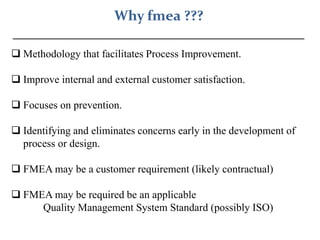

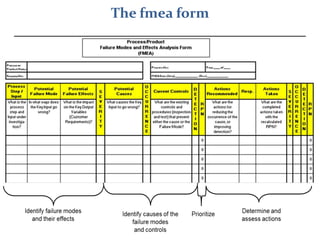

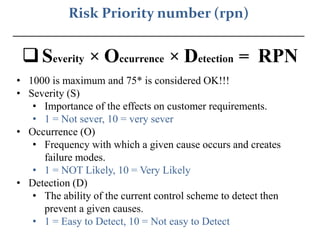

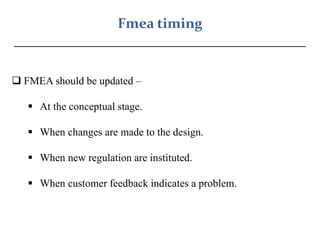

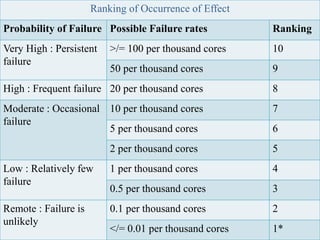

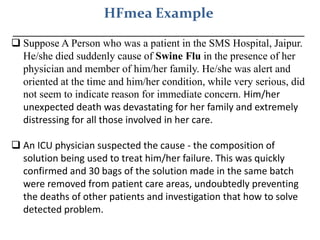

This document provides an overview of Failure Mode and Effect Analysis (FMEA). FMEA is a systematic method to identify and prevent product and process failures before they occur. It involves reviewing components and processes to understand potential failures, effects, and causes. Key steps include determining severity, occurrence, detection ratings and calculating a Risk Priority Number. FMEA is widely used in industries like aerospace, automotive and healthcare to improve quality and safety. The document outlines the FMEA process and terms, provides examples, and discusses advantages like improved reliability and customer satisfaction.