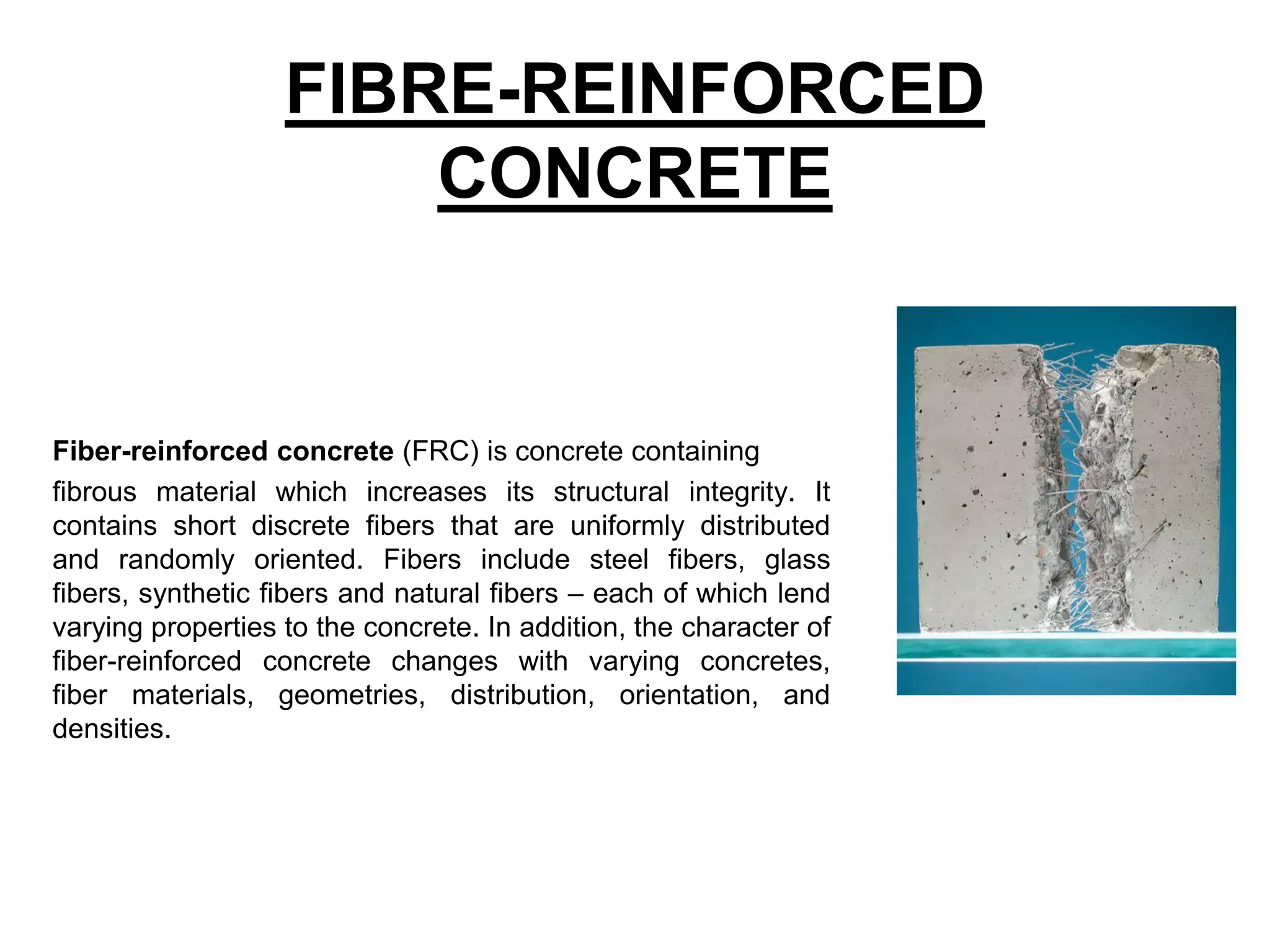

Fiber-reinforced concrete (FRC) incorporates fibrous materials to enhance structural integrity, control cracking, and improve resistance to various stresses. The composition of FRC, including fibers like steel and glass, influences properties such as tensile strength and workability, while offering advantages like reduced reliance on steel reinforcement and improved durability. Applications of FRC can be seen in various infrastructure projects worldwide, demonstrating its effectiveness in reducing self-weight and maintenance costs.