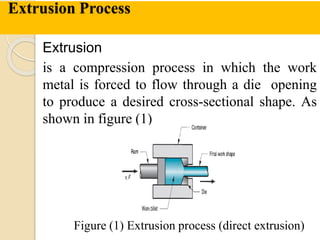

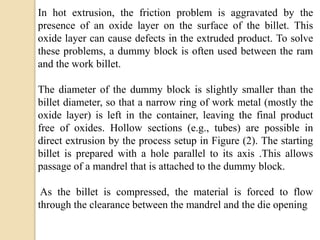

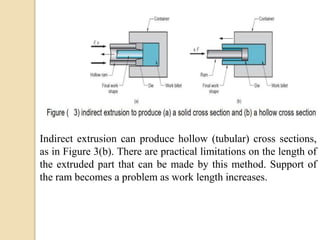

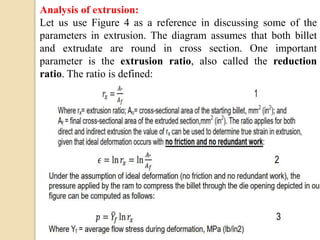

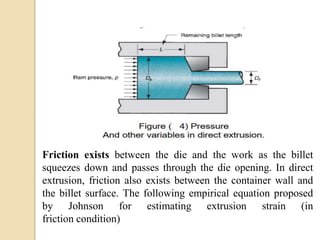

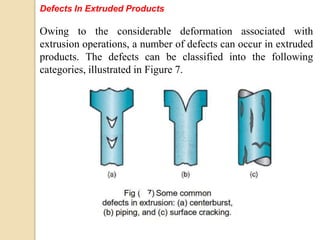

The document discusses different types of extrusion processes used to produce desired cross-sectional shapes from metal. There are several types including direct, indirect, impact, hydrostatic, hot, cold and warm extrusion. Direct extrusion involves compressing a metal billet using a ram to force it through a die, while indirect extrusion mounts the die to the ram so the material flows in the opposite direction of ram motion. Hydrostatic extrusion reduces friction by surrounding the billet with pressurized fluid. Hot extrusion softens the metal to allow more complex shapes. Defects can occur during extrusion like center bursting or surface cracking.