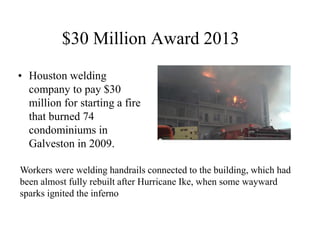

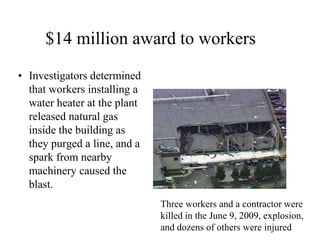

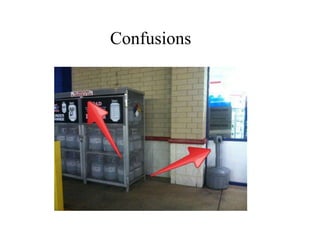

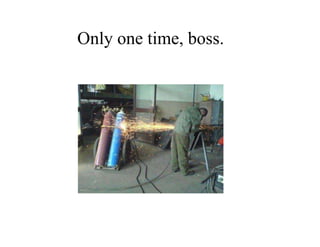

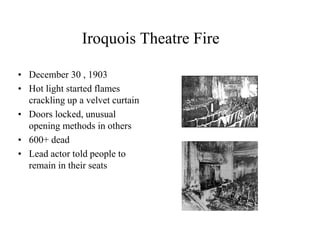

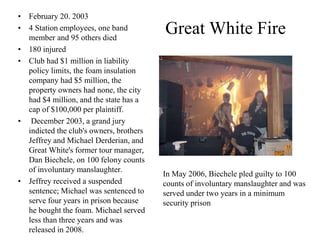

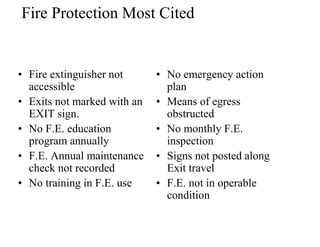

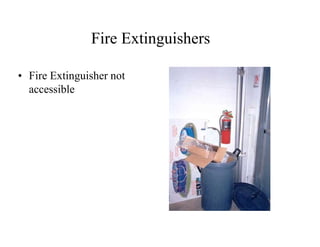

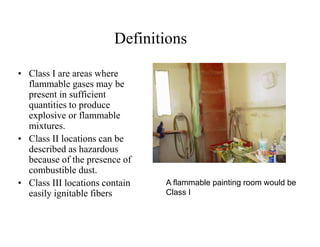

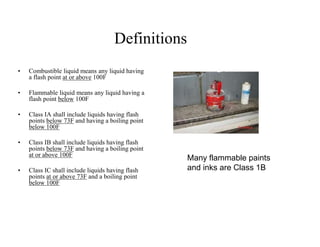

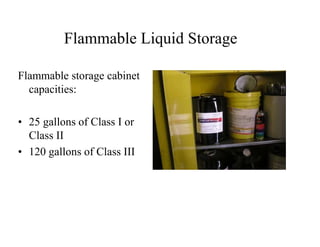

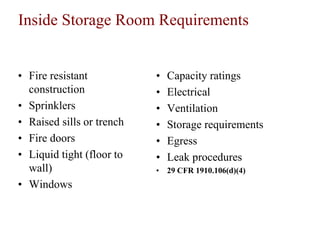

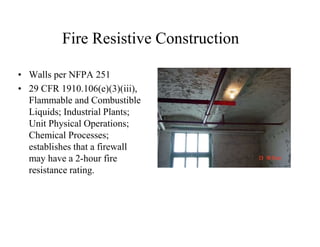

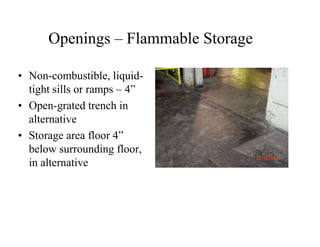

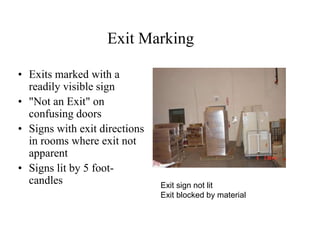

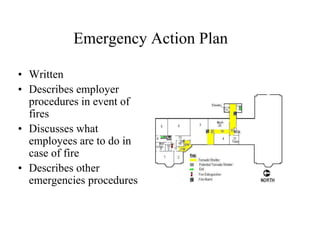

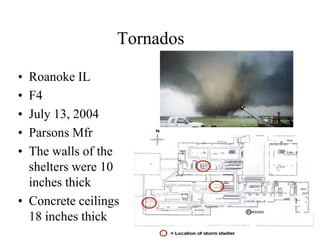

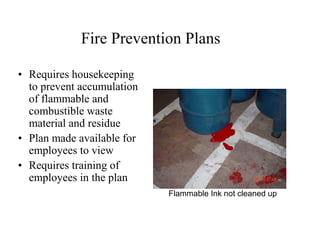

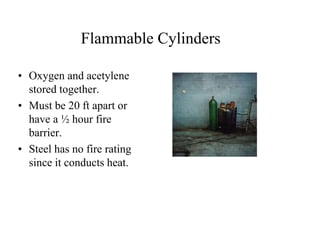

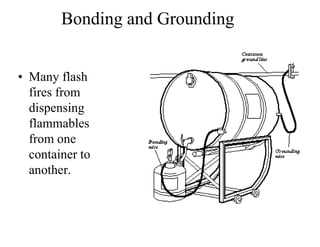

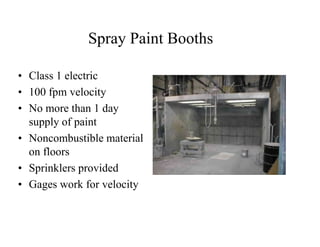

The document outlines numerous incidents related to fire safety, detailing accidents involving explosions during cutting operations and issues with fire protection regulations leading to serious injuries and fatalities. Specific cases include workers igniting flammable materials, lack of proper exits, and violations leading to significant legal penalties for companies. Recommendations for fire safety practices, such as proper storage and emergency preparedness, are provided throughout the text.