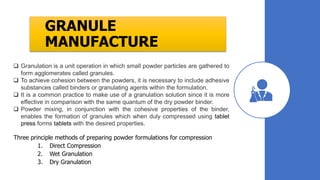

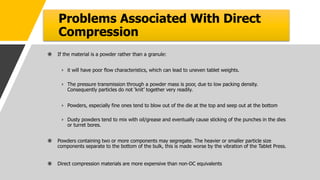

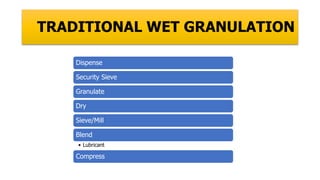

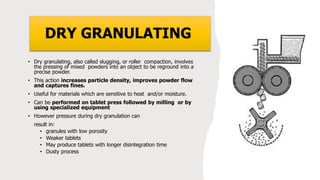

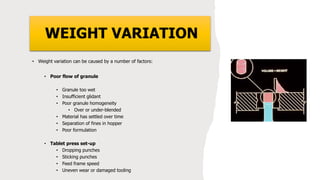

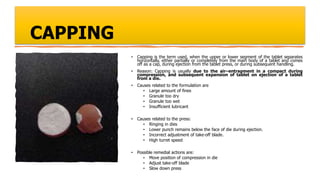

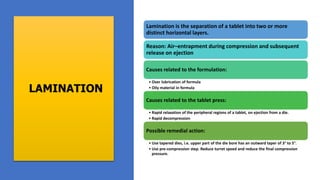

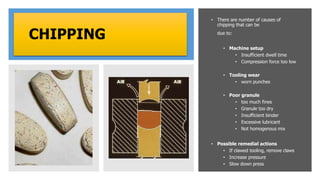

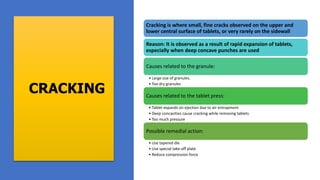

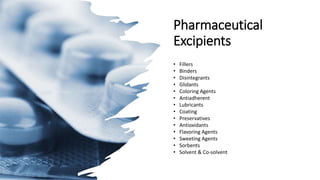

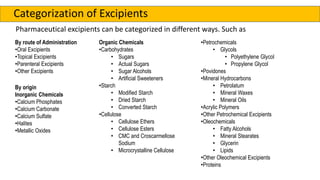

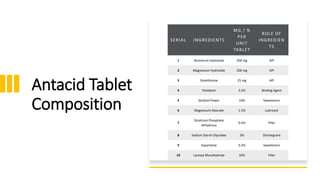

The document outlines various aspects of the pharmaceutical industry, emphasizing the importance of clean water and specialized raw materials such as active pharmaceutical ingredients (APIs) and excipients. It details manufacturing processes like direct compression and granulation, along with typical formulations and their key components, which influence tablet quality and performance. Additionally, it discusses common challenges encountered during tablet manufacturing, such as weight variation and capping, as well as potential remediation strategies.

![RECEIPT OF RAW

MATERIAL FROM STORE

VERIFICATION OF

MATERIAL & WEIGHTS AT

SHOP FLOOR

SIFTING OF INVIDUAL

MATERIAL

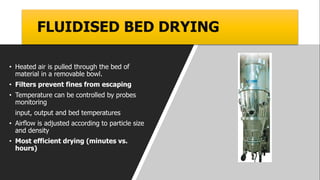

DRYING

MILLING/ GRANULE

SIZING

LUBRICATION/BLENDING[

YIELD CALCULATION]

COMPRESSION

[SIMULTANEOUS

OBSERVATIONS BY

PROD.&IPQA]

VISUAL INSPECTON

[YEILD ANALYSIS]

COATING

[SIMULTANEOUS

OBSERVATIONS ON EACH

LOT BY PROD.&IPQA]

VISUAL INSPECTION

[YEILD ANALYSIS]

PM VERIFICATION AND

BATCH CODING

PACKING

[SIMULTANEOUS

OBSERVATIONS BY

PROD.&IPQA]

FINISHED GOOD

ANALYSIS

TRANSFER TO F.G.STORE

[BPR TO QA]

FLOW CHART TABLET MANUFACTURING AND

PACKING](https://image.slidesharecdn.com/pharmaceuticalsindustry-231117181213-a9e0ca92/85/Pharmaceuticals-Industry-7-320.jpg)