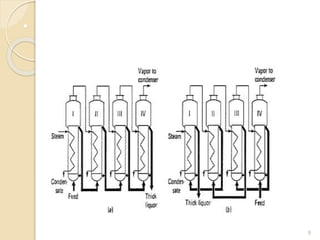

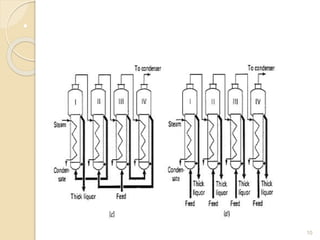

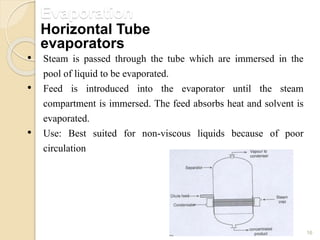

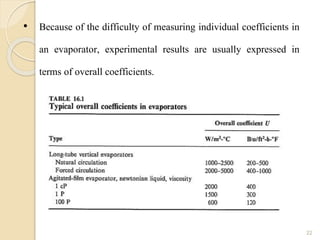

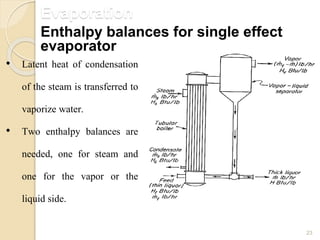

Evaporation is a separation process where a solvent is vaporized from a solution to concentrate it. There are several types of evaporators used in evaporation, including horizontal tube evaporators, vertical tube evaporators, and climbing film evaporators. Multiple effect evaporators can reuse vapor from one effect in the next to improve heat economy. Evaporation finds applications in industries like sugar production, dairy processing, fertilizer production, and petroleum refining to separate and concentrate components.