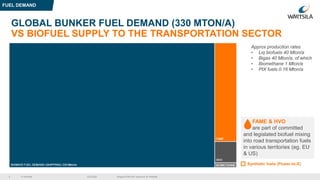

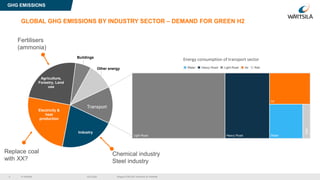

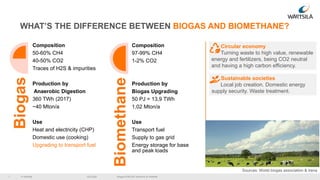

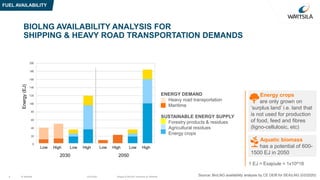

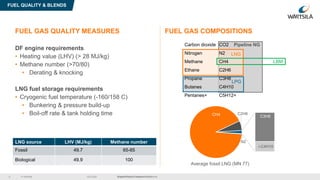

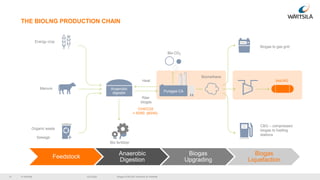

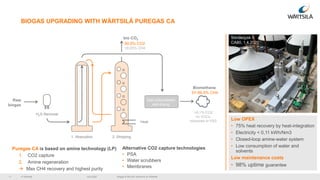

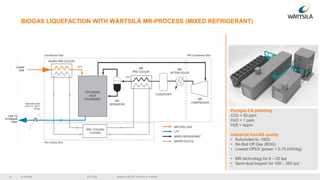

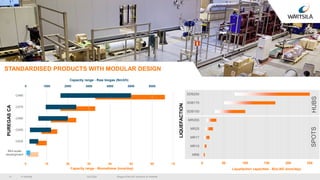

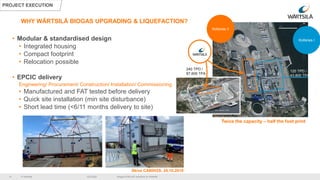

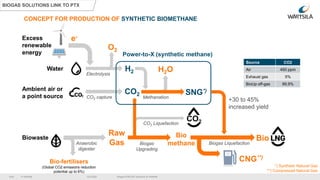

This document discusses Wärtsilä's biogas and BioLNG solutions. It provides an overview of biogas and biomethane production processes including anaerobic digestion, biogas upgrading, and liquefaction. Statistics on biogas potential and production are presented. Wärtsilä's Puregas upgrading and MR liquefaction technologies are described. The document also discusses the role of biogas and BioLNG in reducing emissions from transportation and as a transition fuel for shipping. Case studies of Wärtsilä biogas projects are briefly summarized.