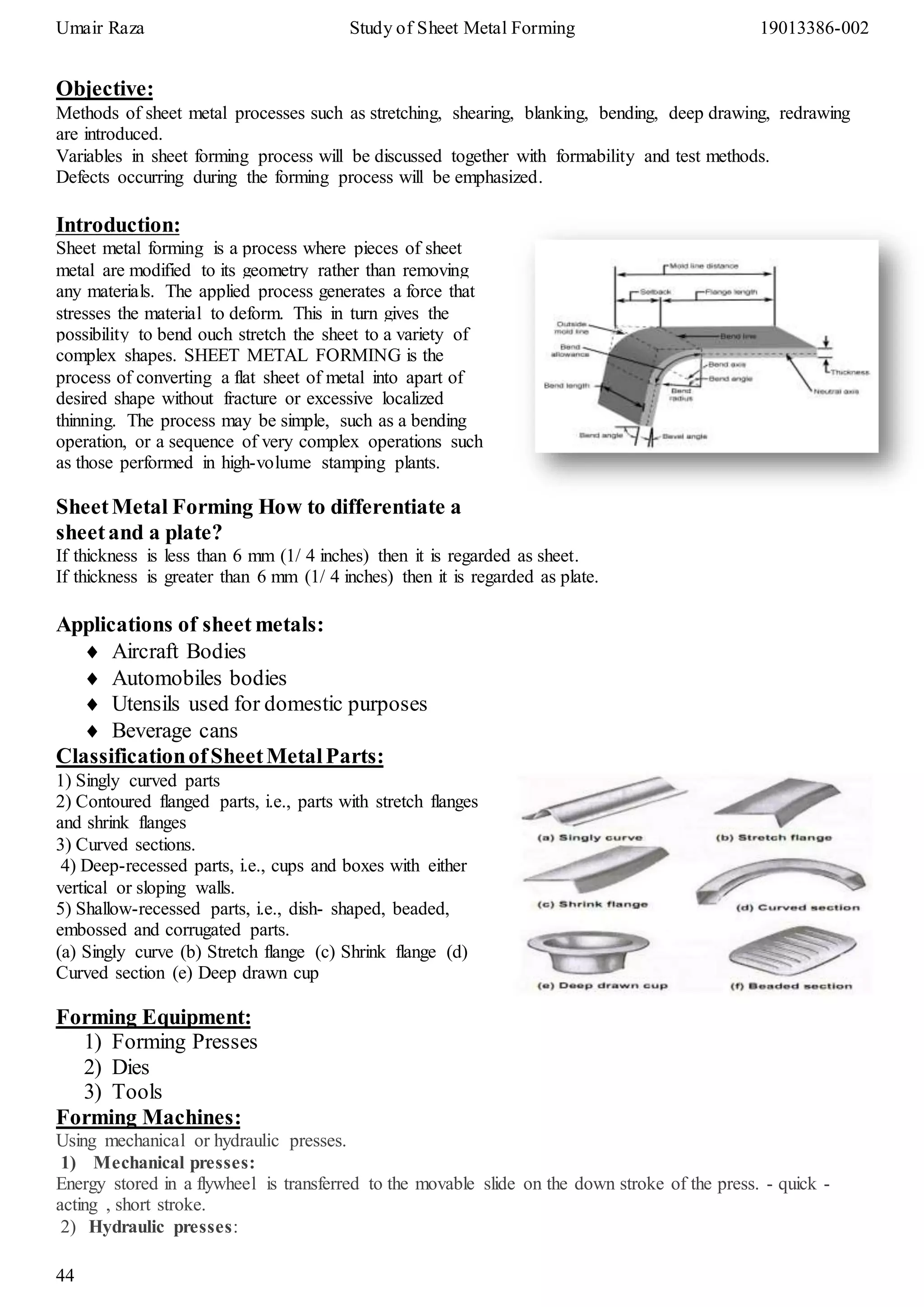

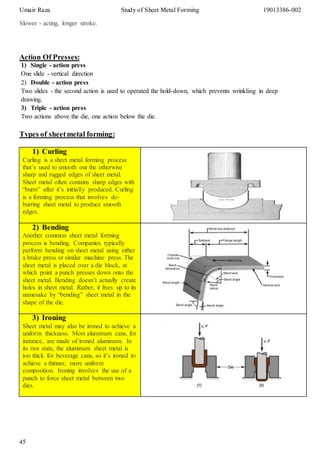

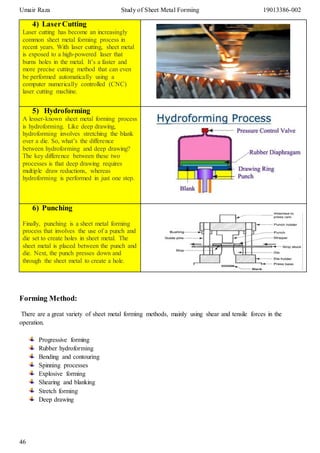

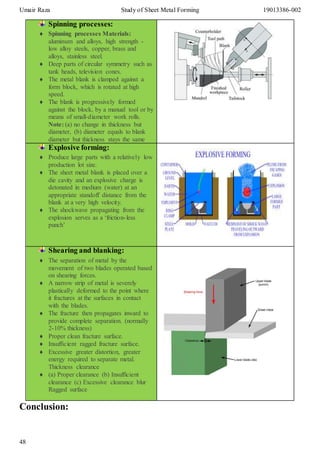

The document discusses various methods of sheet metal forming processes. It introduces stretching, shearing, blanking, bending, deep drawing, and redrawing. It then discusses variables in sheet forming processes and defects that can occur. The document provides classifications of sheet metal parts and describes various forming equipment and machines used. It also details different types of sheet metal forming processes like curling, bending, ironing, laser cutting, hydroforming, punching, progressive forming, rubber hydroforming, spinning, explosive forming, and stretching and deep drawing.