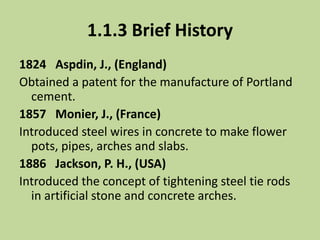

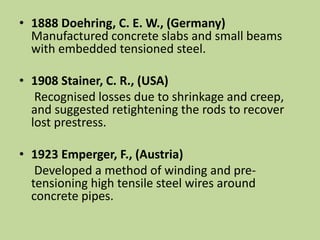

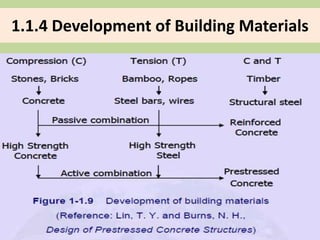

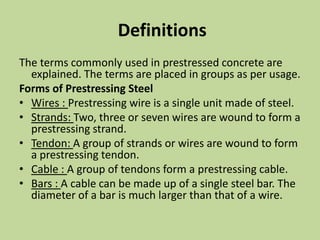

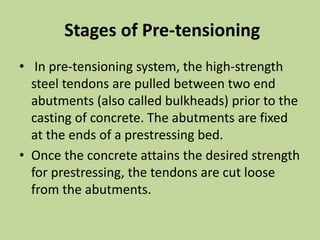

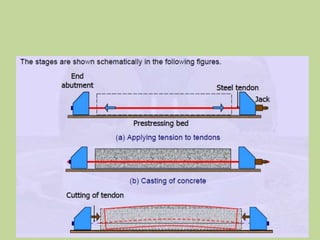

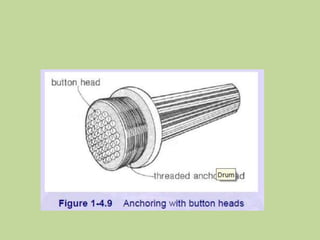

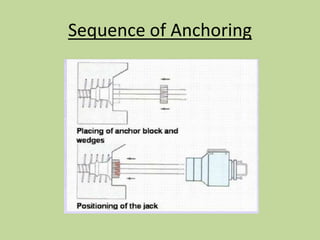

This document provides a brief history of prestressed concrete, beginning in 1824 with the development of Portland cement. It then outlines several important developments in prestressed concrete technology from the late 19th century through the mid-20th century by innovators from various countries. These include early uses of steel in concrete, prestressing methods like pre-tensioning and post-tensioning, and development of high-strength steel and anchoring systems. It also mentions increased use of prestressed concrete during World War 2 and establishment of professional organizations to support the field.