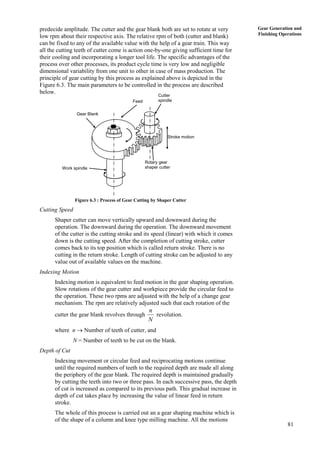

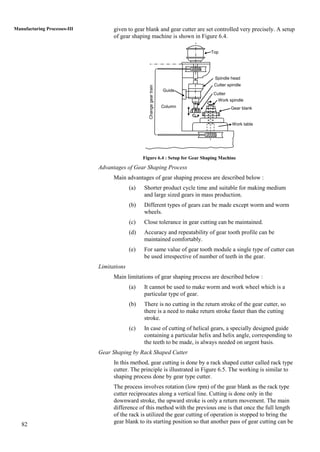

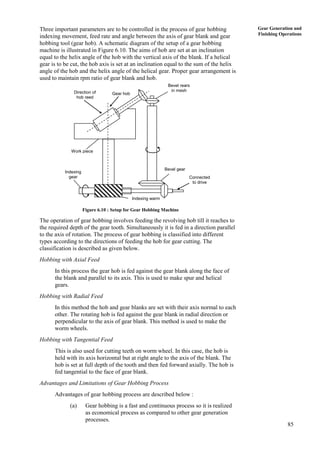

This document discusses gear generation and finishing operations. It begins by introducing gears and their uses in power transmission systems. Various gear manufacturing methods are then described, including casting, plastic molding, and machining. Gear shaping is discussed as a machining method, where a multi-point cutting tool is used to cut gear teeth into a gear blank. Key parameters for gear shaping like cutting speed and indexing motion are also outlined.