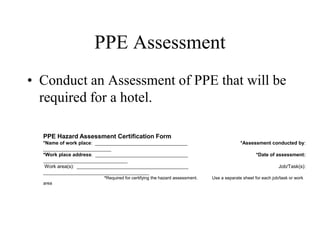

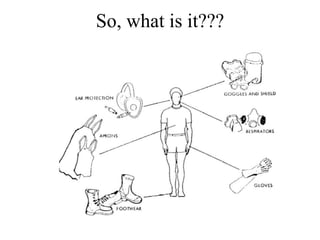

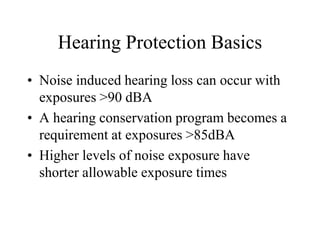

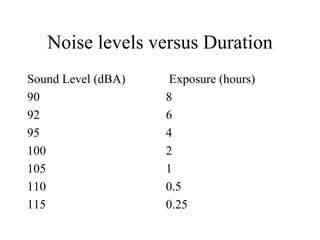

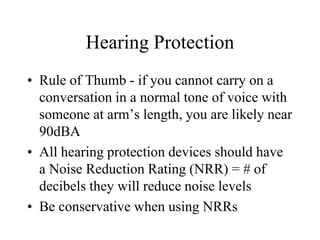

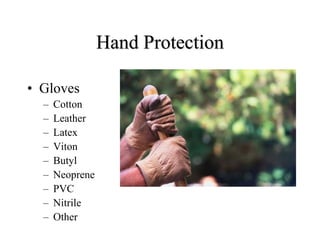

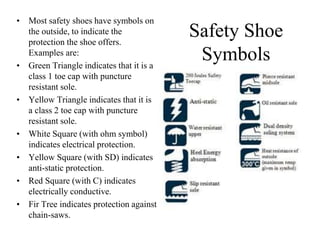

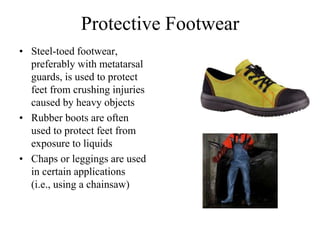

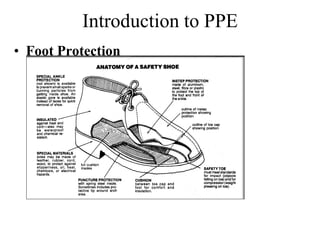

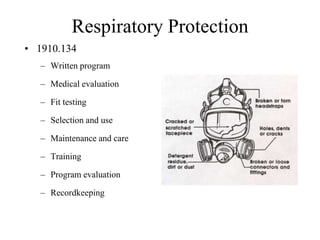

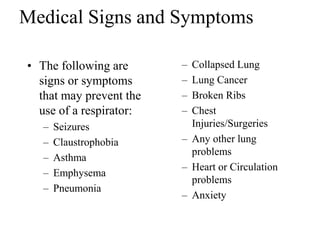

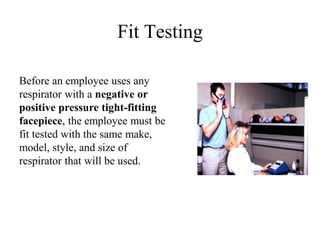

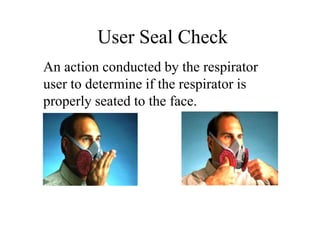

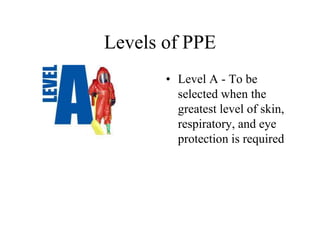

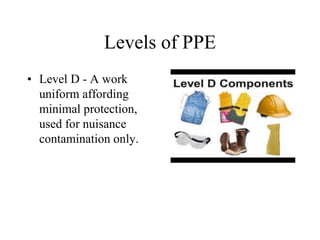

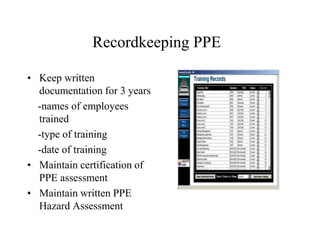

This document discusses personal protective equipment (PPE) requirements. It begins with an overview of objectives which include reviewing general PPE provisions, hazard assessments, basic hazard categories, hazard sources, and types of PPE. It then provides details on various types of PPE like head, eye, face, hearing, hand, foot, and respiratory protection. Requirements around PPE training, fit testing, medical evaluations, and record keeping are also reviewed. The document aims to educate about proper PPE selection and use to protect workers from health and safety hazards.