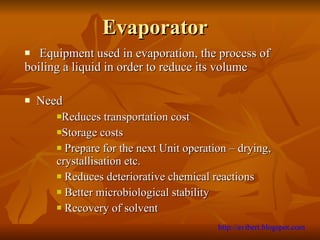

Evaporators are used to reduce the volume of a liquid by boiling it. This concentrates the liquid and removes solvents. There are different types of evaporators that use heat exchange and decreasing pressure between effects to boil liquids. Key components include a heat exchanger, vacuum system, vapor separator and condenser. Process factors like material properties, temperatures, and pressures must be considered during evaporator operation.