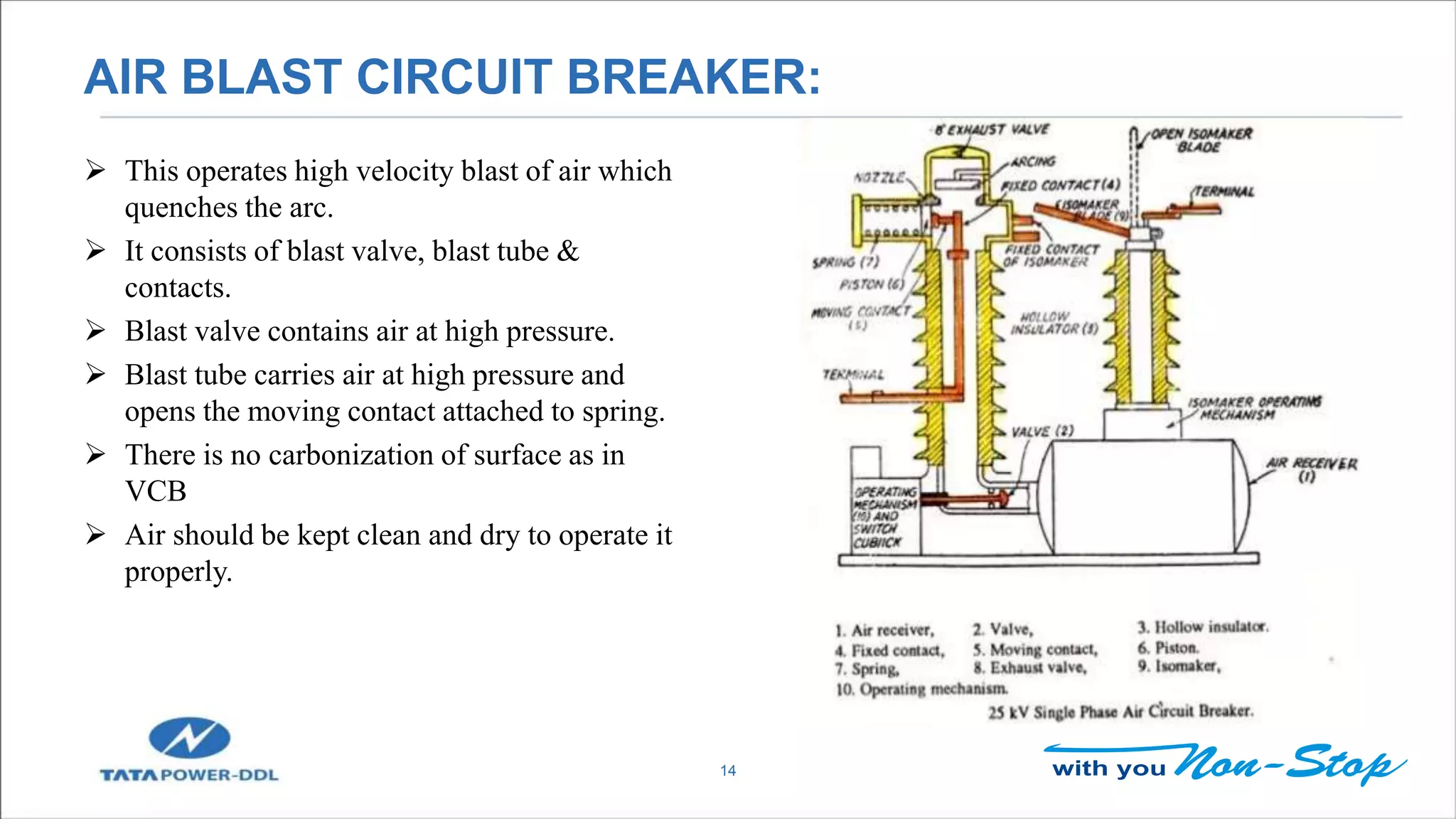

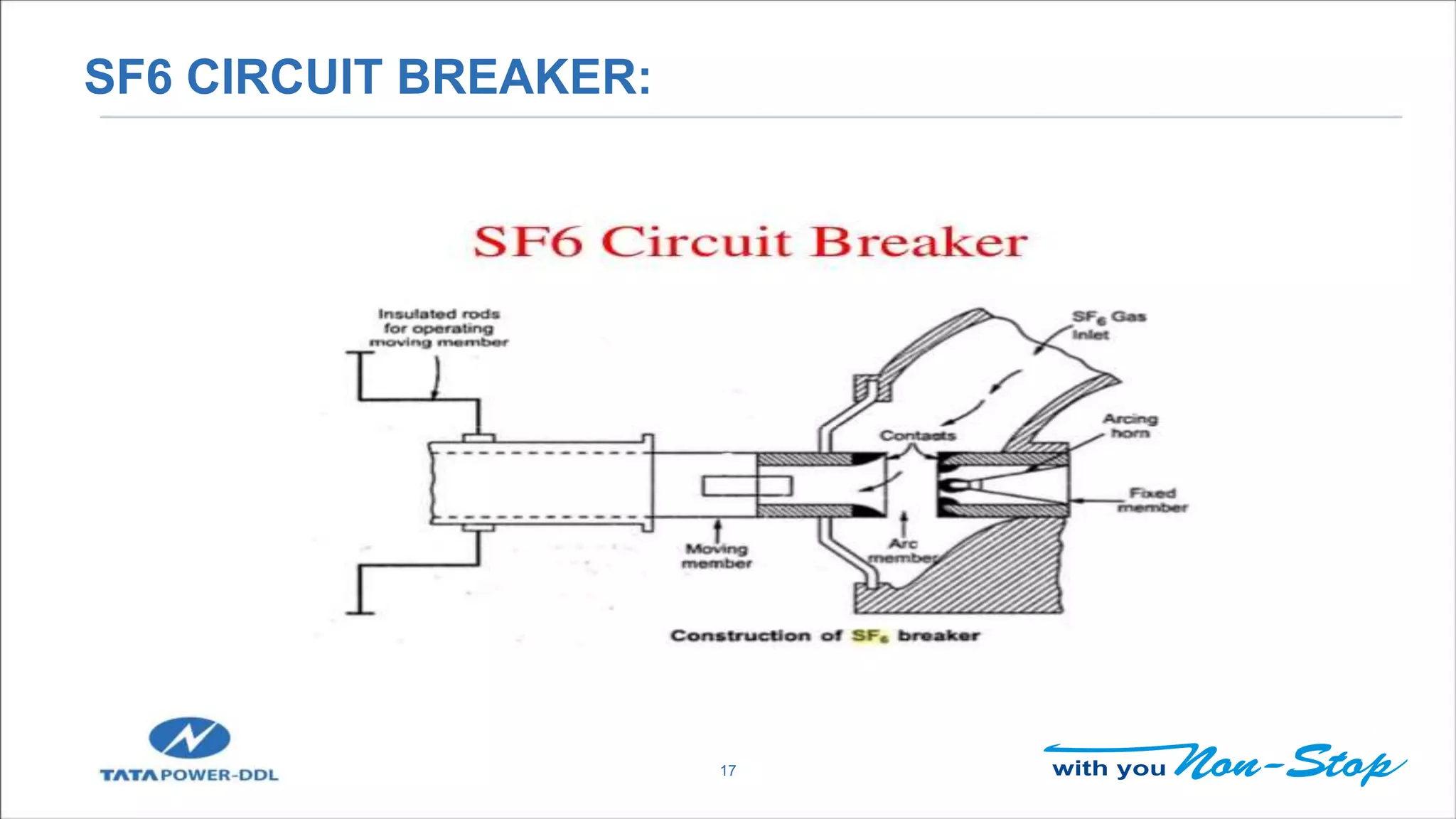

The document provides an overview of high voltage circuit breakers, including their introduction, operating mechanisms, and different types such as oil circuit breakers, vacuum circuit breakers, air blast circuit breakers, and SF6 circuit breakers. It details the functions, advantages, and disadvantages of each type, emphasizing the importance of these devices in protecting electrical networks and identifying faults. The conclusion highlights the growing popularity of vacuum and SF6 circuit breakers due to their reliability and speed.