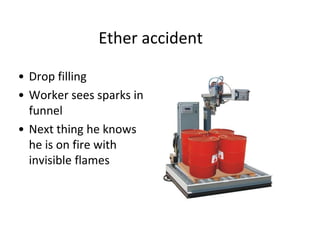

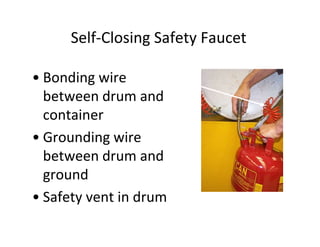

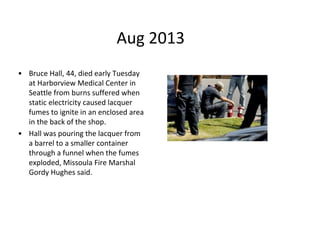

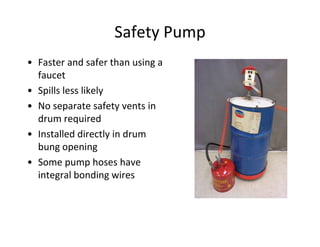

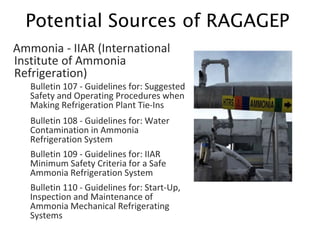

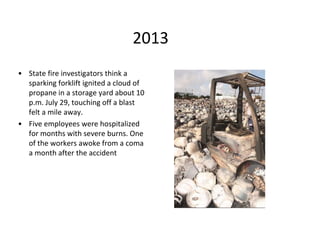

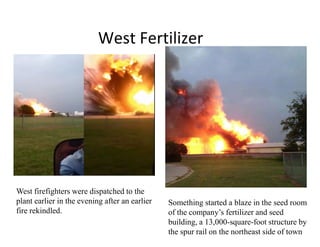

This document contains summaries of hazardous materials incidents from 1991 to 2014. It notes key details from each incident such as location, materials involved, cause of ignition, and consequences. Minimum training standards and good engineering practices are also referenced to help prevent future incidents.

![51

59

63

64

130

119(d)(3)(ii)

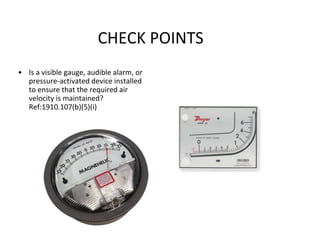

107(b)(5)(i)

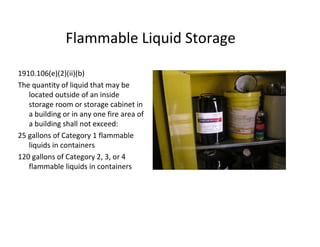

106(e)(6)(ii)

107(g)(2)

101(b)

Hazardous Materials [1910.101 –

.126]

14

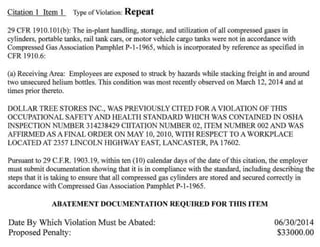

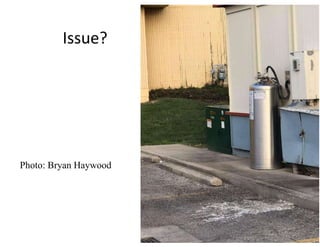

COMPRESSED GASES – HANDLING STORAGE AND USE

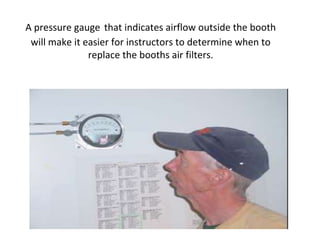

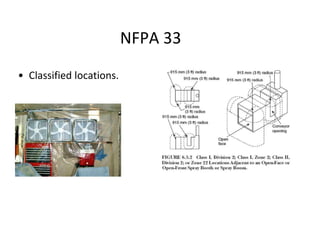

SPRAY BOOTH – AIR VELOCITY

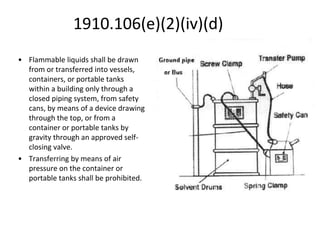

CLASS I LIQUIDS – DISPENSING

SUBPARTH

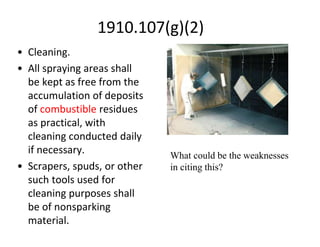

SPRAY AREAS – CLEANING WITH NON-SPARKING TOOLS

DOCUMENTATION OF EQUIPMENT WITH GOOD ENGINEERING PRACTICES](https://image.slidesharecdn.com/gi2018subparthhazardousmaterials-180506200423/85/Gi-2018-subpart-h-hazardous-materials-14-320.jpg)