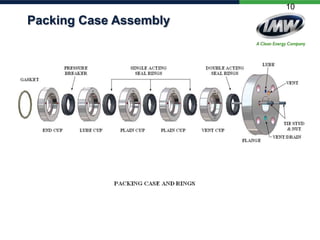

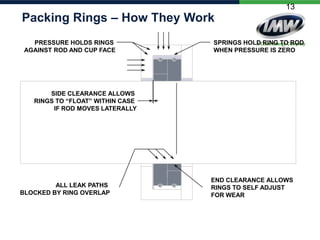

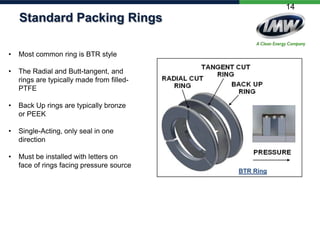

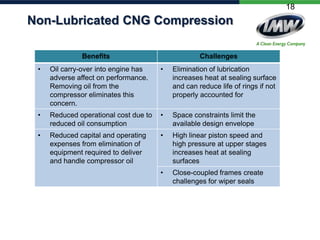

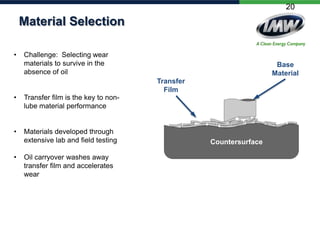

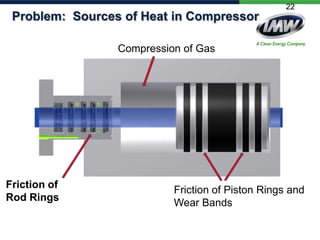

The document discusses the critical components and design considerations of non-lubricated compression equipment for natural gas, presented by experts from IMW Industries and Cook Compression. It highlights the benefits and challenges of non-lubricated CNG compression, emphasizing material selection and seal design to extend service life. Key takeaways include the importance of managing heat and oil carryover to maximize compressor longevity and the focus on standardized designs for improved performance.