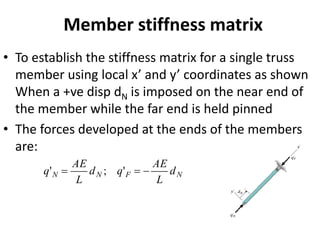

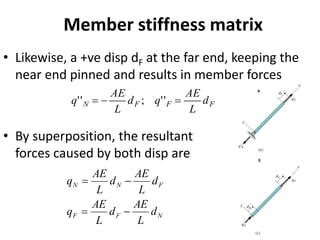

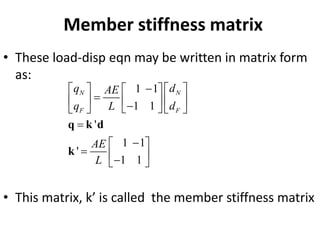

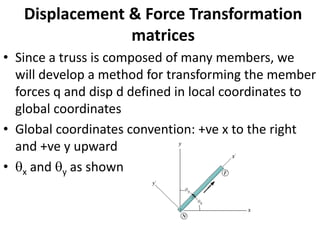

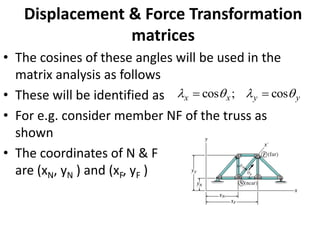

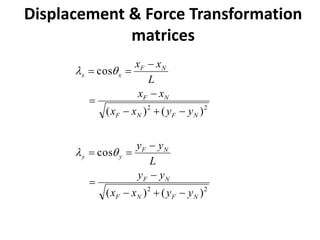

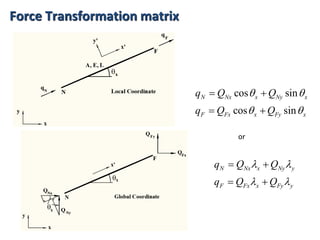

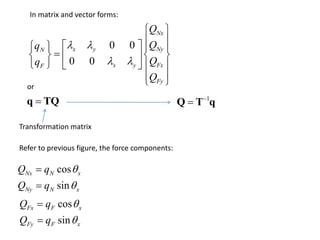

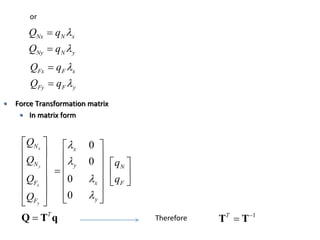

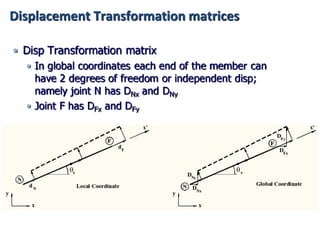

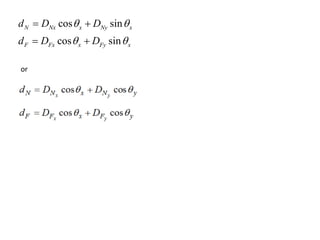

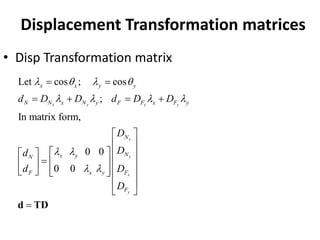

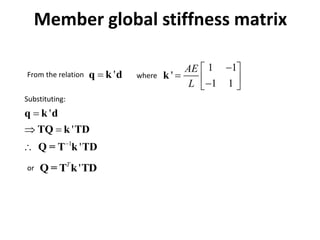

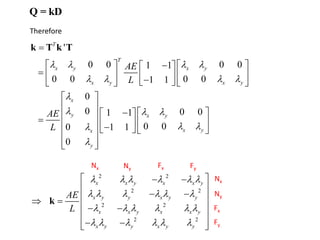

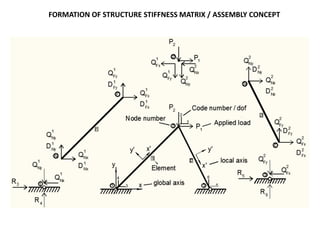

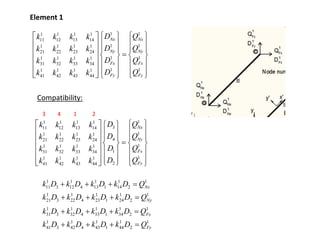

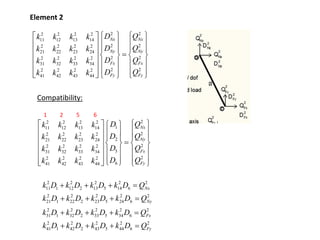

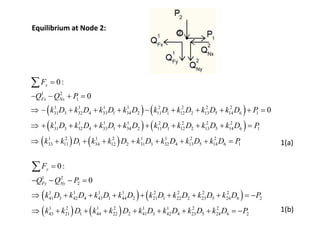

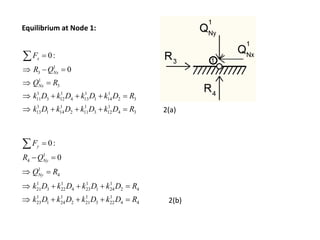

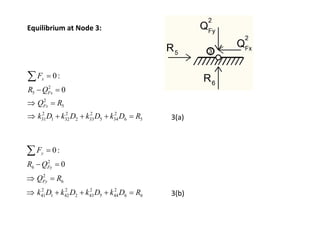

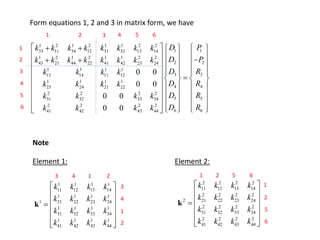

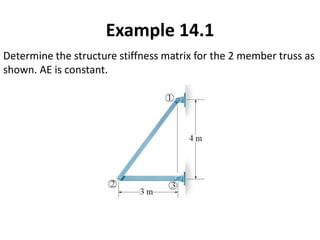

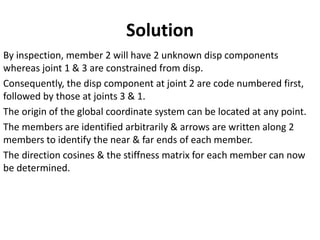

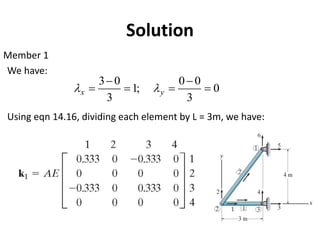

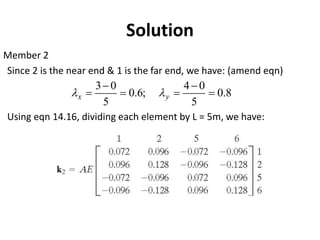

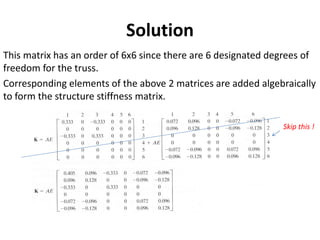

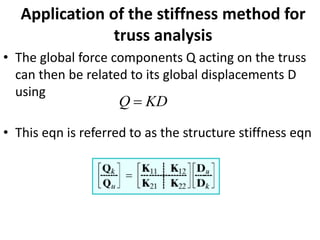

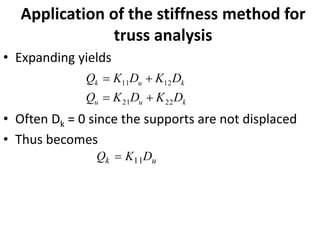

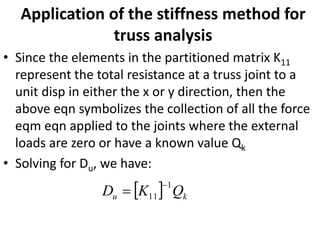

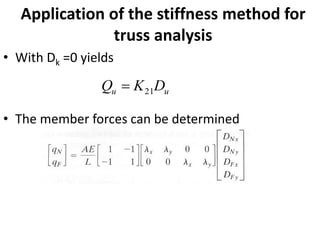

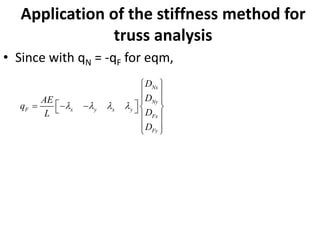

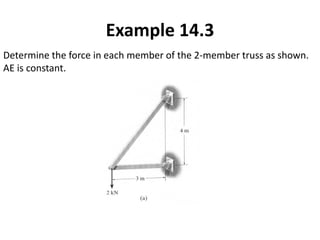

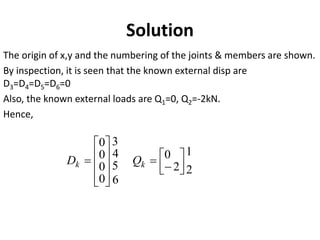

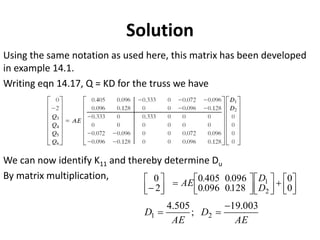

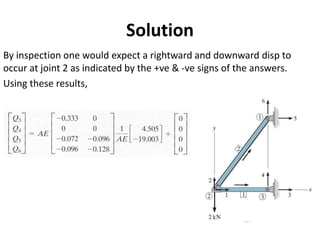

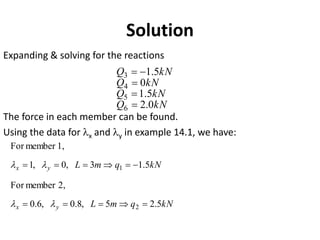

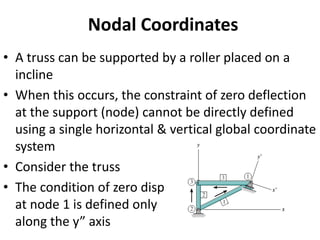

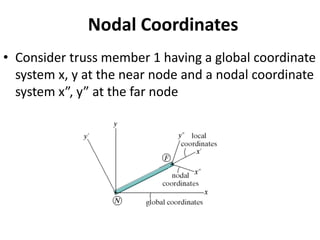

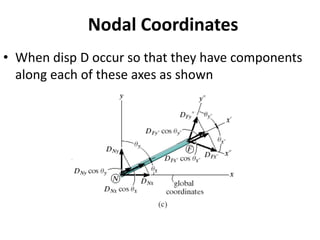

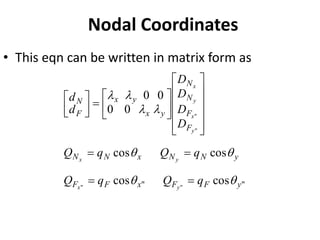

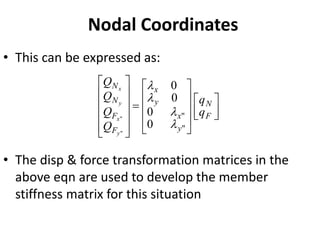

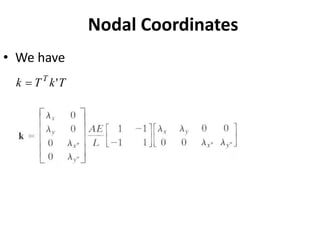

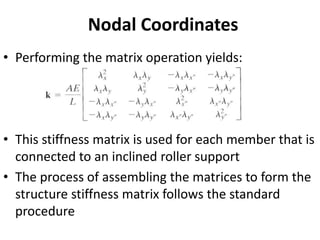

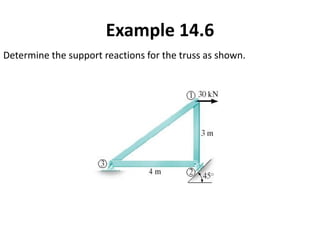

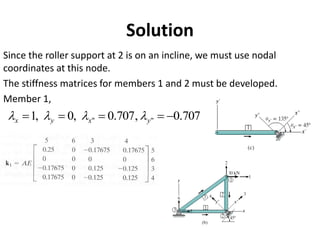

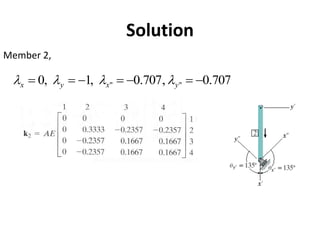

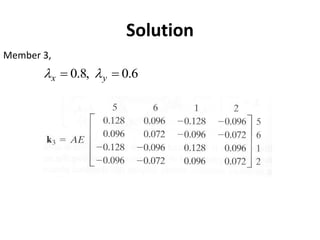

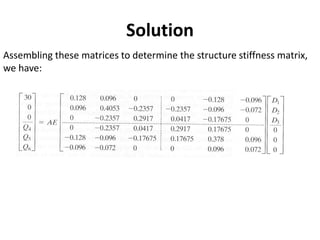

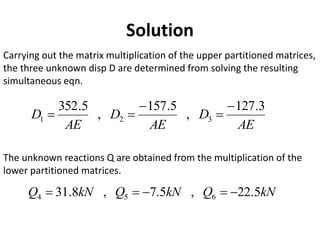

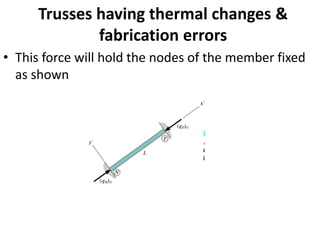

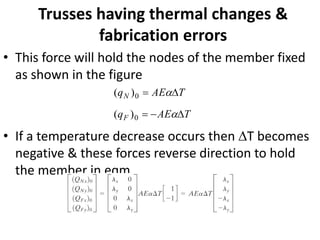

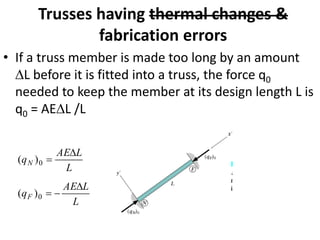

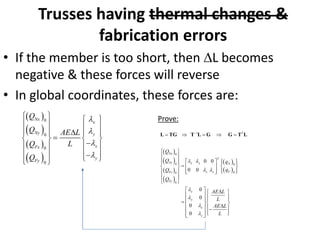

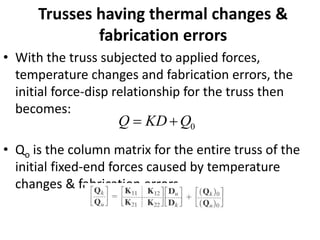

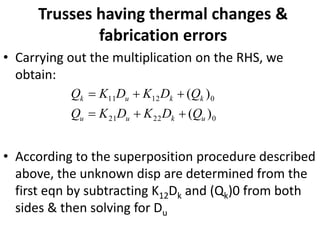

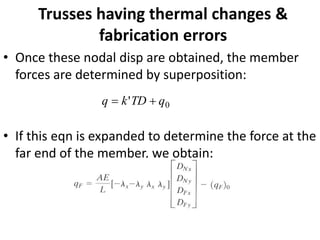

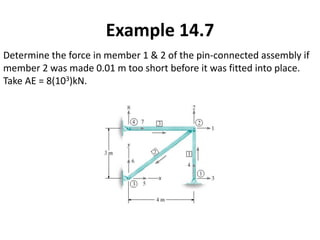

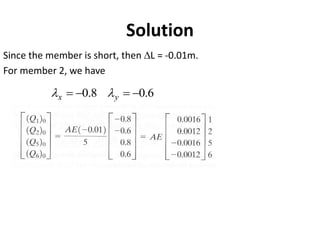

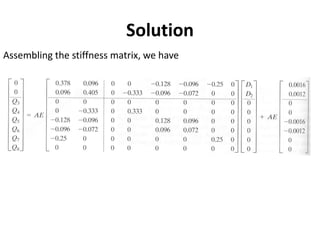

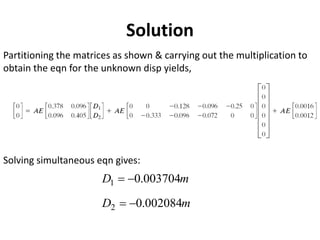

The document discusses the stiffness method for truss analysis within structural engineering, emphasizing its use for both statically determinate and indeterminate structures. It explains how to formulate stiffness matrices for individual members and assemble them into a global stiffness matrix for the entire truss. The method also includes techniques for transforming local force and displacement coordinates to global coordinates, ensuring accurate calculations of displacements and forces within the structure.