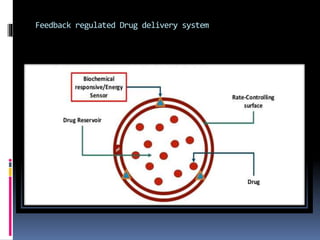

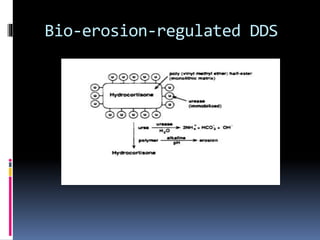

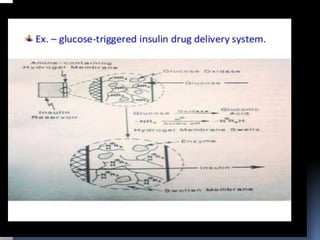

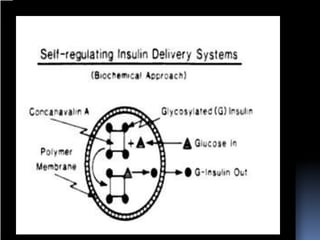

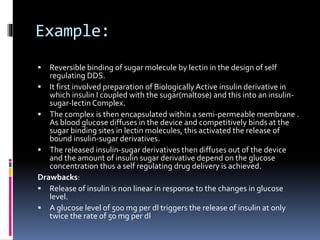

This document discusses feedback regulated drug delivery systems, which release drugs in response to physiological triggers. It provides 3 examples: 1) Bio-erosion regulated systems where an enzyme triggers polymer degradation and drug release, 2) Bio-responsive systems where a membrane permeability is controlled by biochemical triggers, and 3) Self-regulated systems using reversible binding to competitively release drugs. One approach discussed uses a cationic hydrogel to release an opioid overdose antidote in response to rising carbon dioxide levels from opioid use. Feedback systems aim to better match drug release to physiological needs compared to traditional delivery.