1) The document provides an overview and objectives of a training package on fluid mechanics and flow through pipes for engineering students.

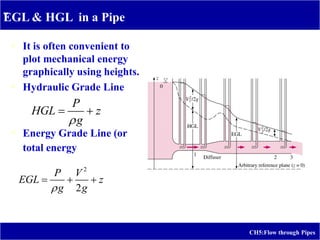

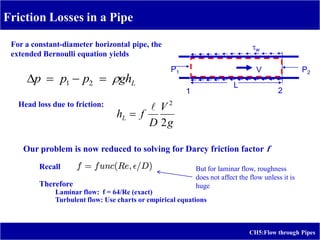

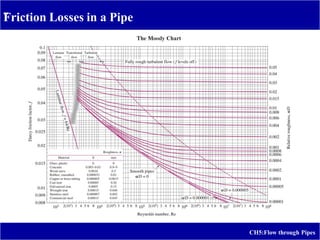

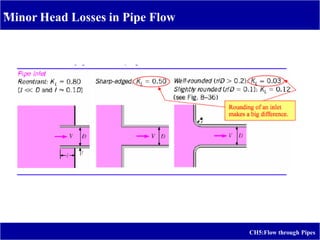

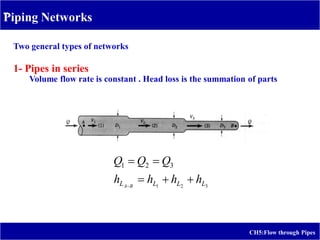

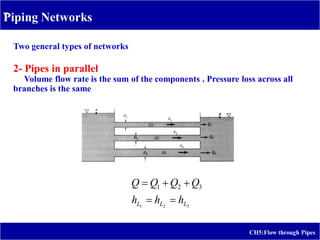

2) It includes the Bernoulli equation, energy grade line, hydraulic grade line, friction losses, minor losses, and piping networks.

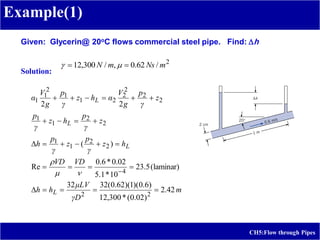

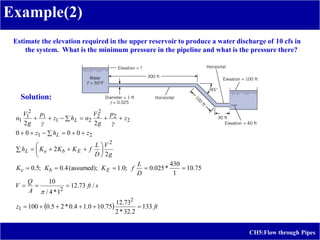

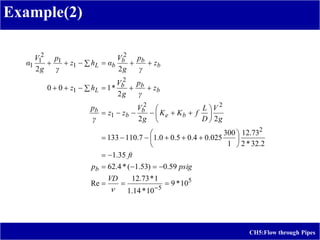

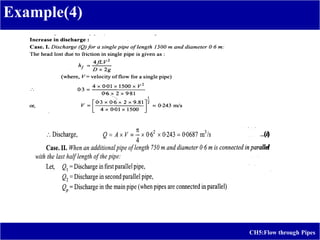

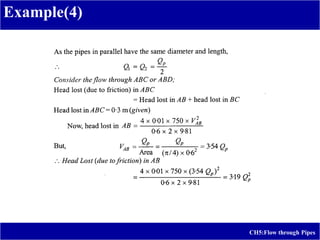

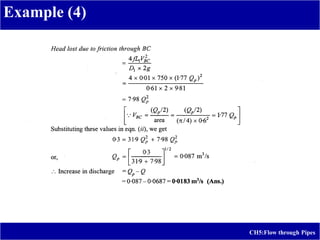

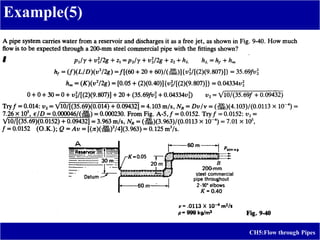

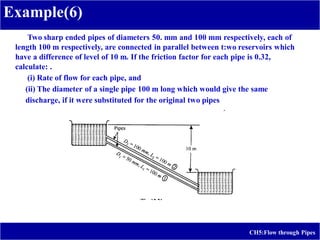

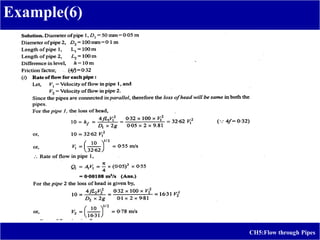

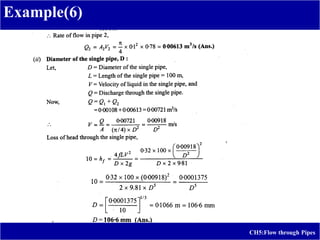

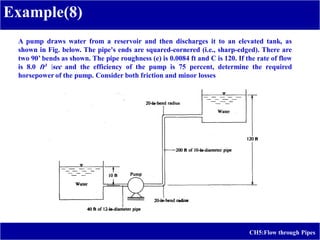

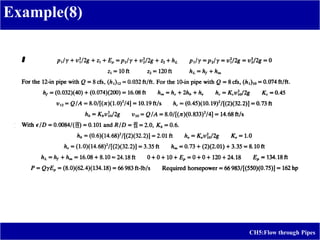

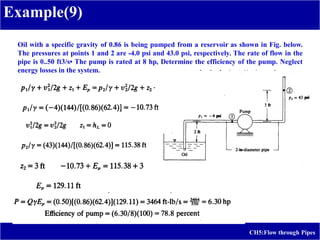

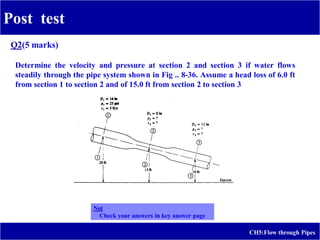

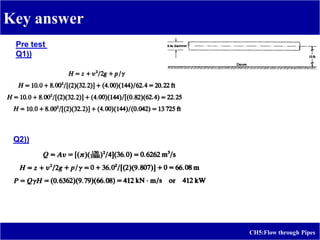

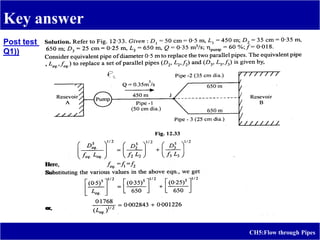

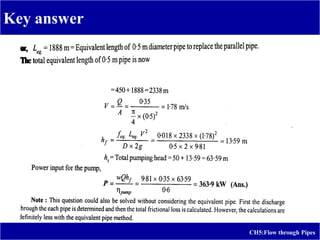

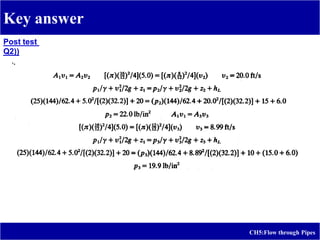

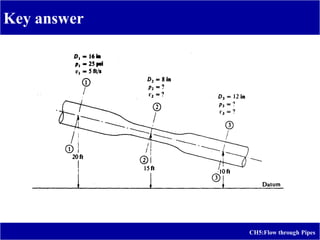

3) Example problems are provided to calculate head loss due to friction in laminar flow and estimate the elevation and pressures required for a given water discharge rate in a pipeline system.

![CH5:Flow through Pipes

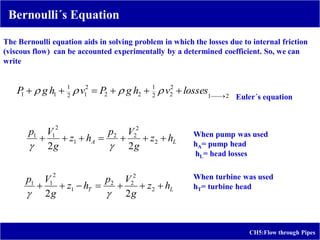

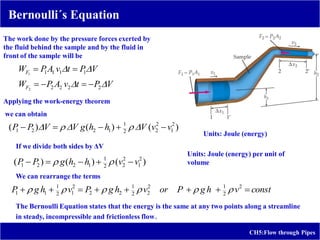

Bernoulli´s Equation

Consider a fluid flowing in a tube as shown in the figure

in a steady, incompressible, no viscous flow. We apply

the work-energy theorem to a sample of fluid initially

contained between point 1 and 2. During time Δt this

sample moves along the tube to the region between

points 1´and 2´. So,

Wall forces = ΔK [Change of kinetic Energy]

Wall forces include gravitational and pressure forces. We

neglecting internal frictional forces. Non-viscous flow.

No mechanical dissipation energy is considered.

Work of gravitational forces can be computed as the

variation of potential energy of sample. Considering the

continuity equation we can obtain

Change of kinetic energy of sample will be

Fluid moving in a pipe that varies in both height and

cross-sectional area. The net effect on the sample

during a time Δt is that a mass initially at height h1 and

speed v1 is transferred to a height h2 with speed v2

)

(

)

(

)

( 2

1

2

1 h

h

V

g

h

h

g

m

U

)

(

)

)(

( 2

1

2

2

2

1

2

1

2

2

2

1

v

v

V

v

v

m

K

](https://image.slidesharecdn.com/ch5flowthroughpipes-210407121102/85/Flow-through-pipes-8-320.jpg)

![CH5:Flow through Pipes

Bernoulli´s Equation

const

v

h

g

P

v

h

g

P

v

h

g

P

2

2

1

2

2

2

1

2

2

2

1

2

1

1

1

Remarks about Bernoulli Equation

g

v

h

g

P

const

g

v

h

g

P

2

2

2

2

2

Flow work or pressure energy; Is the portion of the potential energy term

that the fluid is capable of yielding of its sustained pressure. IS Unit: Joule

per Newton (meter). Dimension : Length

(1)

(2)

Potential energy, due to the gravitational field. IS Unit: meter

Each term having the same units (1) [Energy per unit

of volume] (2) [Energy per unit of weight].

Expression (1) can also be considered as energy per

volume flow rate, and (2) as energy per weight flow

rate

Kinetic energy. IS Unit: meter (Joule per Newton)](https://image.slidesharecdn.com/ch5flowthroughpipes-210407121102/85/Flow-through-pipes-10-320.jpg)