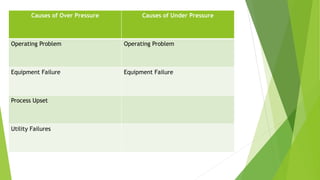

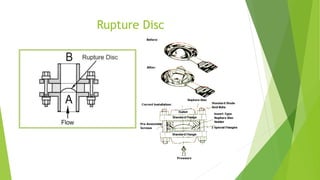

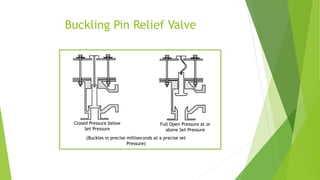

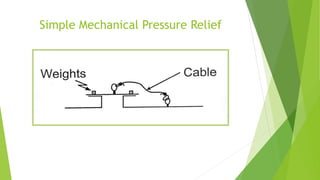

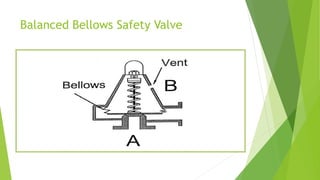

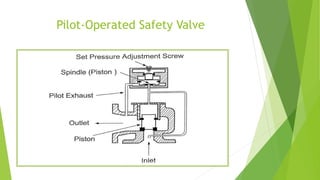

The document discusses pressure safety devices, outlining various pressure terminologies and causes of overpressure and underpressure. It details safeguards such as safety interlocks and maintenance systems, along with types of pressure relief devices and their applications. The mention of a disaster due to missing safety valves emphasizes the importance of proper safety protocols in chemical processes.