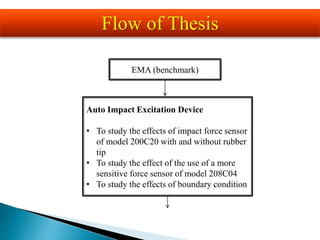

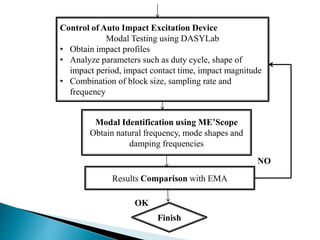

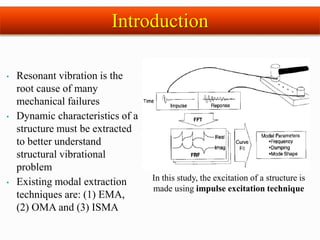

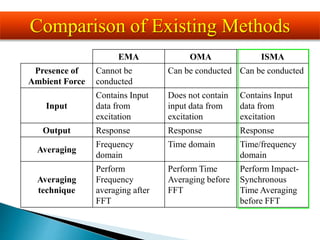

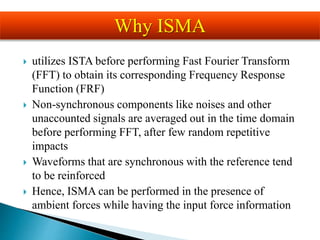

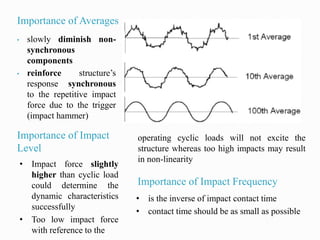

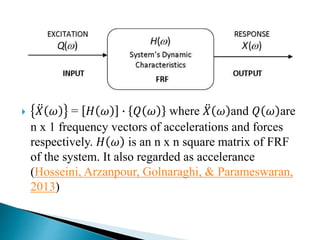

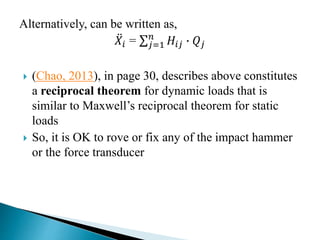

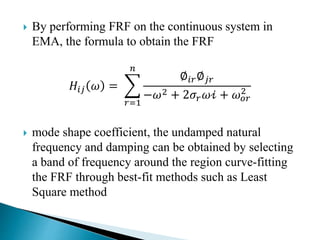

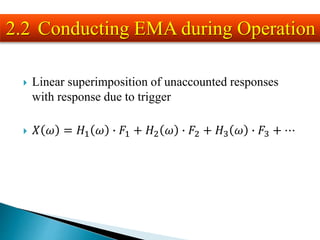

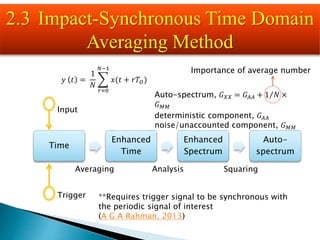

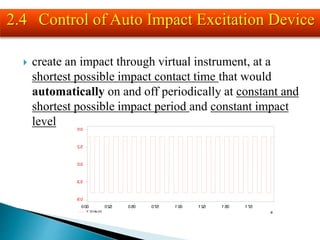

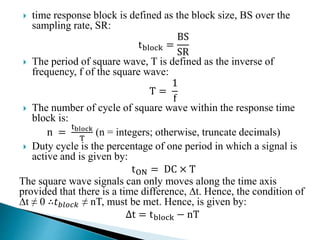

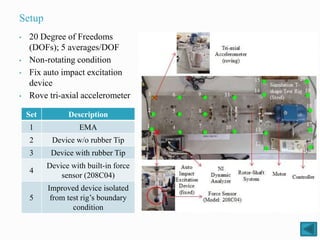

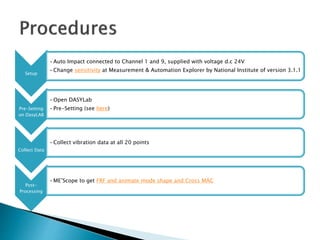

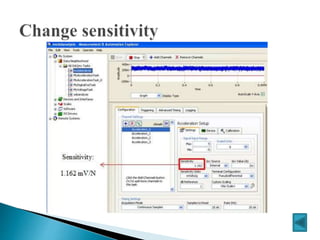

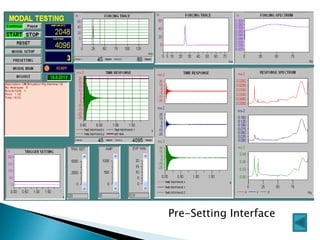

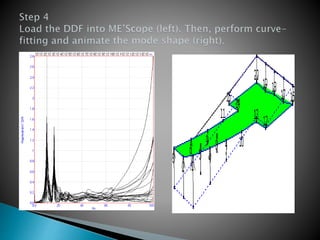

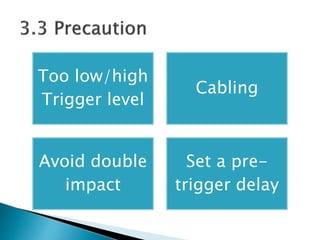

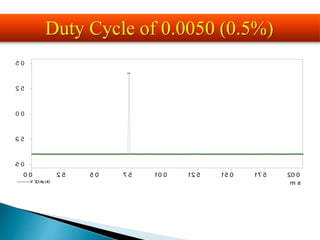

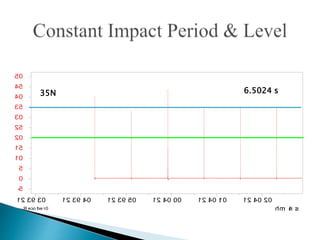

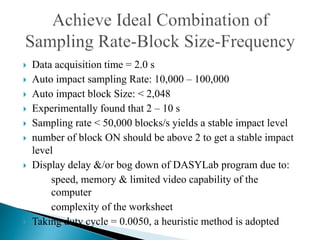

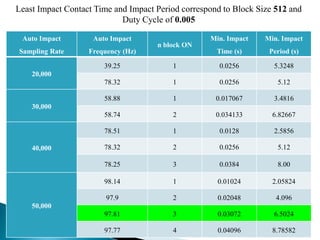

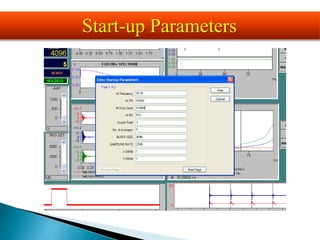

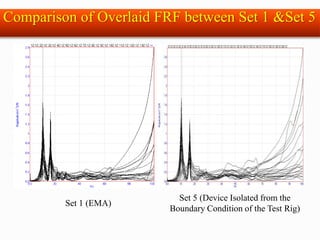

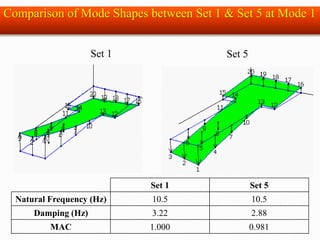

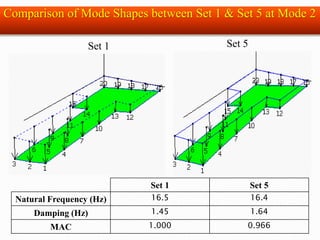

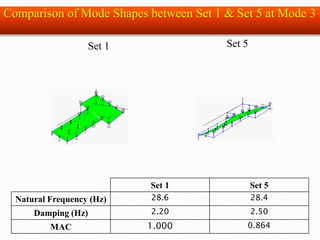

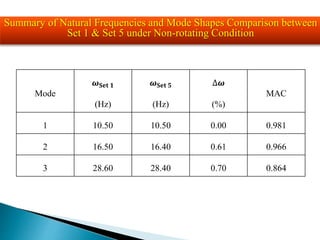

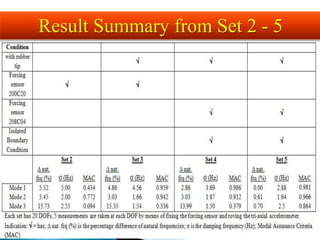

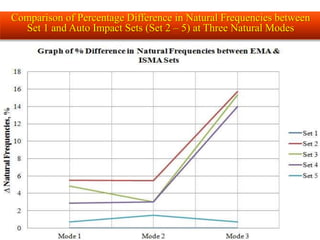

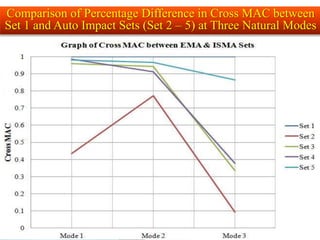

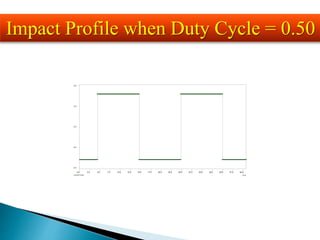

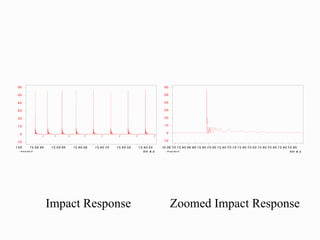

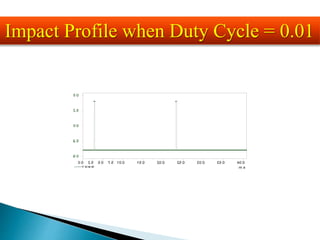

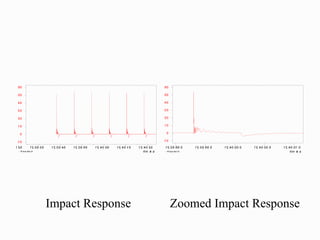

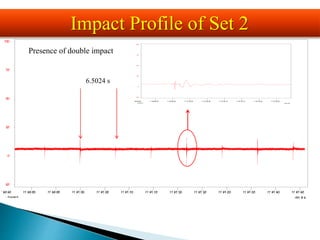

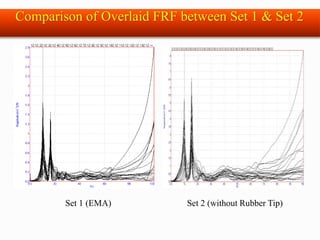

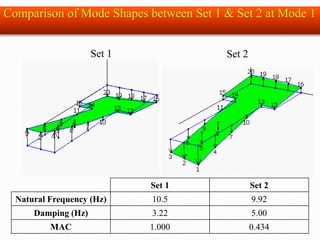

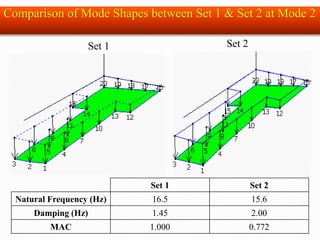

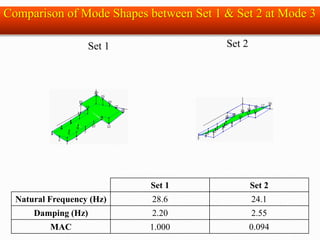

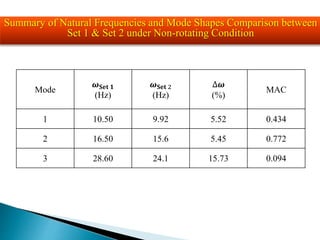

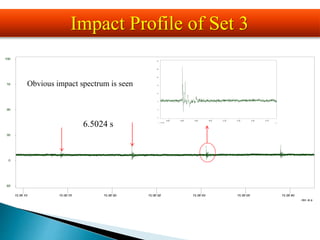

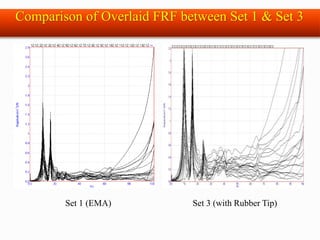

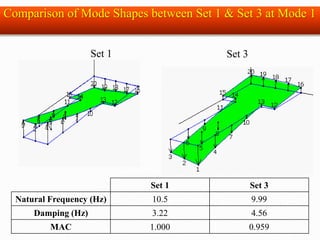

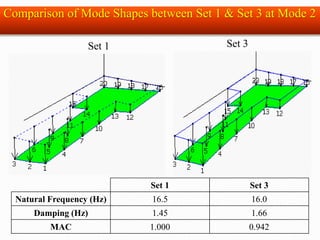

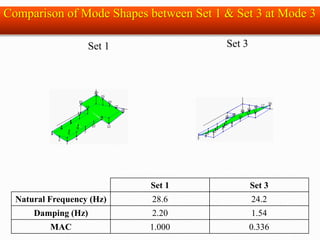

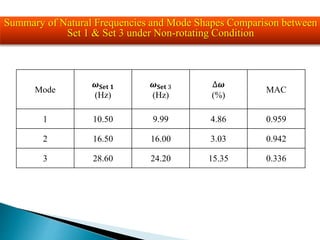

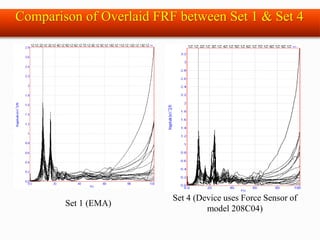

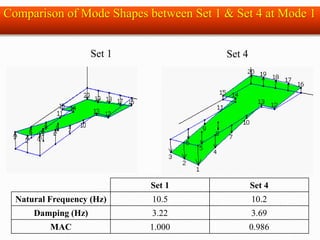

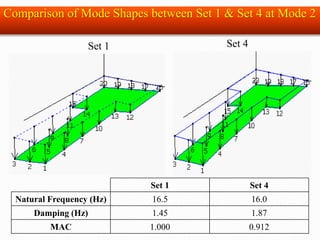

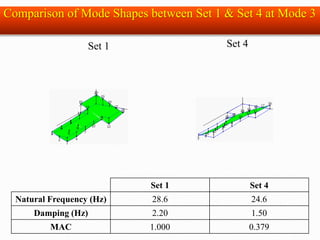

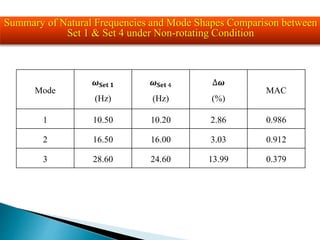

The document discusses the development and testing of an automated impact excitation device for modal analysis, focusing on the use of impulse excitation techniques to obtain dynamic characteristics of structures. It compares the effectiveness of Enhanced Impact Synchronous Modal Analysis (ISMA) against traditional Experimental Modal Analysis (EMA) under various conditions, emphasizing the automation's ability to deliver consistent impact levels and minimize labor. The study concludes that the automated device, particularly when equipped with a high-sensitivity force sensor and rubber tip, yields results comparable to benchmark EMA methods.