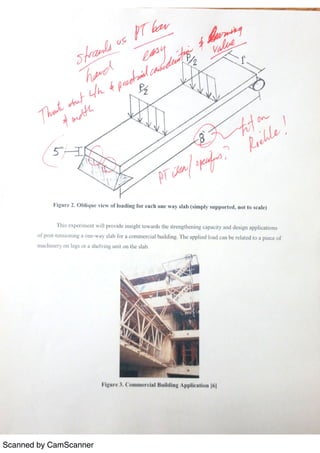

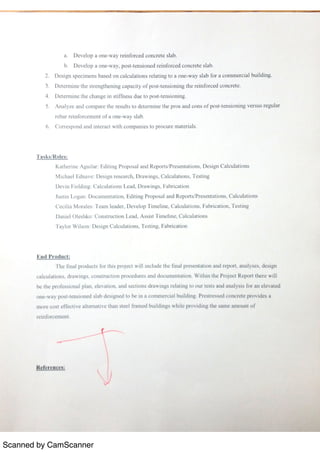

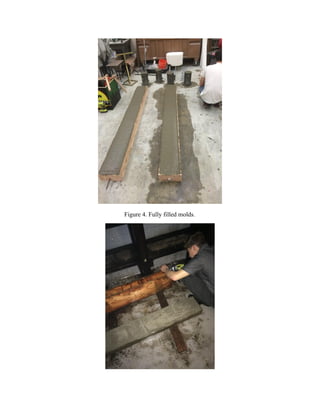

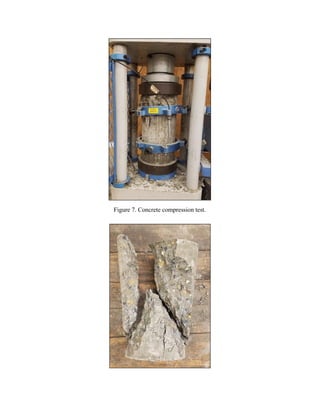

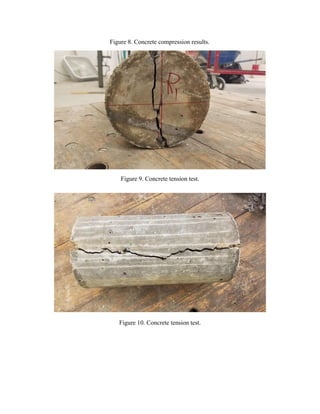

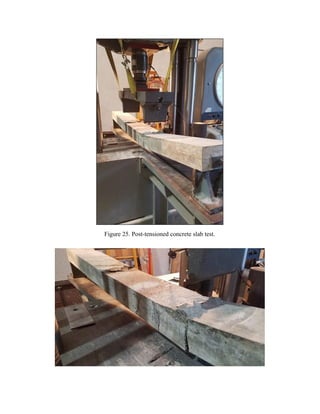

The document summarizes an experiment comparing pre-stressed/post-tensioned reinforcement to traditional steel reinforcement in concrete slabs. Two slabs were fabricated - a post-tensioned slab with 3/4" threaded rod and a rebar reinforced slab with #4 rebar. Material properties were tested, including concrete compressive strength from cylinders. The post-tensioned slab resisted 3.135 kips before cracking compared to 1.200 kips for the rebar slab. Post-tensioning doubled the load at cracking and increased ultimate strength by 1.2x. While post-tensioning increased cracking load and strength, it reduced ductility compared to the rebar slab. The results show post-tensioning can