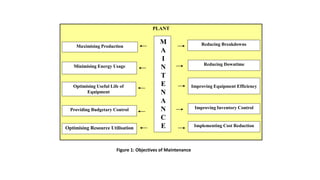

The document discusses maintenance of machinery and installation. It defines maintenance as actions to retain equipment in working condition or restore it to a state where it can perform its required function. The objectives of maintenance are to achieve minimum breakdowns and keep facilities operational at the lowest cost while ensuring availability. Different types of maintenance discussed are planned, unplanned, preventive, corrective, and predictive maintenance.