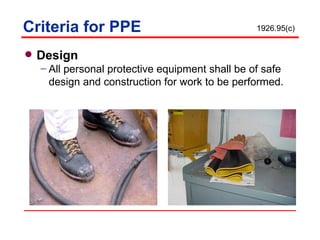

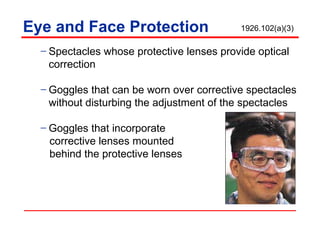

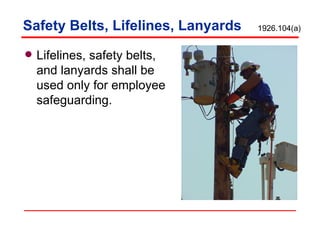

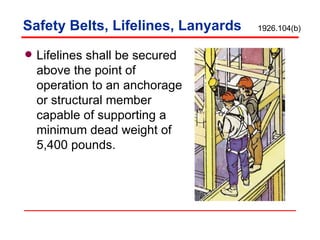

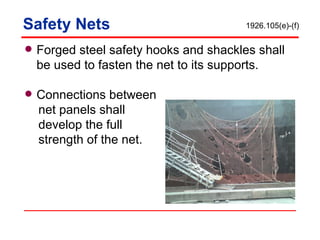

This document summarizes OSHA regulations regarding personal protective equipment in the construction industry. It discusses employer responsibilities to conduct hazard assessments, provide appropriate PPE at no cost to employees, and ensure employees are trained in the proper use of PPE. Standards are outlined for head, eye, face, foot and other protection, along with requirements for safety nets, belts, and equipment for working over or near water.