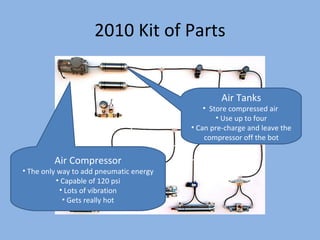

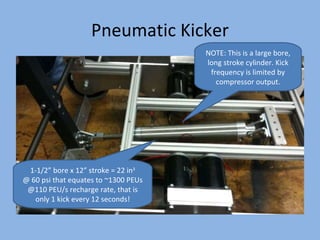

This document provides an overview of pneumatic systems for FIRST robots, including key components in the 2010 kit of parts, basic pneumatic principles, calculations for determining cylinder force, examples of typical pneumatic applications, and tips for design and safety. It covers topics such as air compressors, tanks, regulators, solenoid valves, cylinder sizing, energy usage calculations, gripper and braking system examples, and considerations around the pros and cons of pneumatics.