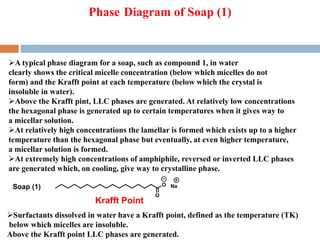

The seminar discussed various excipients used in pharmaceutical formulations. Excipients discussed included directly compressible vehicles like microcrystalline cellulose, lactose, and dicalcium phosphate dihydrate that allow direct compression of tablets without wet granulation. Surfactants were covered including their ability to form micelles above the critical micelle concentration and form liquid crystal phases. Newer excipients like cyclodextrins, ion exchange resins, and superdisintegrants were also mentioned along with standardization of excipients.

![3. Alginic acid:

Alginic acid is a tasteless, practically odorless, white to

yellowish white , fibrous powder. Alginic acid is a linear

glycuron an polymer consisting of a mixture of b-(1!4)-D-

mannosyluronic acid and a-(1!4)-L- gulosyluronic acid residues,

of general formula (C6H8O)n. The molecular weight is

typically 20 000–240 000. Alginic acid as a mixture of

polyuronic acids [(C6H8O6)n] composed of residues of D-

mannuronic and Lglucuronic acid, and obtained mainly from

algae belonging to the Phaeophyceae .](https://image.slidesharecdn.com/myppt-151004232702-lva1-app6891/85/Excipient-71-320.jpg)